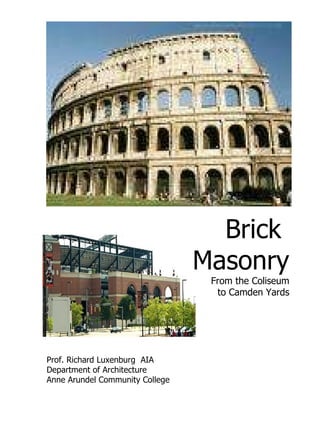

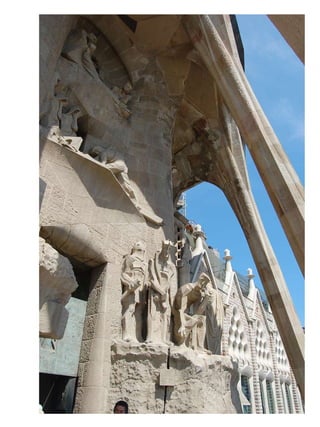

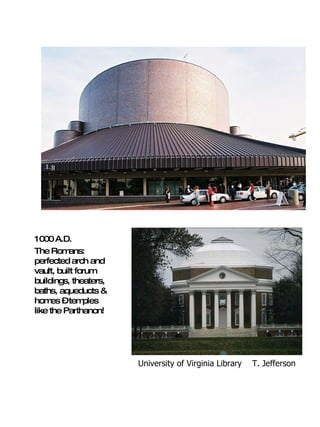

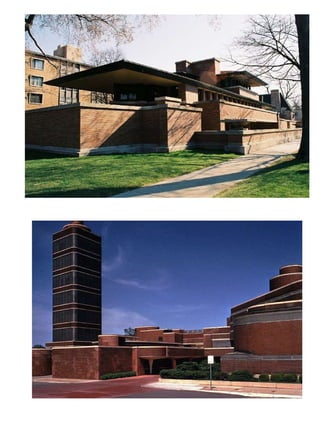

1. The document discusses the history of brick masonry from ancient Roman structures to modern buildings like Camden Yards.

