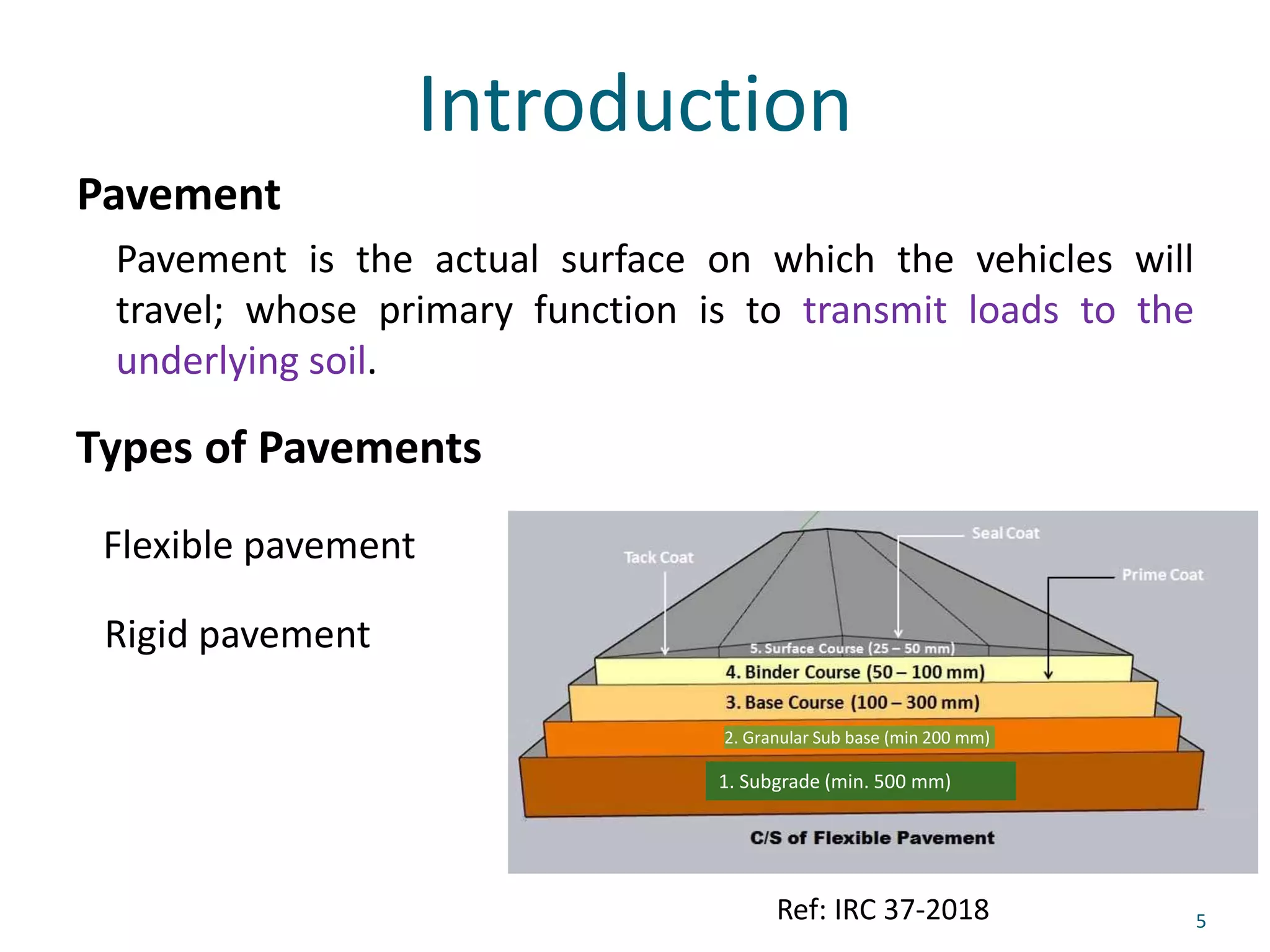

