Embed presentation

Downloaded 42 times

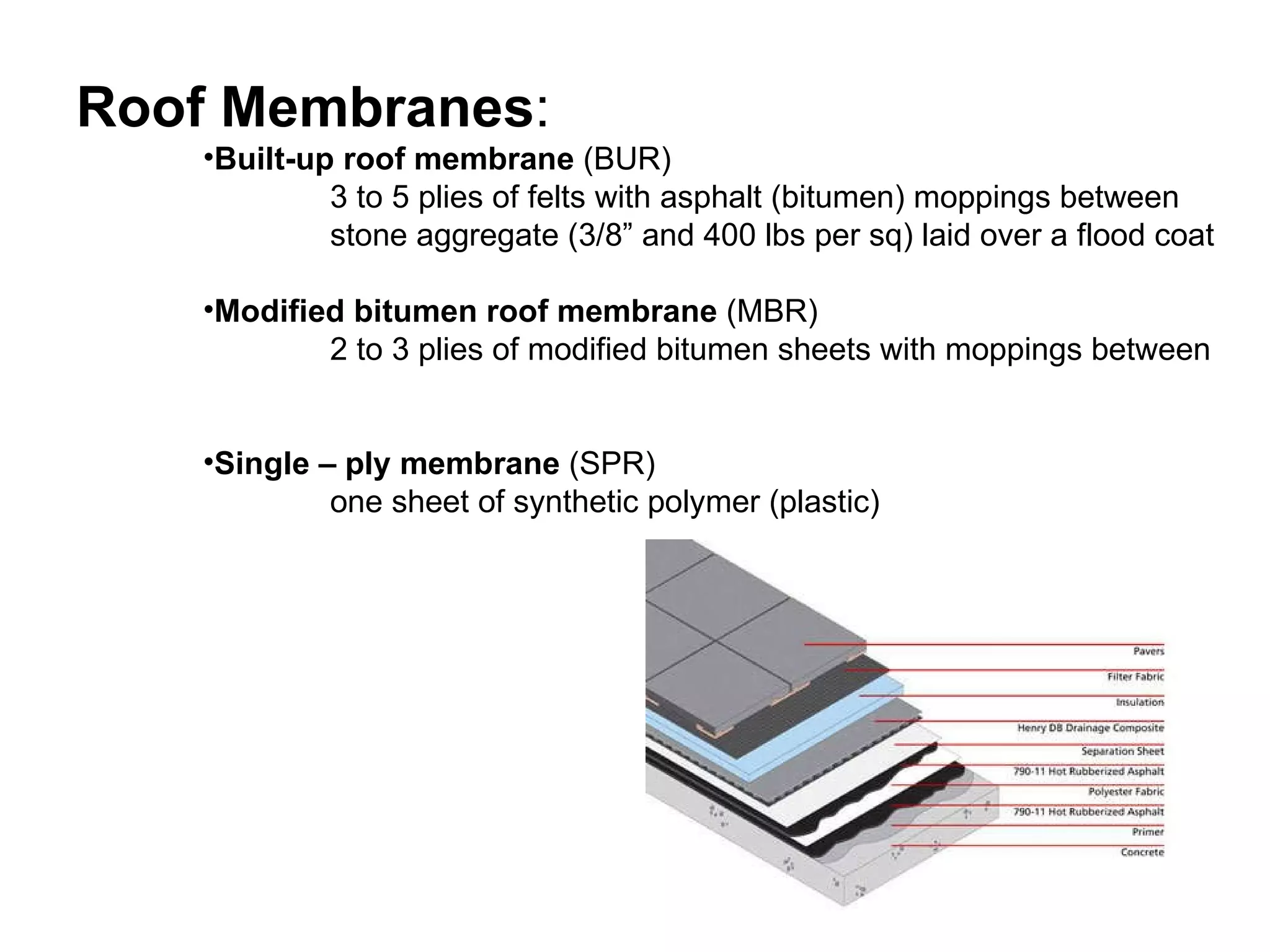

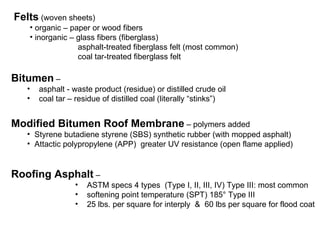

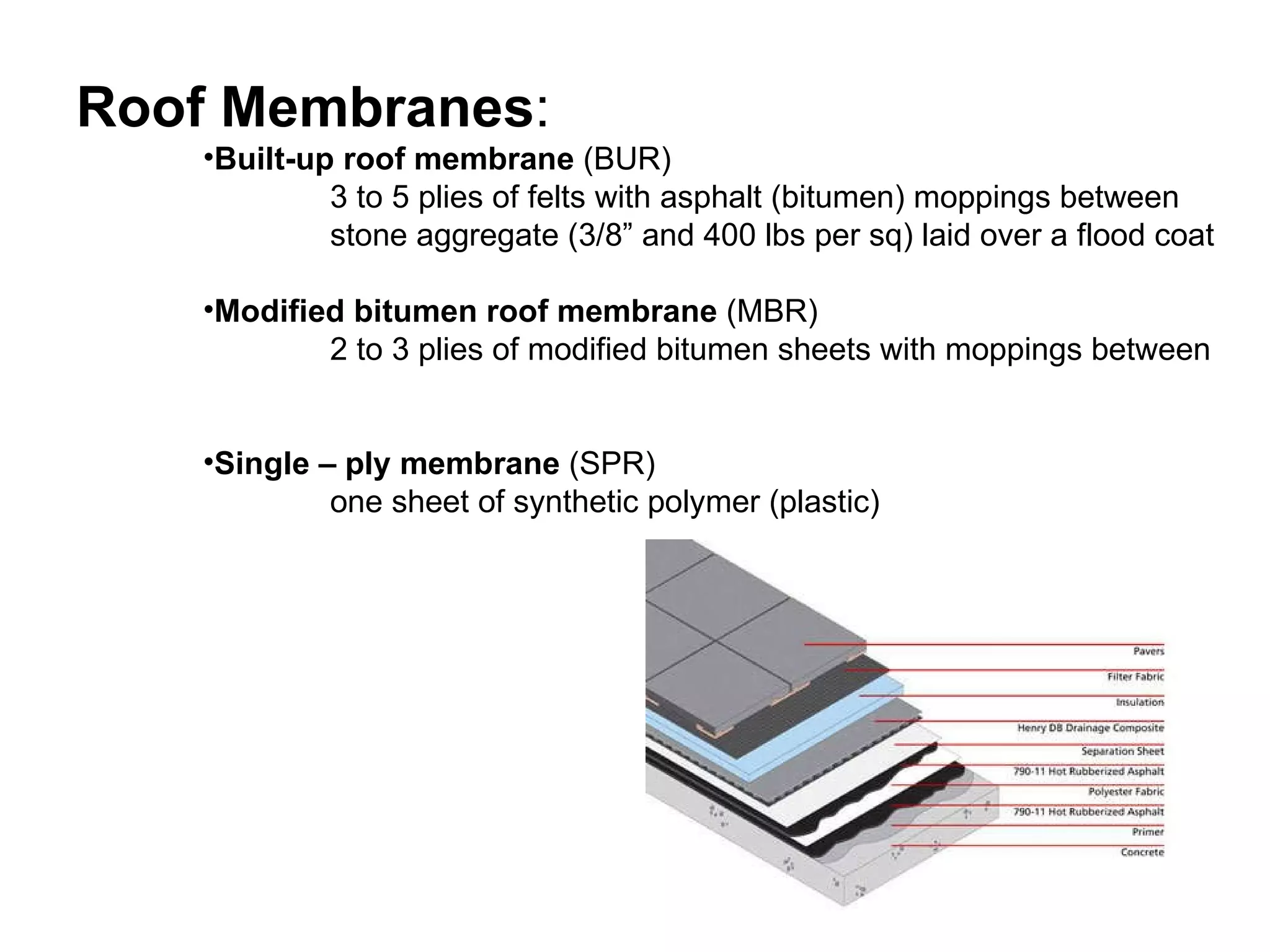

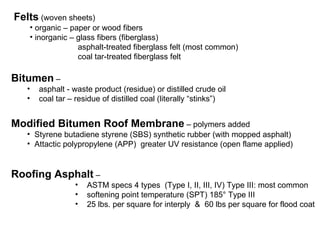

The document discusses different types of roof membranes, including built-up roof (BUR) membranes made of multiple felts and asphalt layers, modified bitumen roof (MBR) membranes made of polymer-modified asphalt sheets, and single-ply roof (SPR) membranes made of synthetic polymer sheets. It also describes some common polymers used in modified bitumen membranes like SBS and APP and materials used in felts like organic fibers, glass fibers, and asphalt or coal tar coatings. Finally, it mentions two common types of single-ply membranes - EPDM, a synthetic rubber membrane, and PVC or TPO thermoplastic membranes.