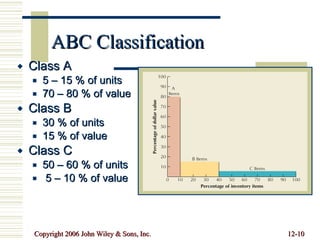

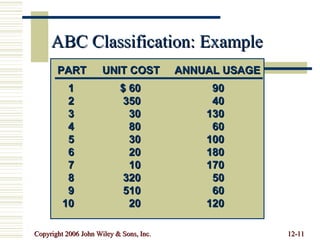

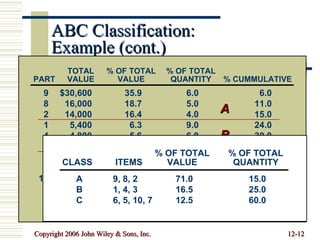

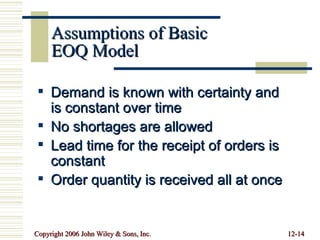

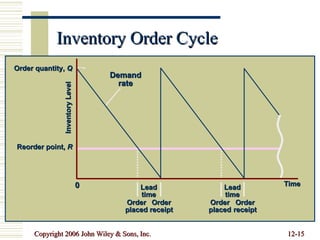

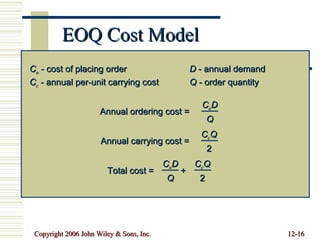

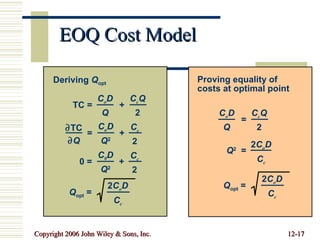

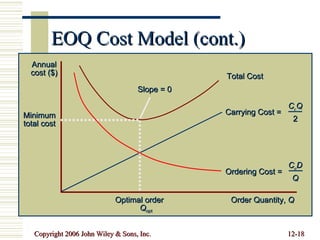

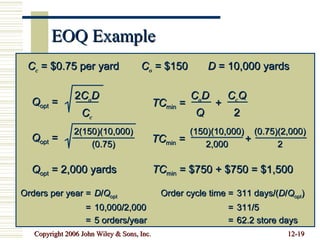

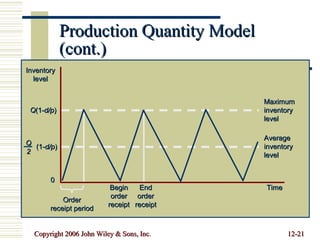

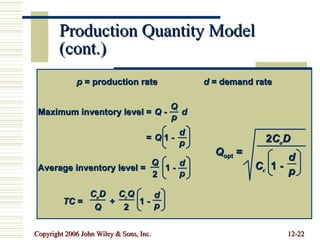

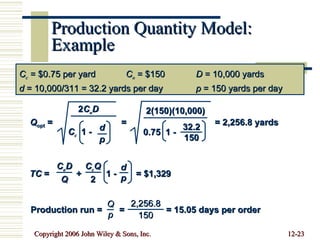

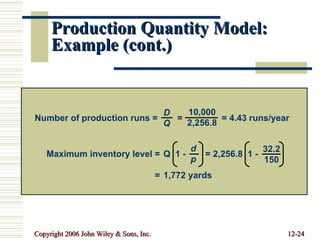

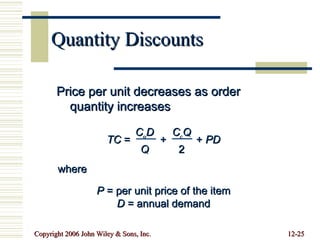

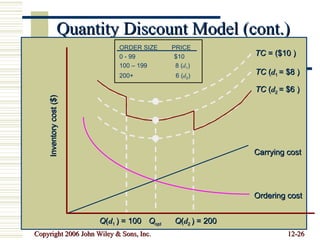

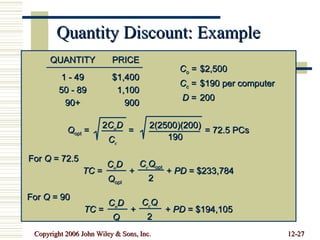

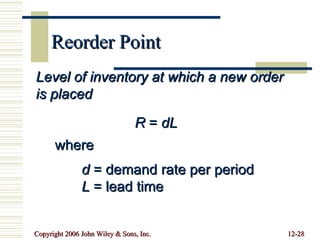

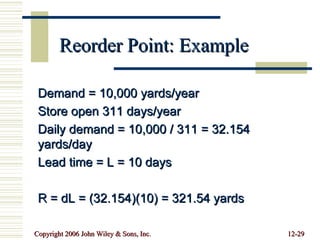

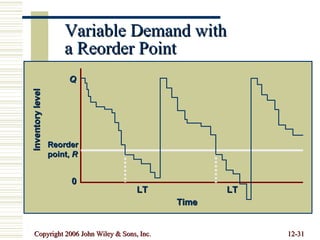

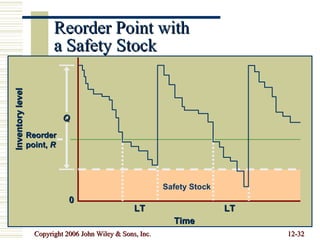

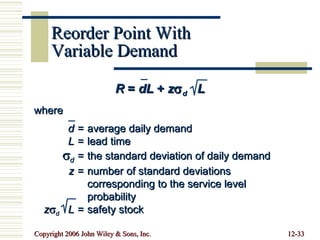

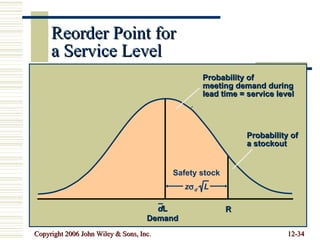

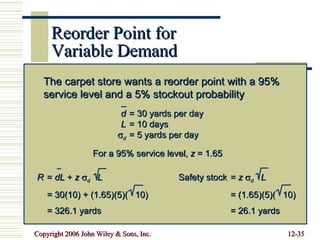

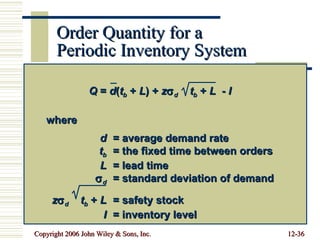

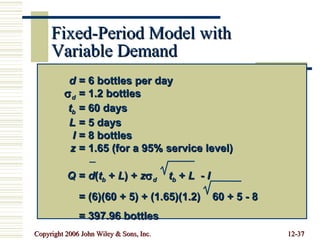

This document summarizes key concepts in inventory management including inventory control systems, economic order quantity models, reorder points, safety stocks, and periodic inventory systems. It discusses the costs of inventory like carrying costs and ordering costs. It also covers topics like ABC classification, quantity discounts, and order quantities for systems with variable demand.