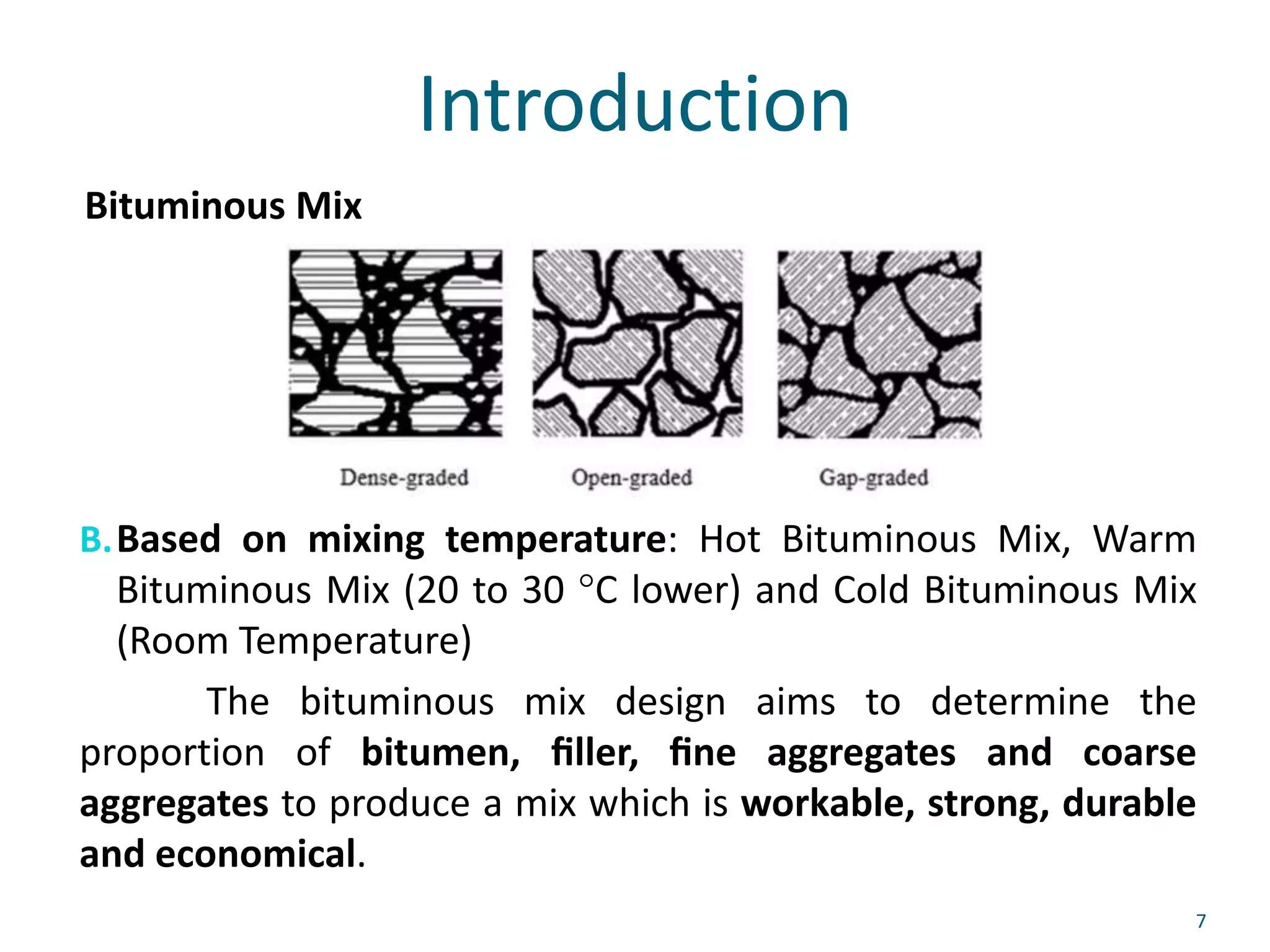