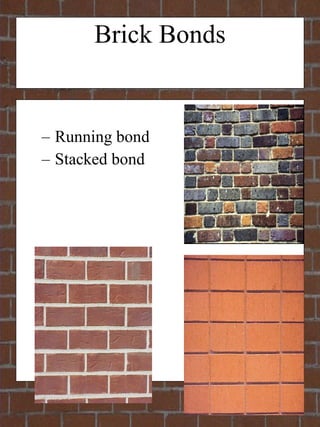

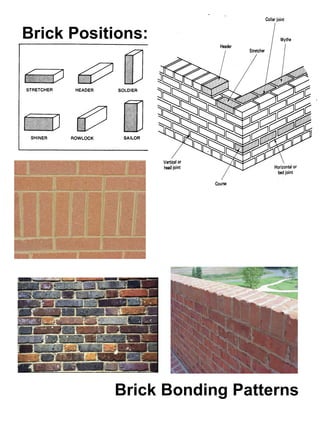

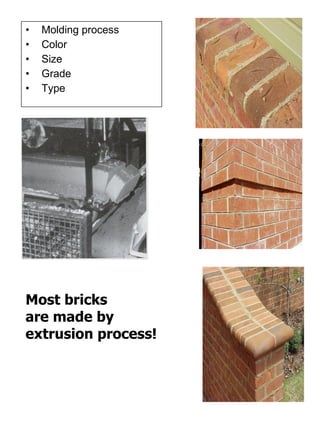

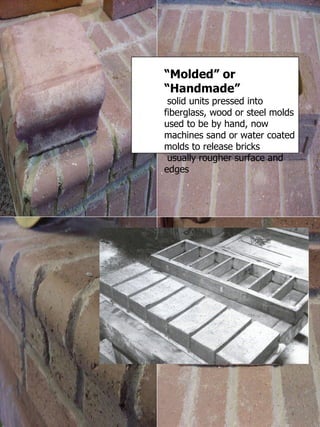

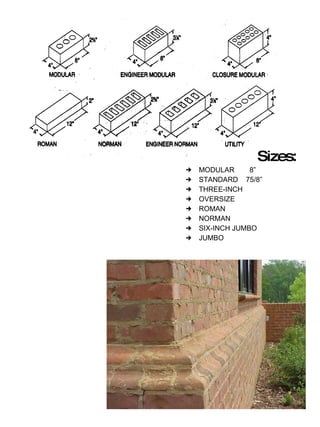

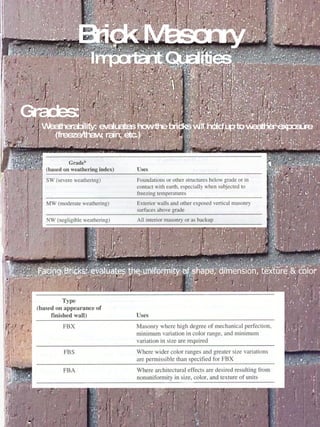

2. It covers various brick bonding patterns, sizes, grades, and qualities as well as the brick making process.

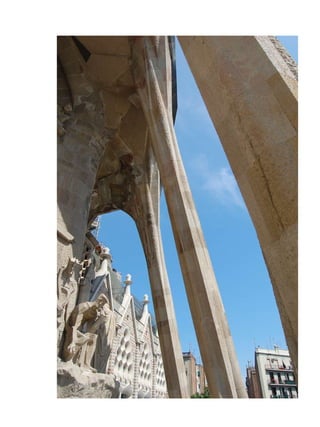

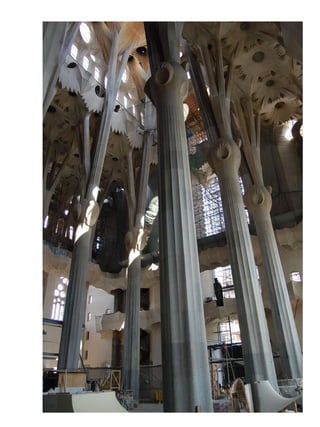

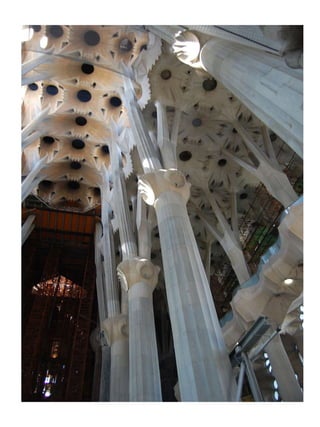

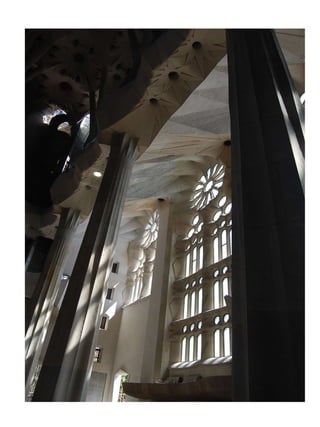

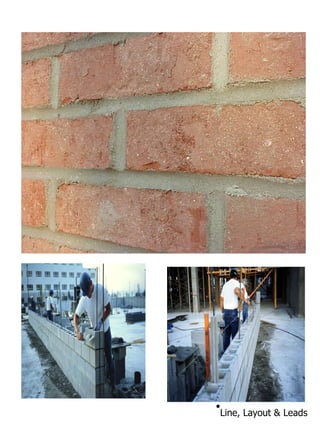

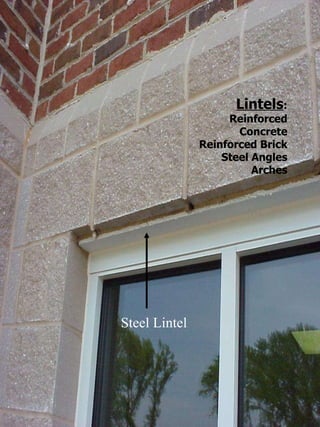

3. The key components of brick masonry are also summarized, including mortar, joints, scaffolding, and structural elements like arches and lintels.