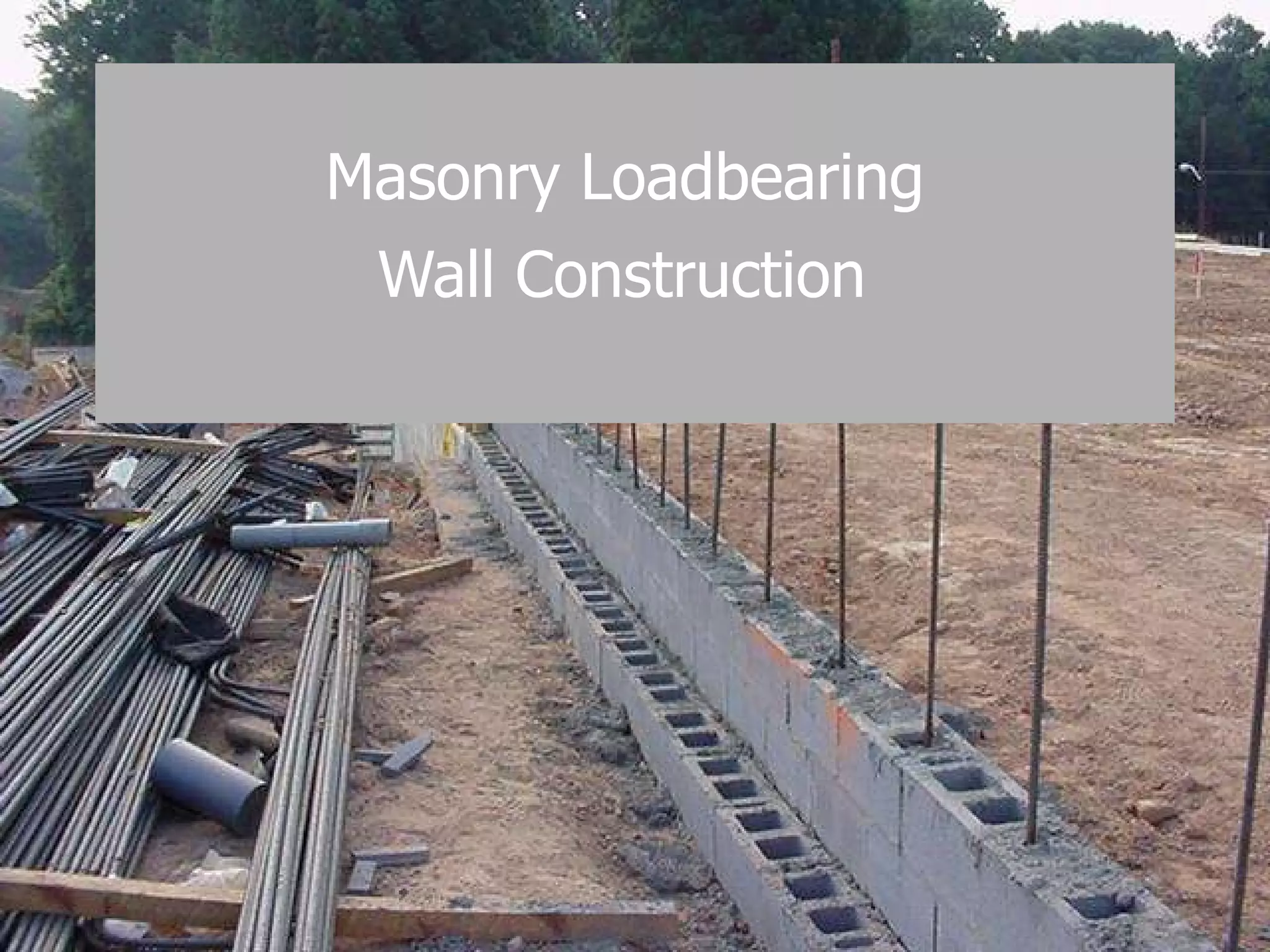

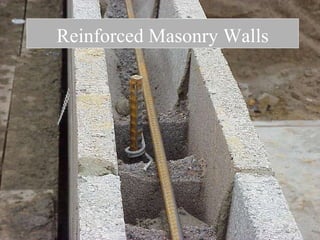

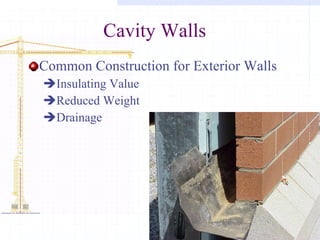

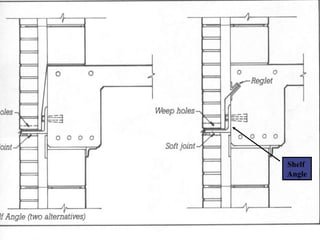

Masonry loadbearing walls can be reinforced or unreinforced, with reinforcement increasing the load carrying capacity. There are different types of masonry walls including single wythe solid walls, cavity walls with an inner and outer wythe separated by air space, and composite walls made of two different materials. Cavity walls provide insulation and drainage benefits. Masonry walls require flashing at openings and shelf angles to prevent moisture penetration. Thermal insulation can be installed inside the wall cavity, in hollow cores, or on the exterior face. Masonry construction involves integrating masonry walls with other building materials like wood, steel, and concrete.