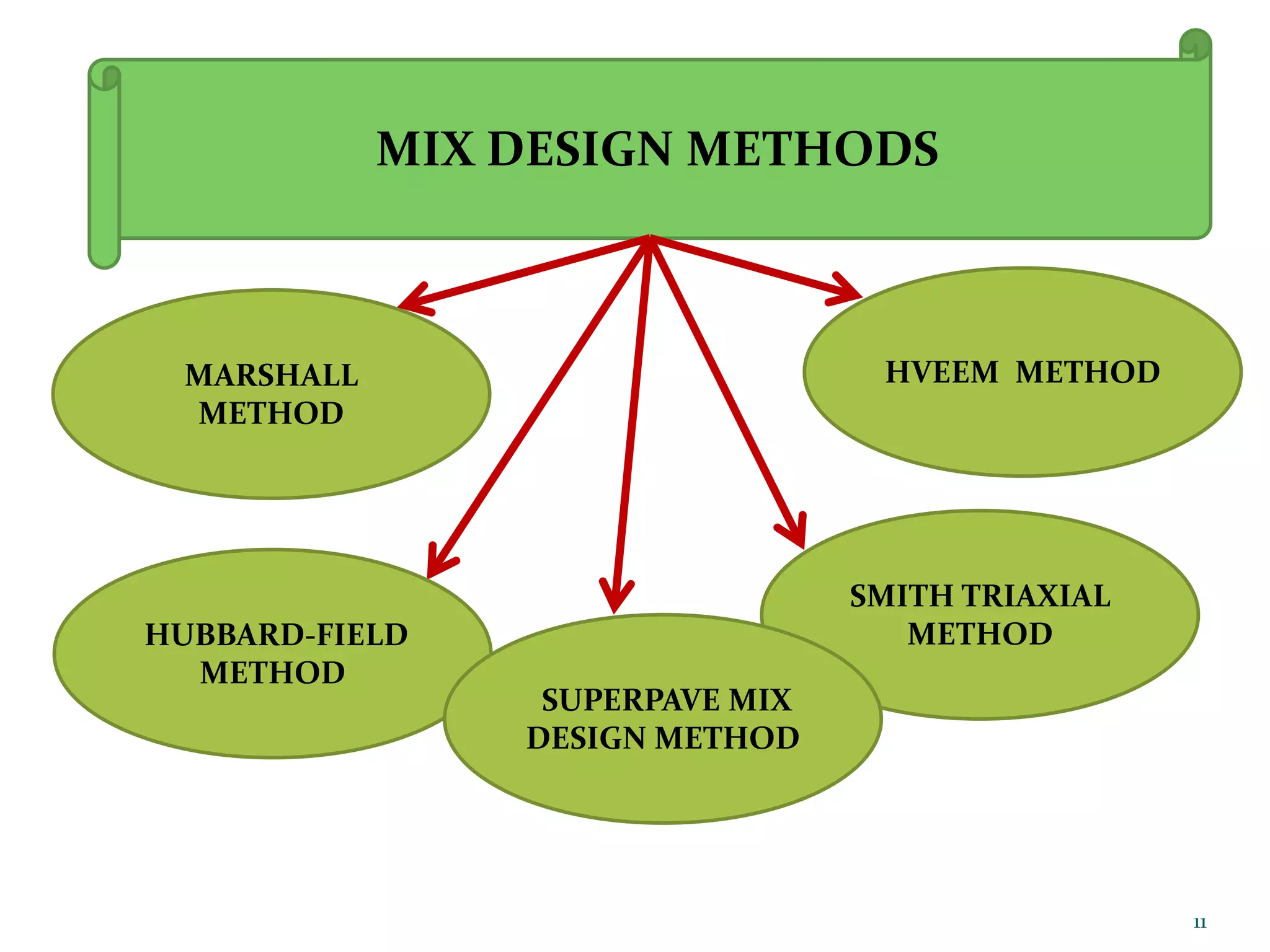

