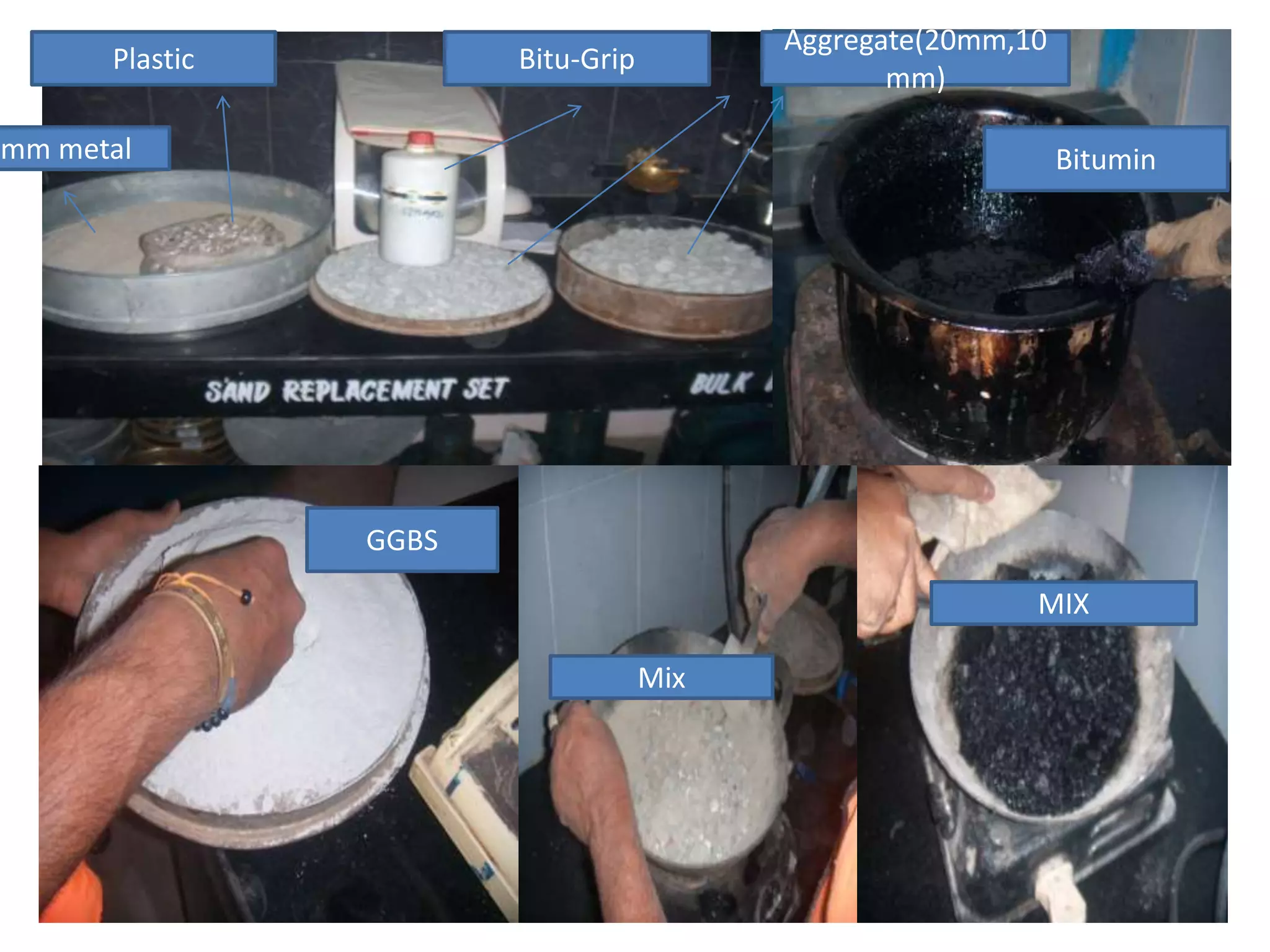

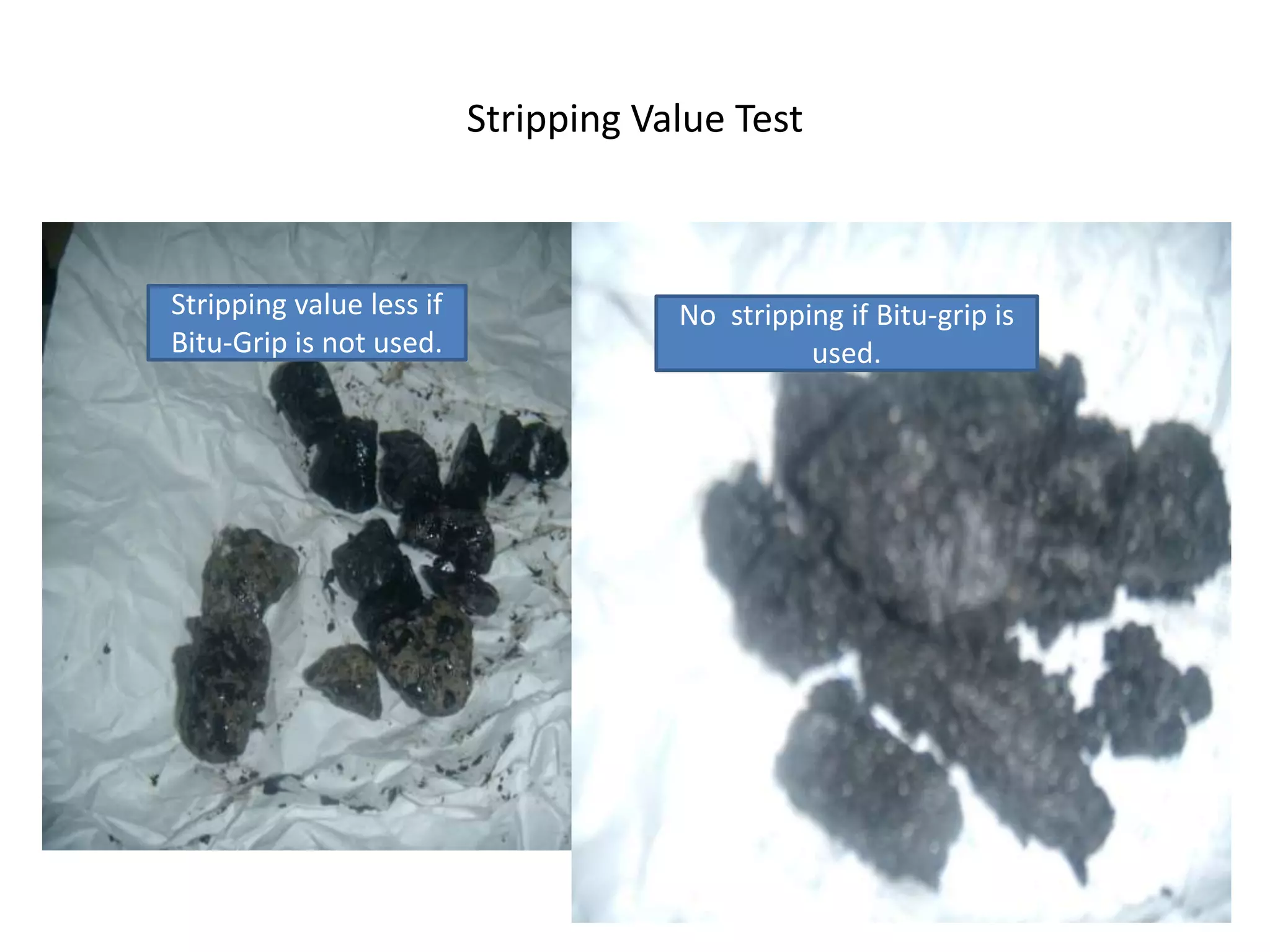

The document discusses bituminous mix design which involves combining aggregates, bitumen, filler materials like cement or GGBS, shredded plastic, and an anti-stripping agent called Bitu-grip. It provides details on the materials used, testing procedures, results of mix designs for different types of mixes like BC, DBM, BM, and MSS. The use of shredded plastic and Bitu-grip can increase bonding between aggregate and bitumen while filler reduces voids and increases strength. GGBS can be used instead of cement, providing cost savings. Use of these additives results in reduced binder and bitumen content.