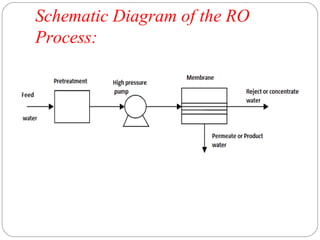

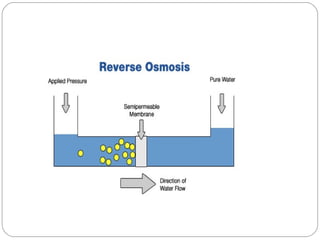

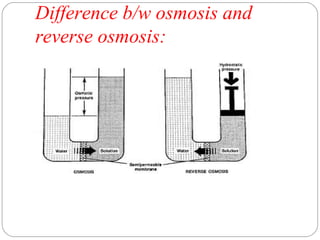

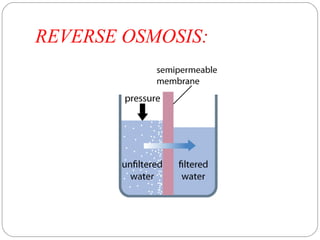

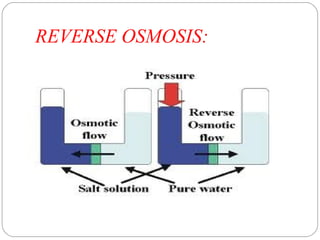

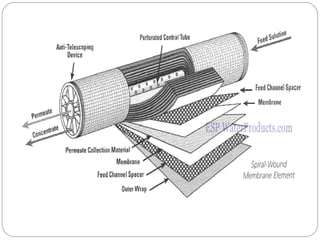

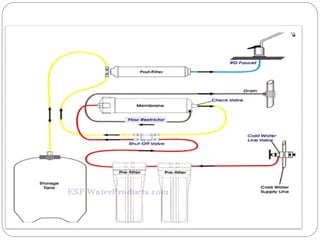

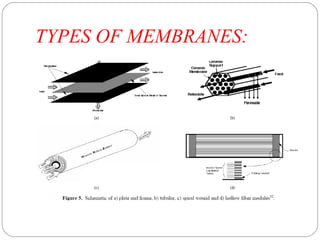

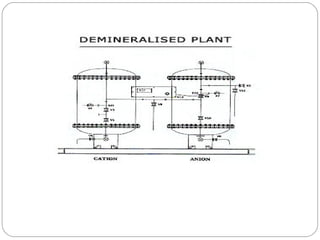

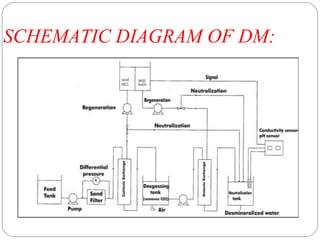

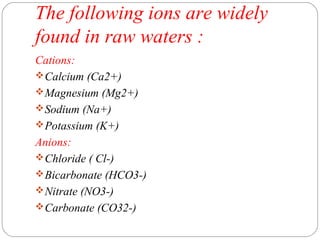

Reverse osmosis uses semi-permeable membranes to purify water by separating dissolved solids. It has various applications in water treatment and is used along with demineralization plants. A reverse osmosis system consists of pre-treatment, high-pressure pumps, membrane systems, and post-treatment. It produces permeate water while concentrating impurities in reject water. Demineralization uses ion exchange resins to remove mineral ions, producing very high purity water. Together, reverse osmosis and demineralization can purify water for various industrial and medical uses.