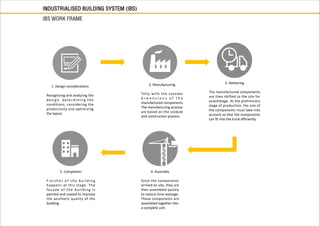

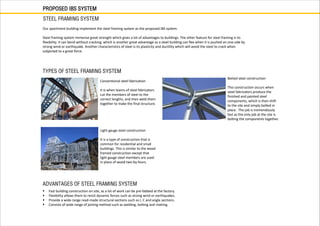

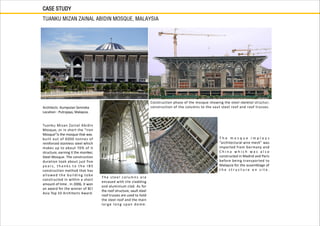

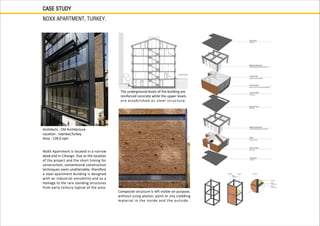

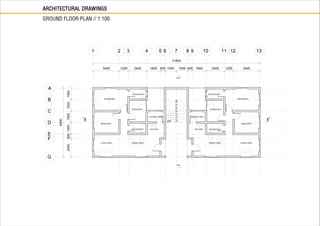

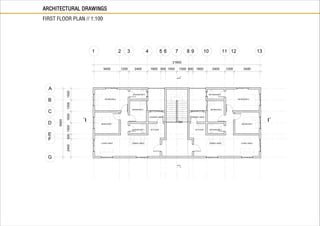

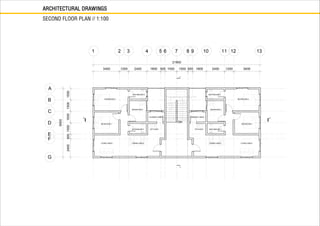

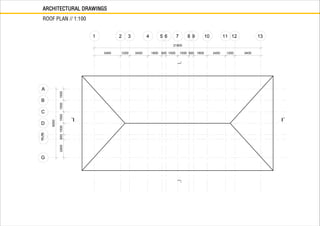

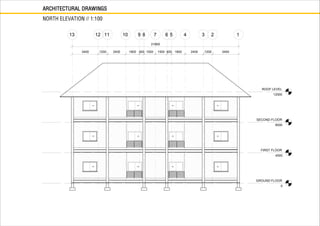

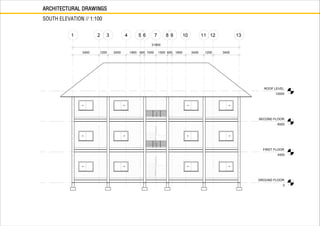

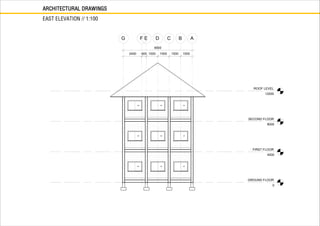

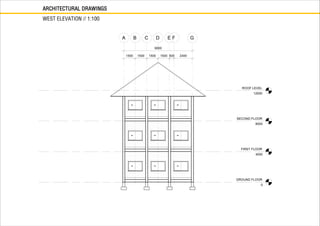

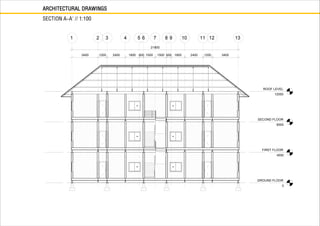

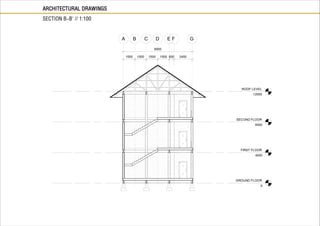

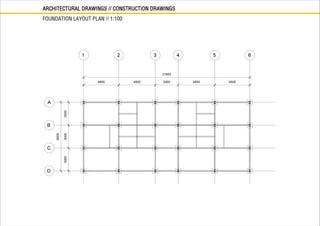

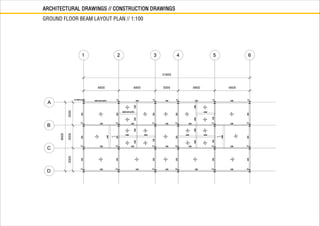

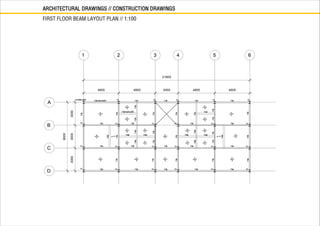

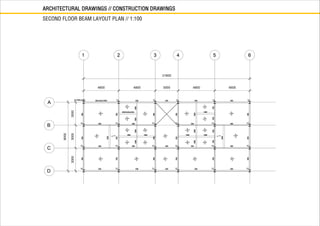

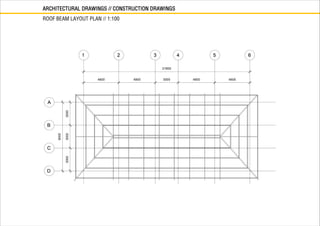

