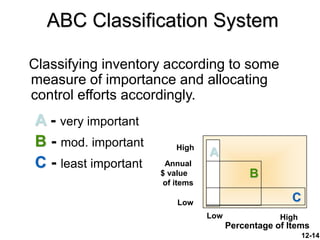

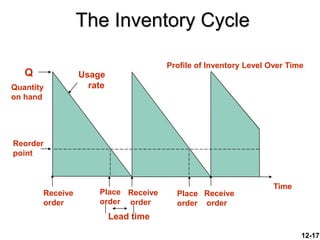

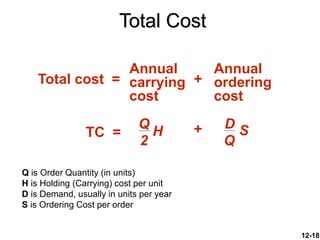

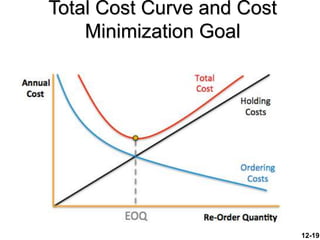

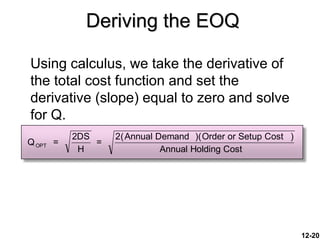

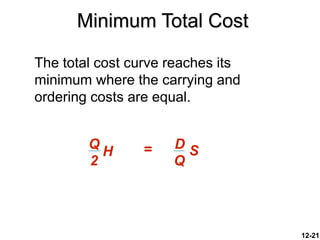

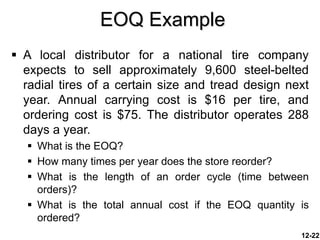

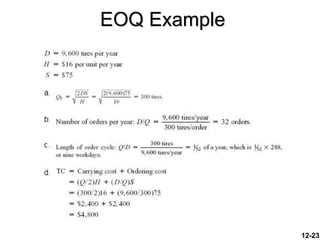

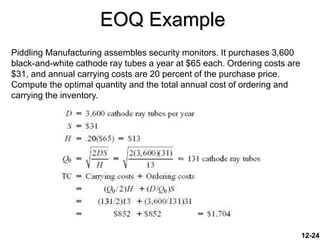

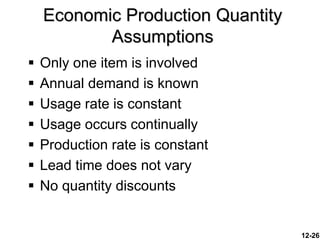

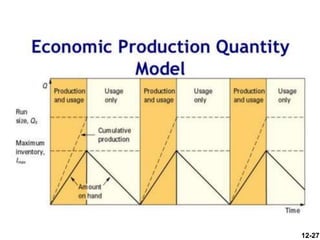

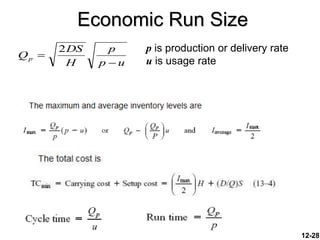

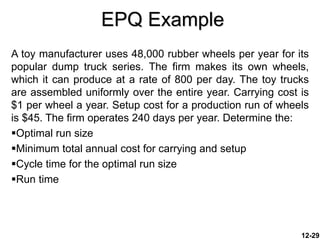

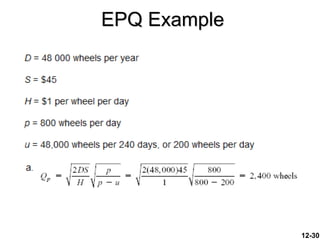

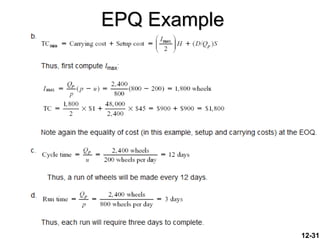

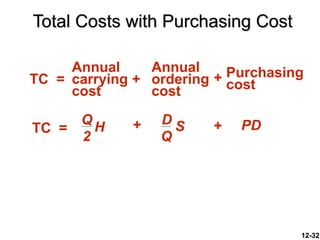

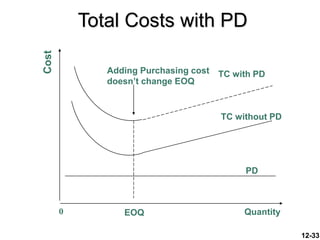

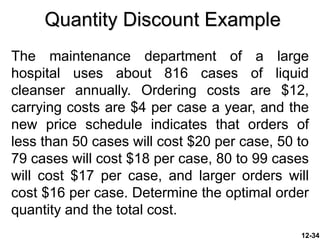

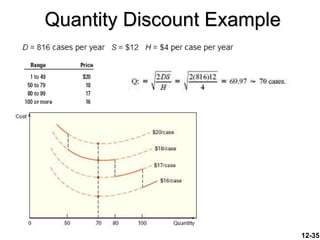

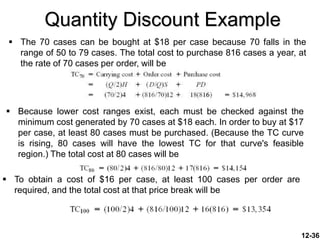

