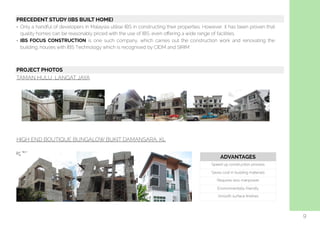

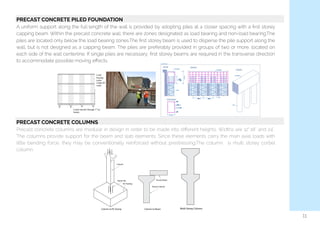

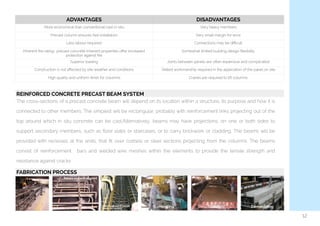

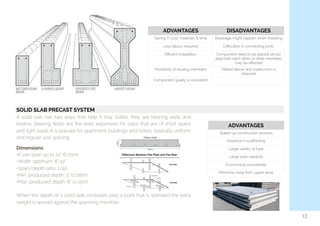

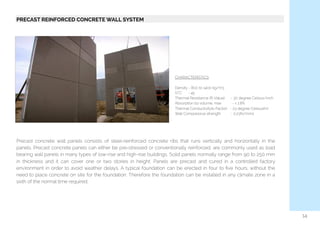

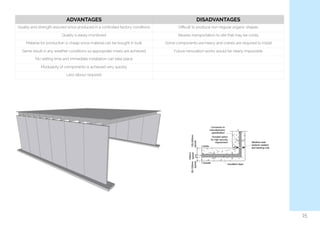

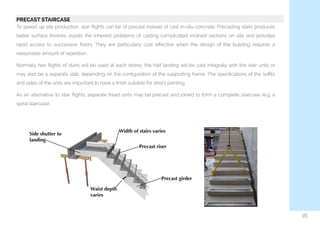

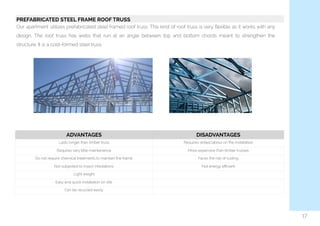

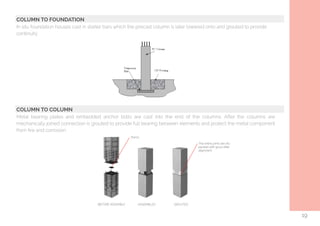

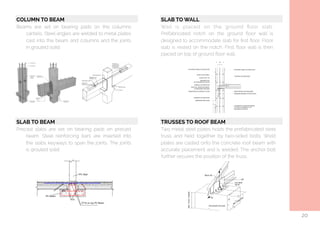

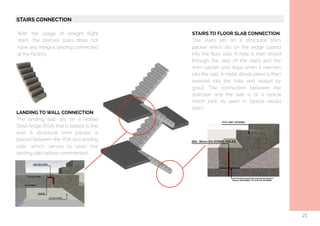

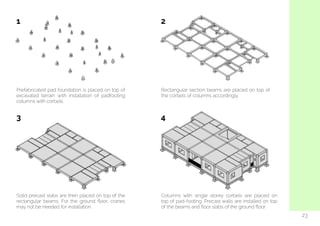

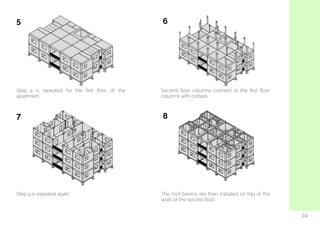

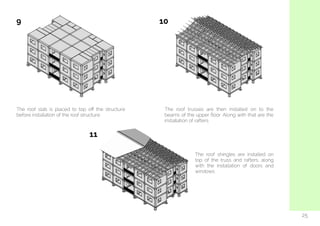

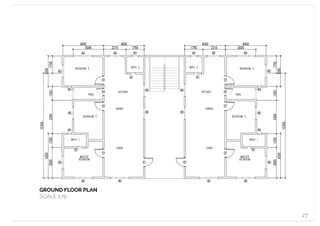

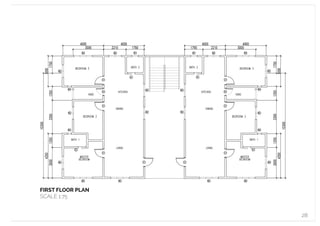

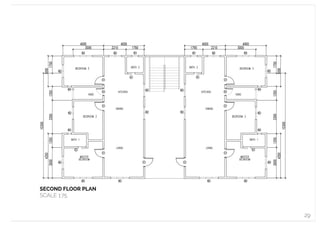

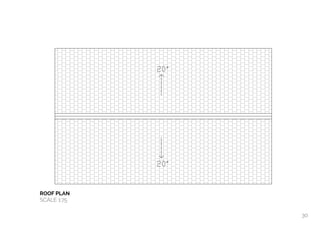

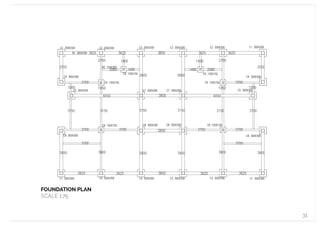

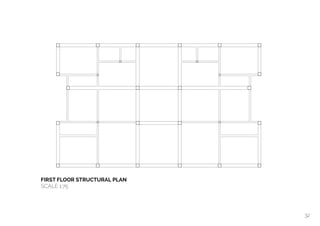

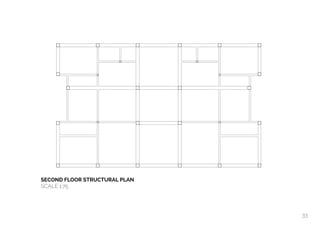

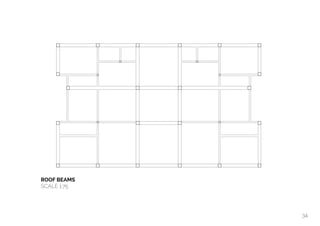