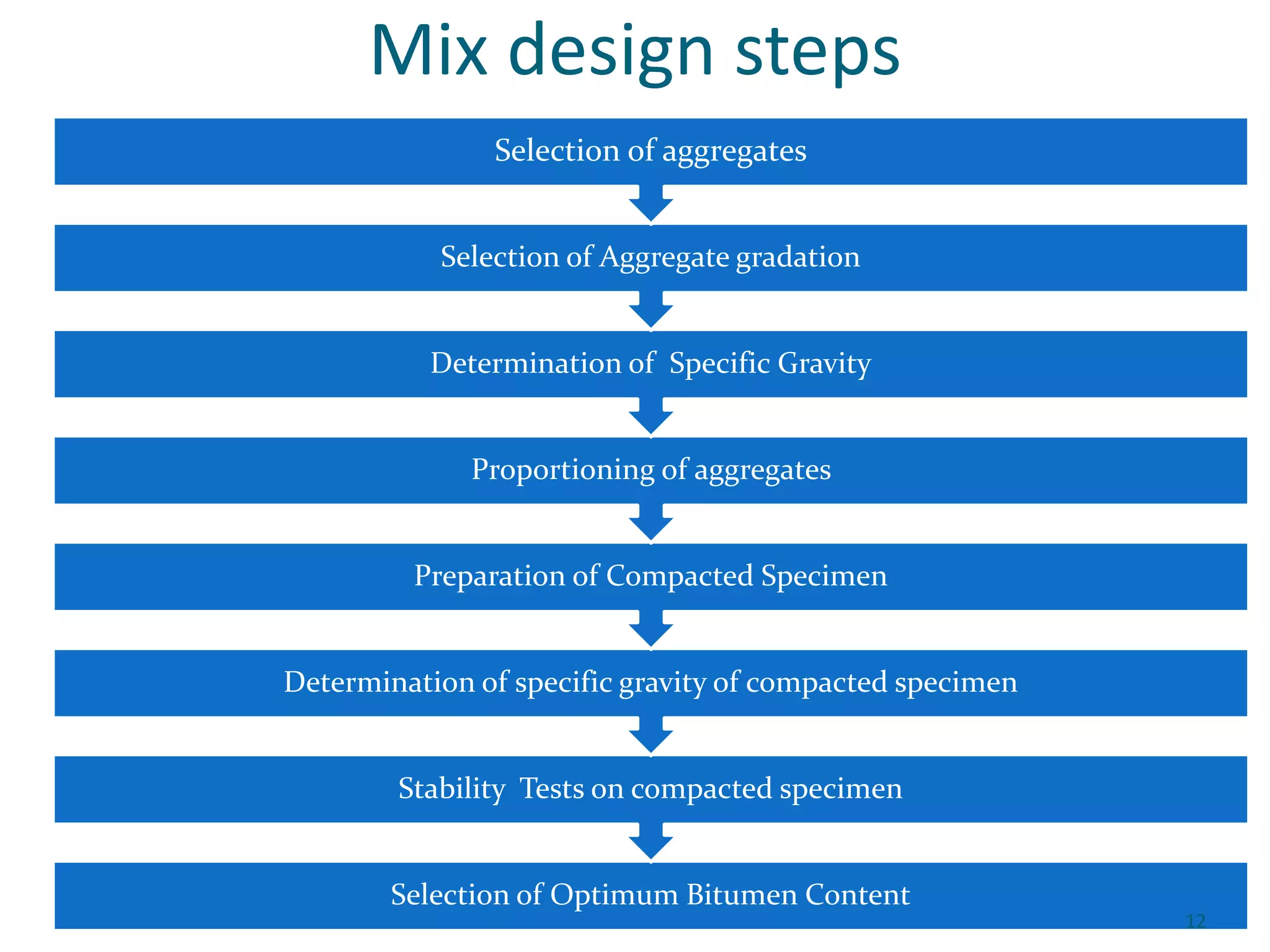