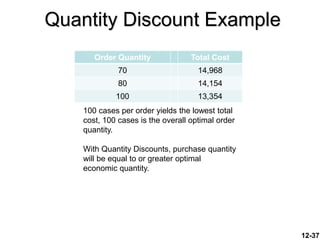

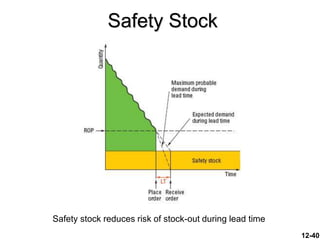

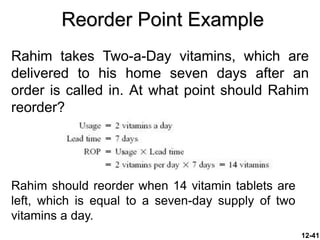

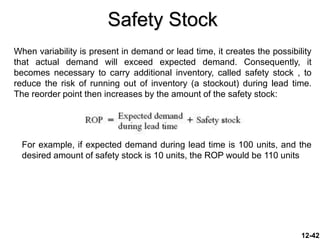

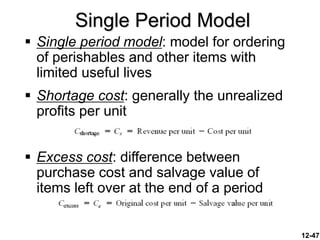

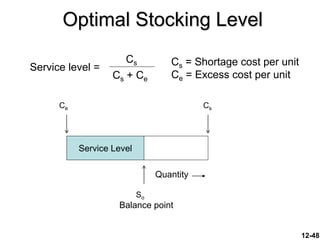

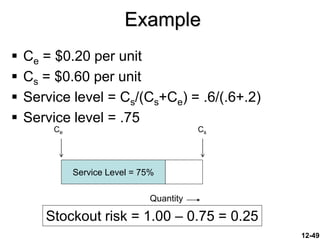

The document discusses key concepts in inventory management. It begins by defining inventory and listing the major reasons for holding inventory. It then discusses objectives of inventory management, including achieving satisfactory customer service levels while keeping costs low. The document covers inventory models like economic order quantity (EOQ) and economic production quantity (EPQ), which can be used to determine optimal order sizes. It also discusses classification systems, inventory counting methods, key terms, and factors that influence reorder points.