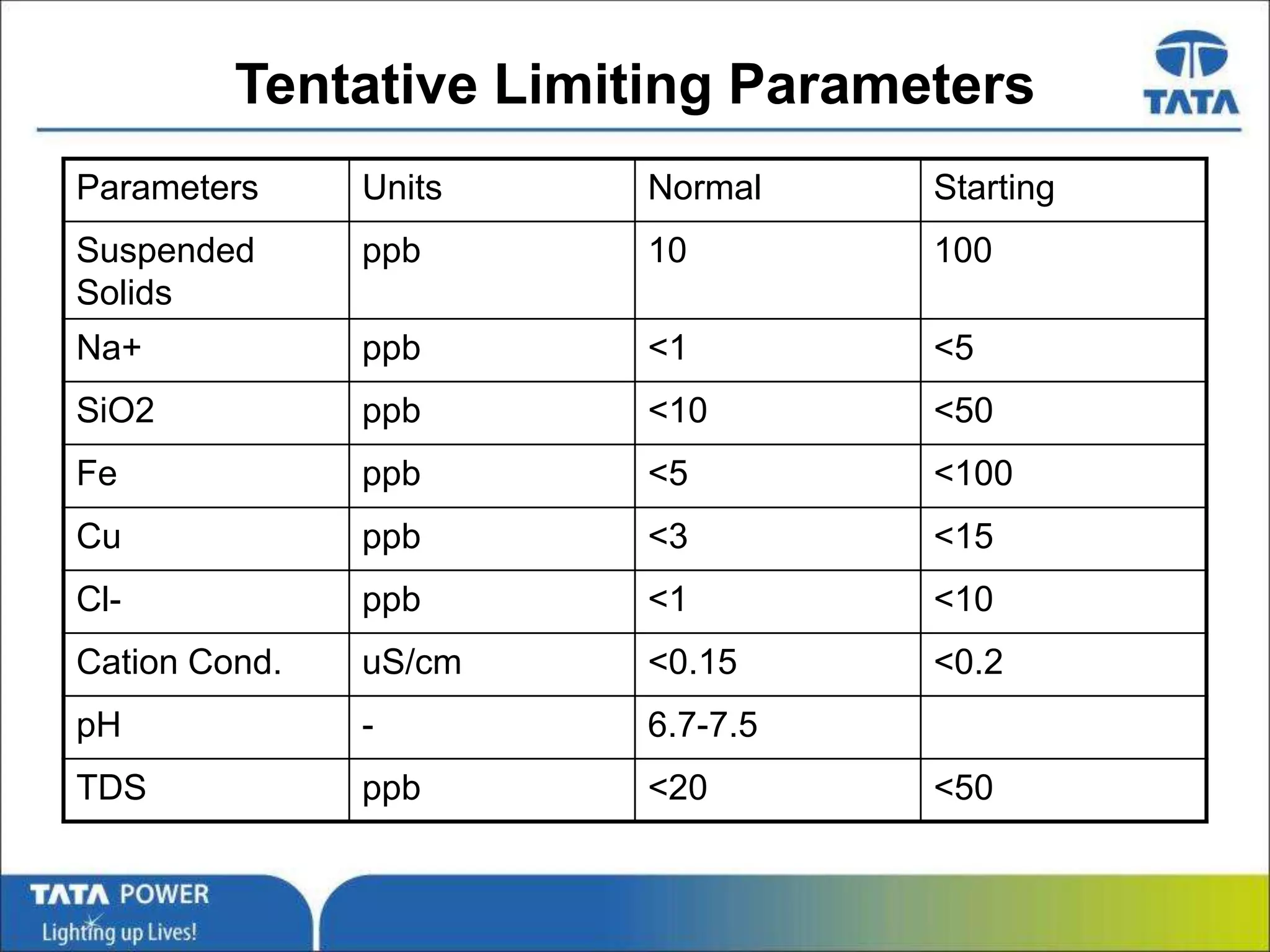

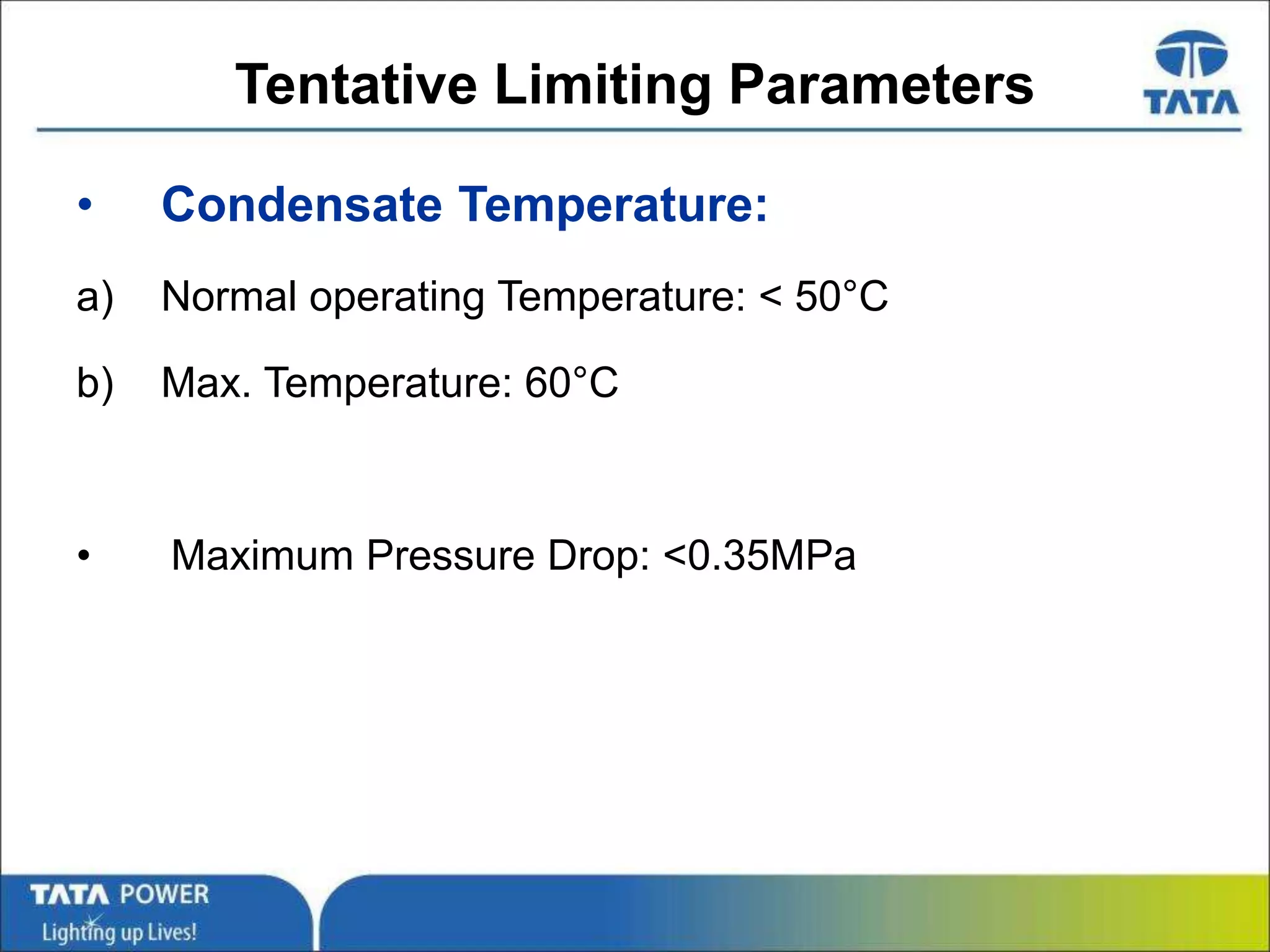

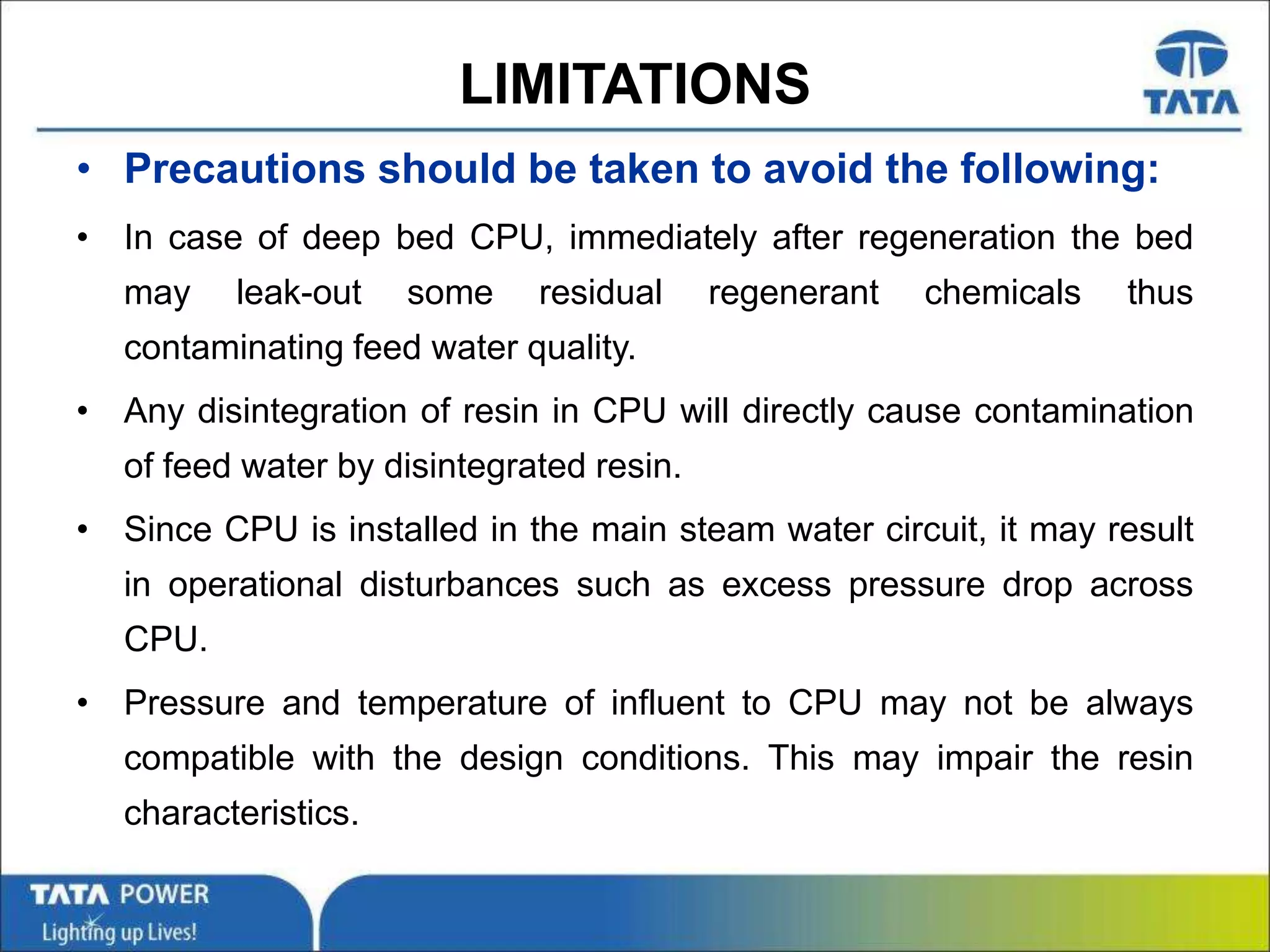

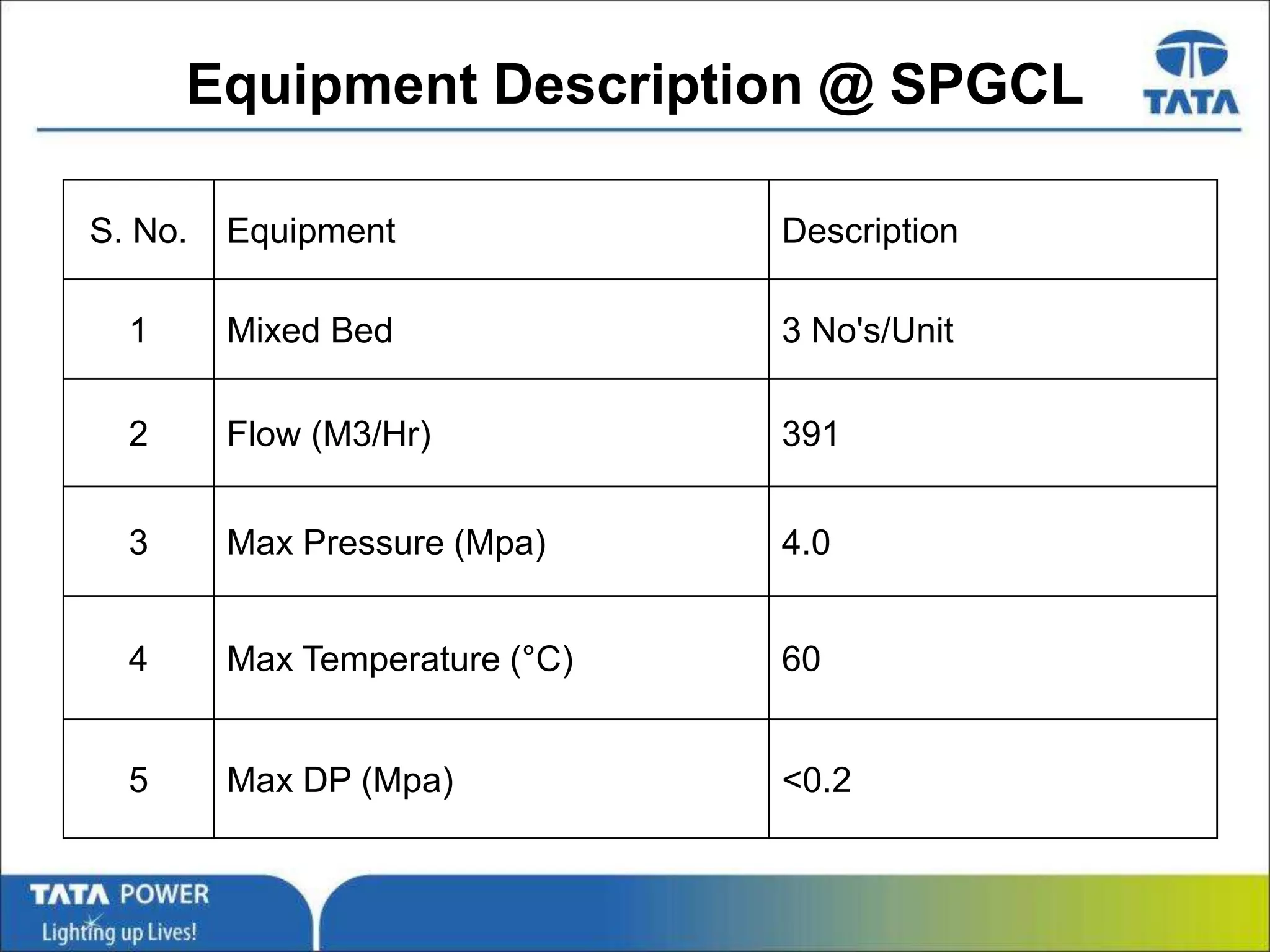

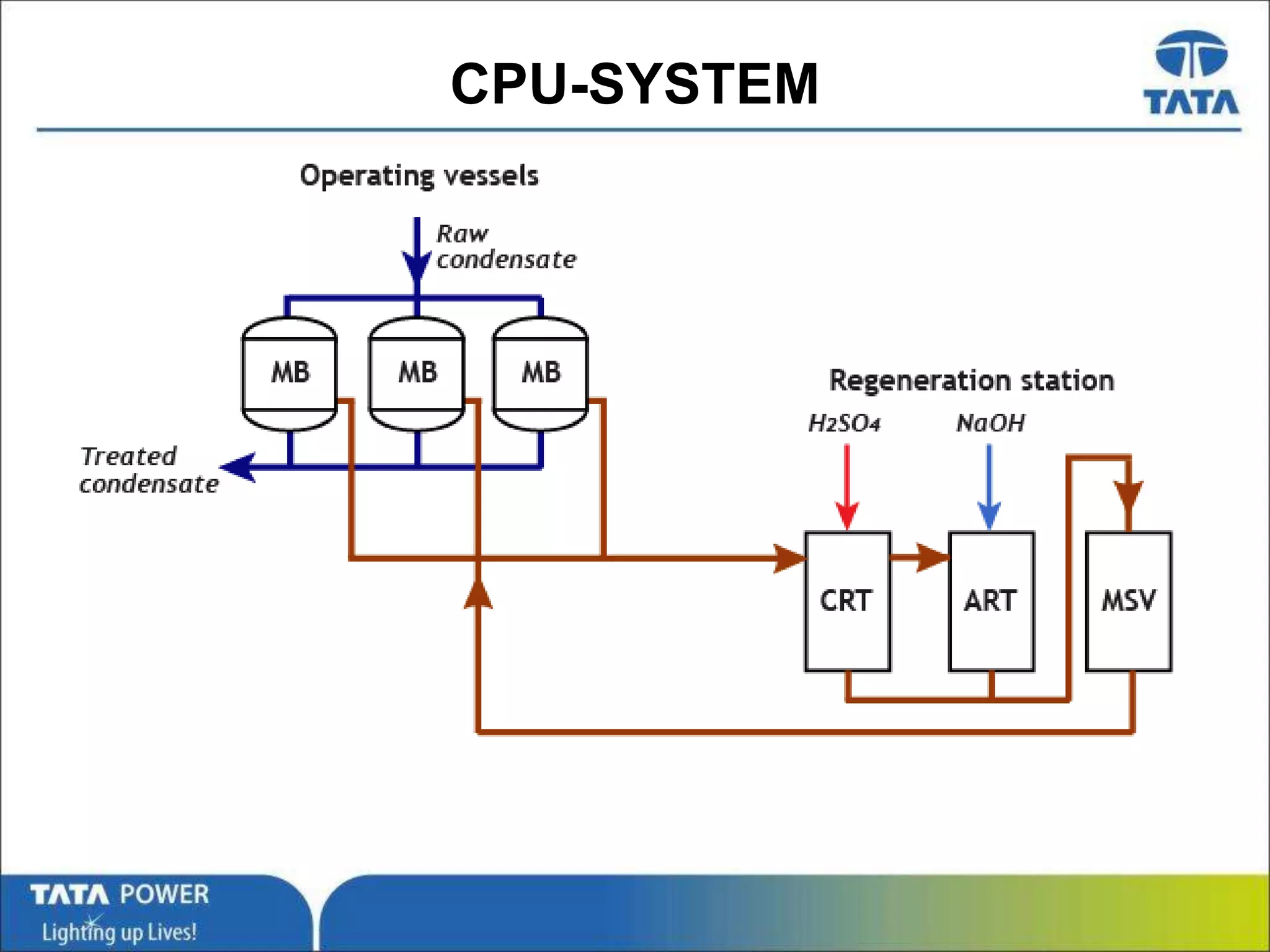