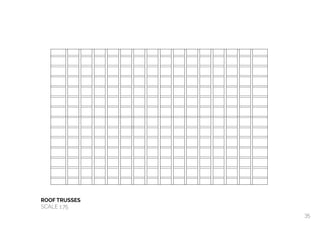

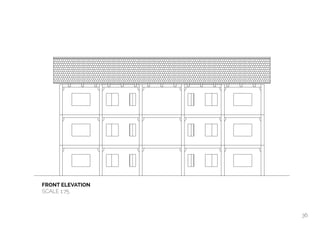

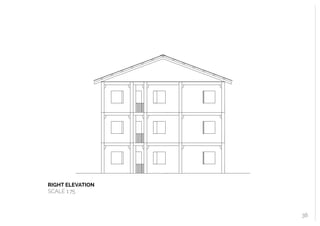

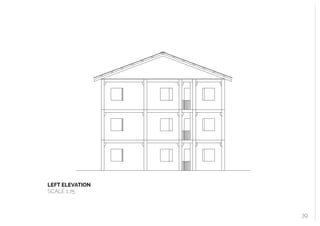

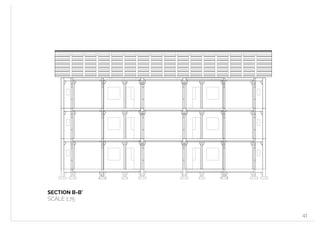

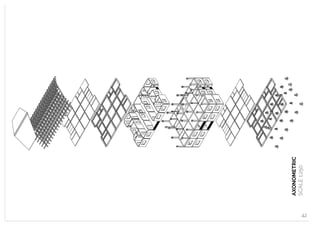

This document presents the work of a group of students on their project exploring Industrialized Building Systems (IBS) construction methods. It includes an introduction, proposed precast concrete and steel precast systems using IBS, precedent studies of IBS buildings, descriptions of building components like foundations and walls that would be used, joining methods, construction procedures, drawings, and references. The group analyzed the use of precast concrete piles, beams, walls and slabs alongside prefabricated steel roof trusses to construct a 3-storey apartment building using IBS methods. Connections between elements and the construction sequence are detailed.