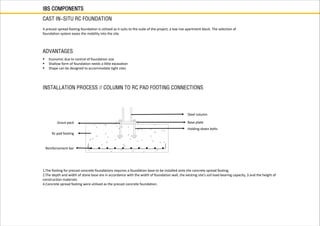

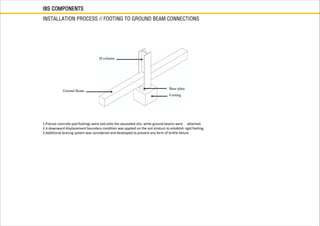

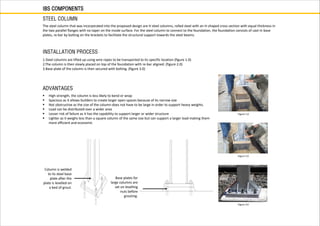

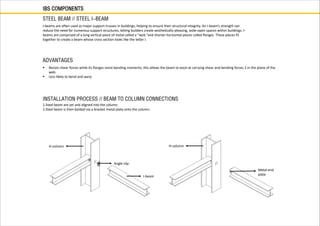

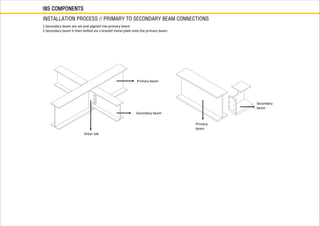

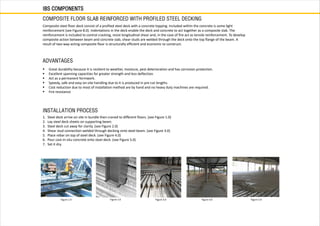

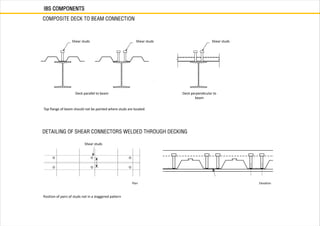

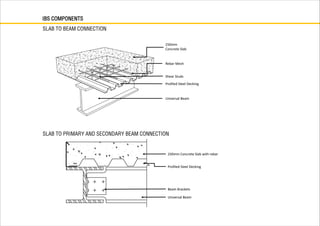

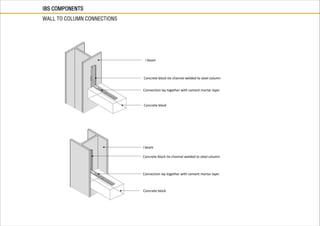

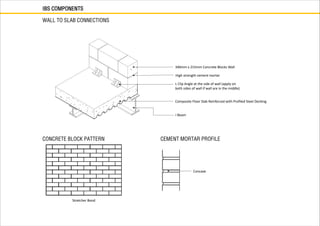

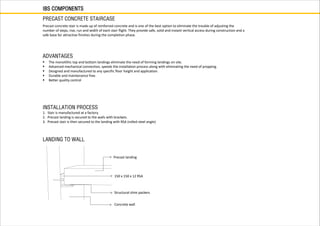

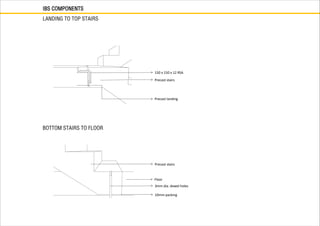

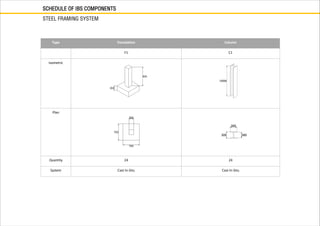

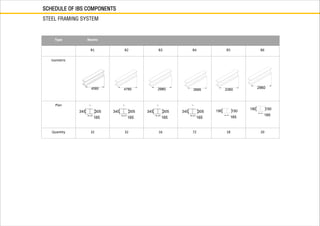

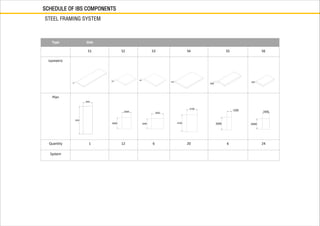

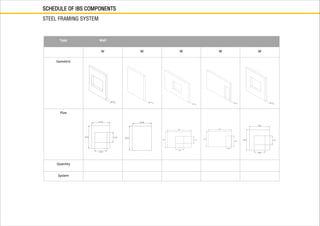

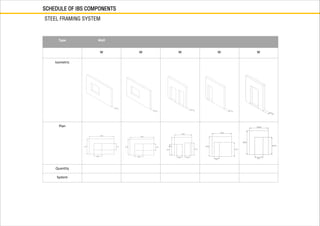

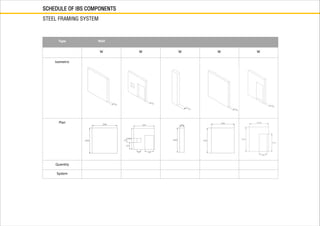

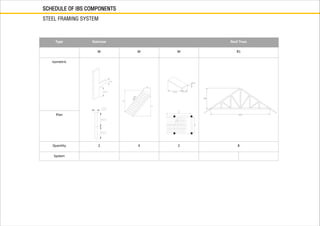