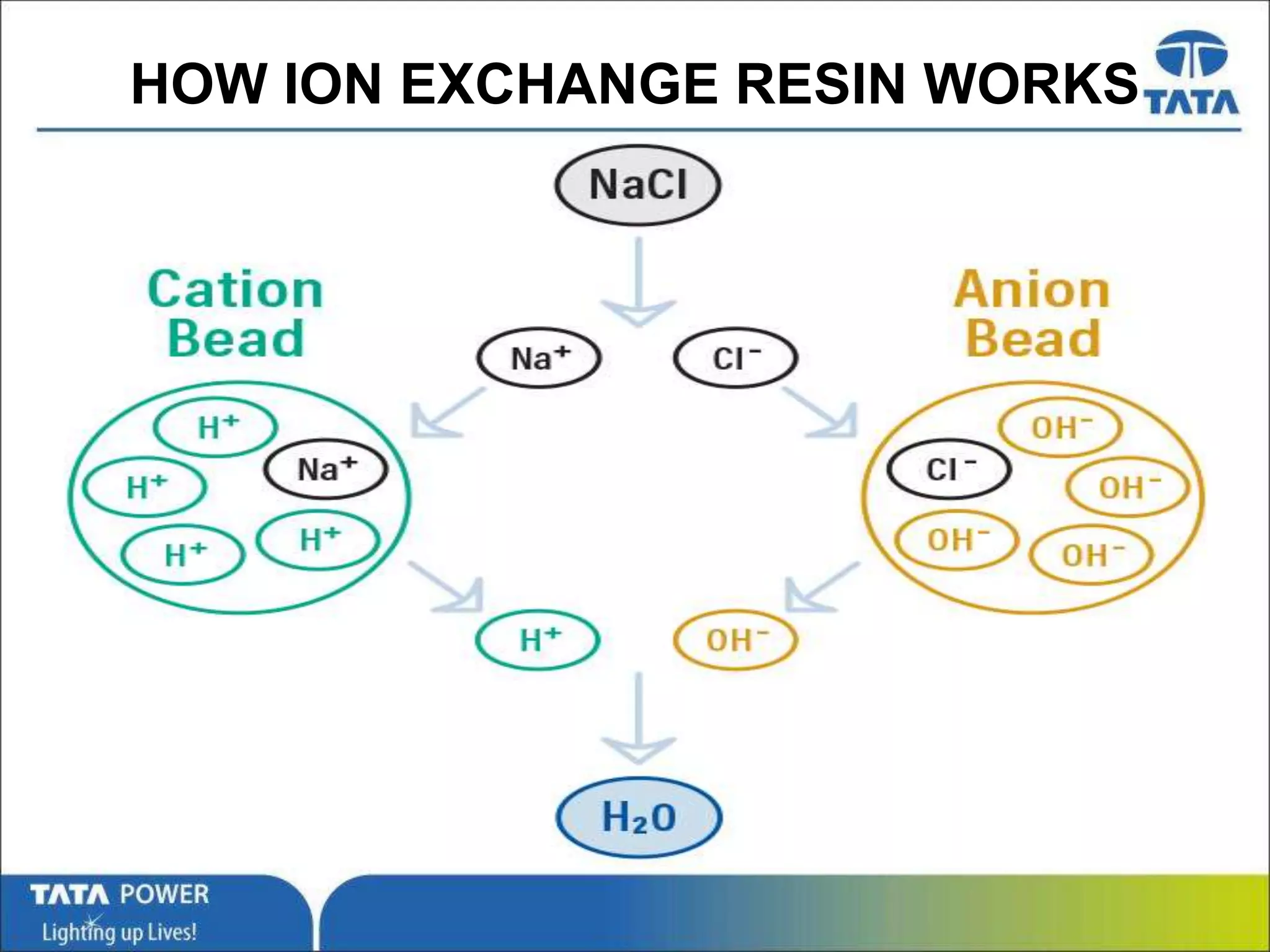

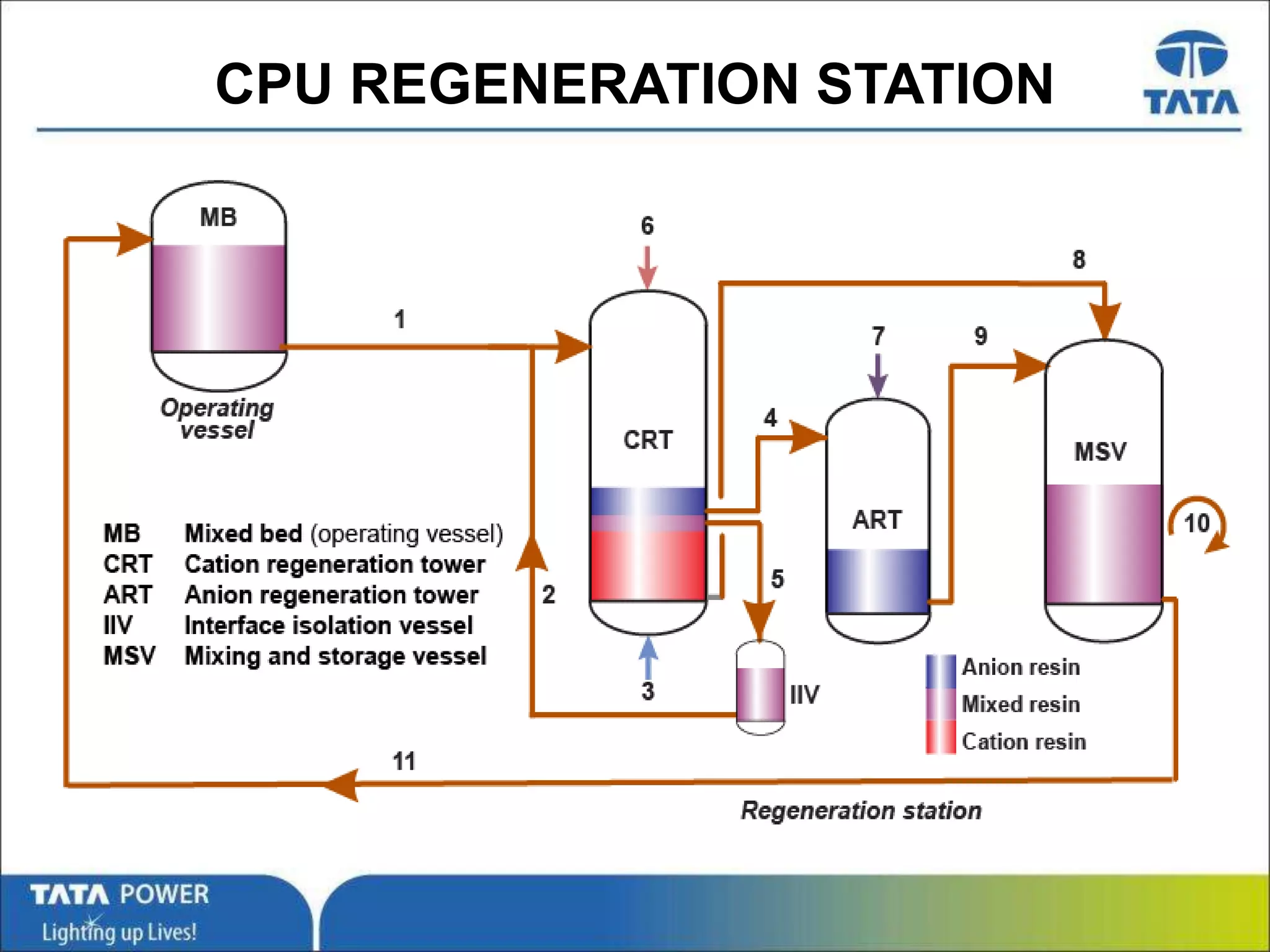

The document discusses a condensate polishing unit (CPU), which is a resin-based ion exchange system that treats boiler feedwater to improve water quality. It removes dissolved and suspended contaminants to make boiler operation more efficient and improve steam quality. The CPU controls corrosion, impurities from makeup water, and condenser leaks. It works by exchanging ions through mixed cation and anion resin beds and regenerating the resins to remove residual ions. Key factors that impact its performance include flow rate, regeneration process, water composition treated, and resin quality. It outlines the CPU design, regeneration steps, operating cycles, and design options used at a particular power plant.

![…Message Box ( Arial, Font size 18 Bold)

CYCLES OF DEEP BED MB

• Hydrogen Cycle

• [RES]-H+ + NH4+ → [RES]-NH4+ + H+

• 7 days (168 Hours)

• Ammonia Cycle

• [RES]-NH4+ + Na+ → [RES]-Na+ + NH4+

• 14 days (336 Hours)](https://image.slidesharecdn.com/cpu-presentation1-170210132104/75/Condensate-Polishing-Unit-CPU-21-2048.jpg)