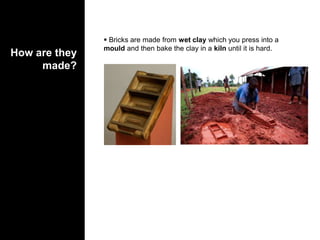

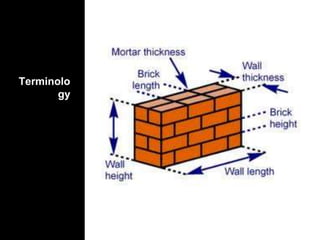

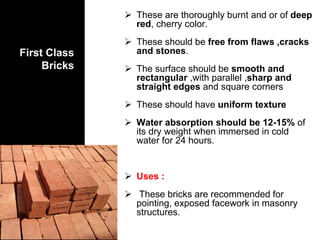

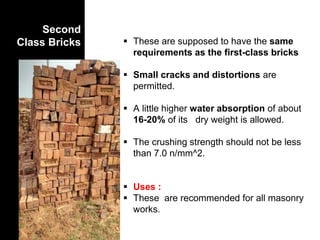

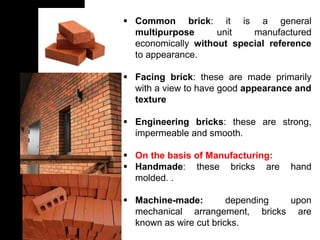

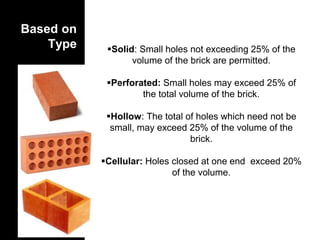

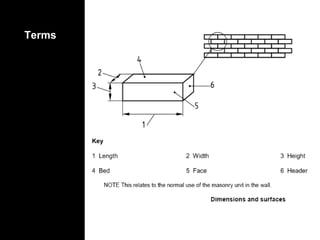

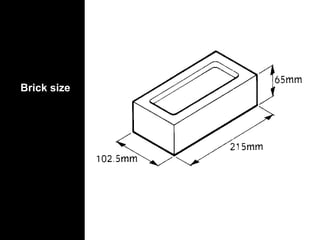

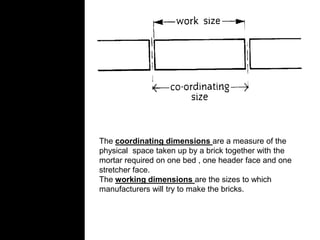

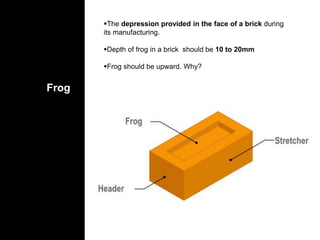

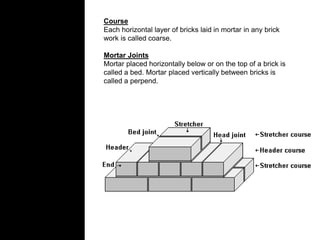

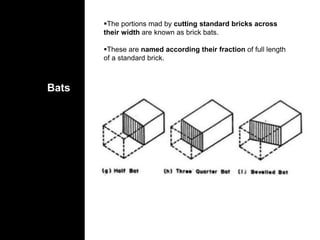

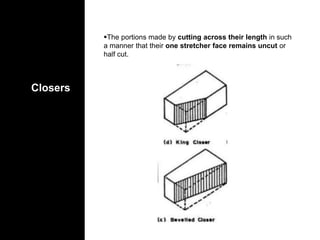

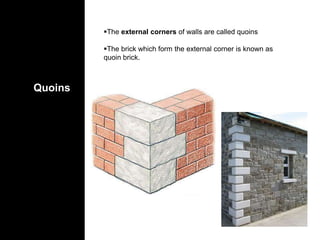

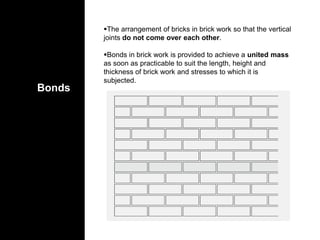

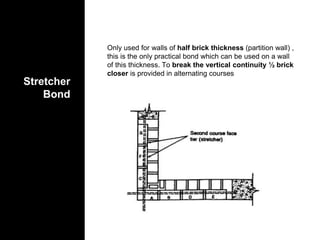

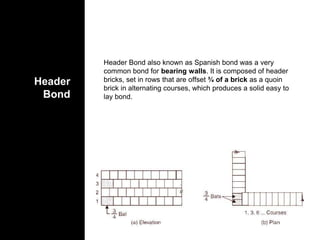

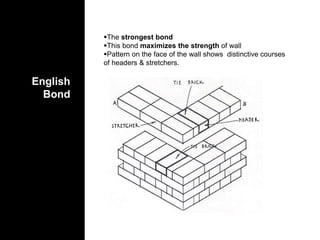

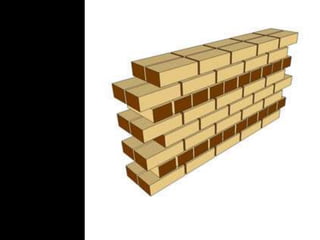

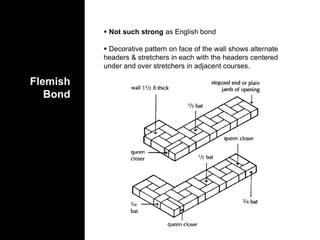

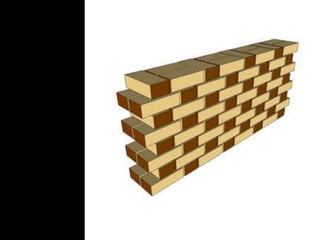

The document provides an overview of bricks and brick masonry, detailing their classification, manufacturing processes, and various types including first class, second class, and engineering bricks. It also explains the terminology related to brickwork, such as mortar joints, frog, and bonds, and outlines the functional requirements of masonry walls. Additionally, it describes different brick bonds used in construction, such as stretcher bond, header bond, English bond, and Flemish bond.