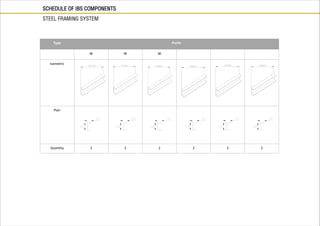

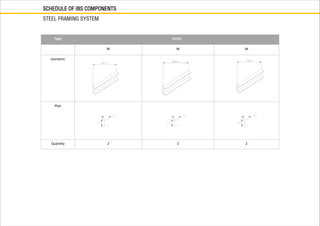

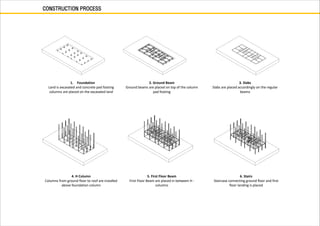

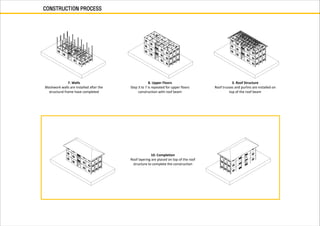

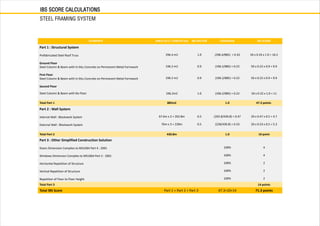

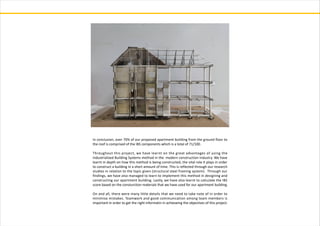

The document provides details on the proposed use of an industrialized building system (IBS) for an apartment building project. It discusses the steel framing system that will be implemented, including the use of H-shaped steel columns, I-beams, and a composite floor slab reinforced with profiled steel decking. Case studies of other projects using similar IBS approaches are presented, along with architectural drawings of the project plans, elevations, and construction drawings. Components of the proposed IBS system like foundations, beams, and connections are described.