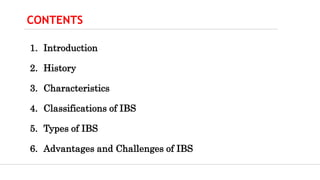

(1) Industrialized building systems (IBS) involve constructing buildings using prefabricated components manufactured in a controlled environment.

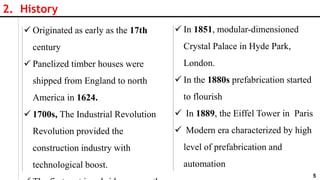

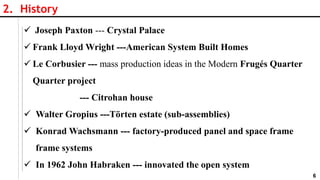

(2) The history of IBS dates back to the 17th century with panelized timber houses shipped from England to North America. Major developments include the Crystal Palace in 1851 and modern era characterized by high levels of prefabrication and automation.

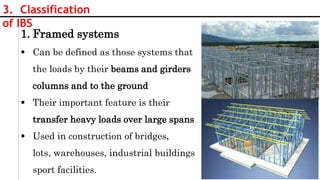

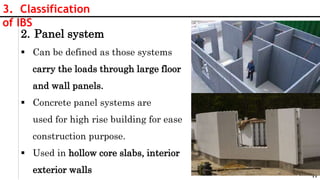

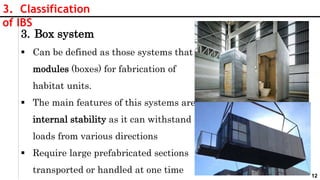

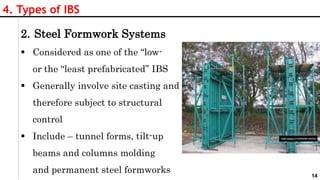

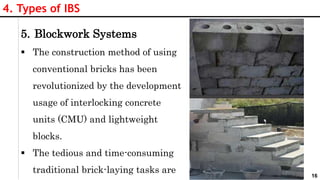

(3) IBS can be classified into framed systems, panel systems, and box systems depending on how components are assembled and loads are transferred. Common types include precast concrete, steel formwork, and prefabricated timber framing systems.