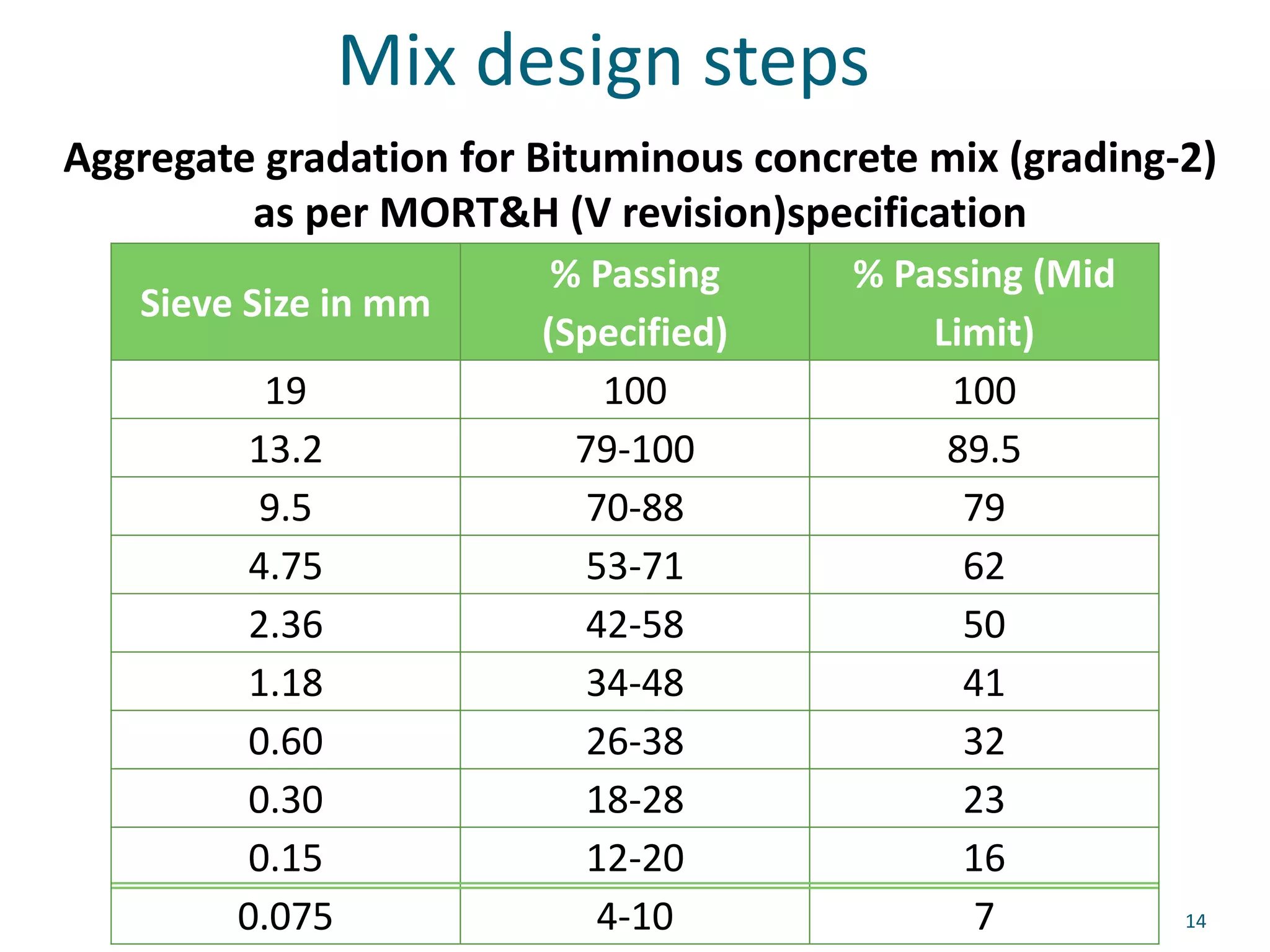

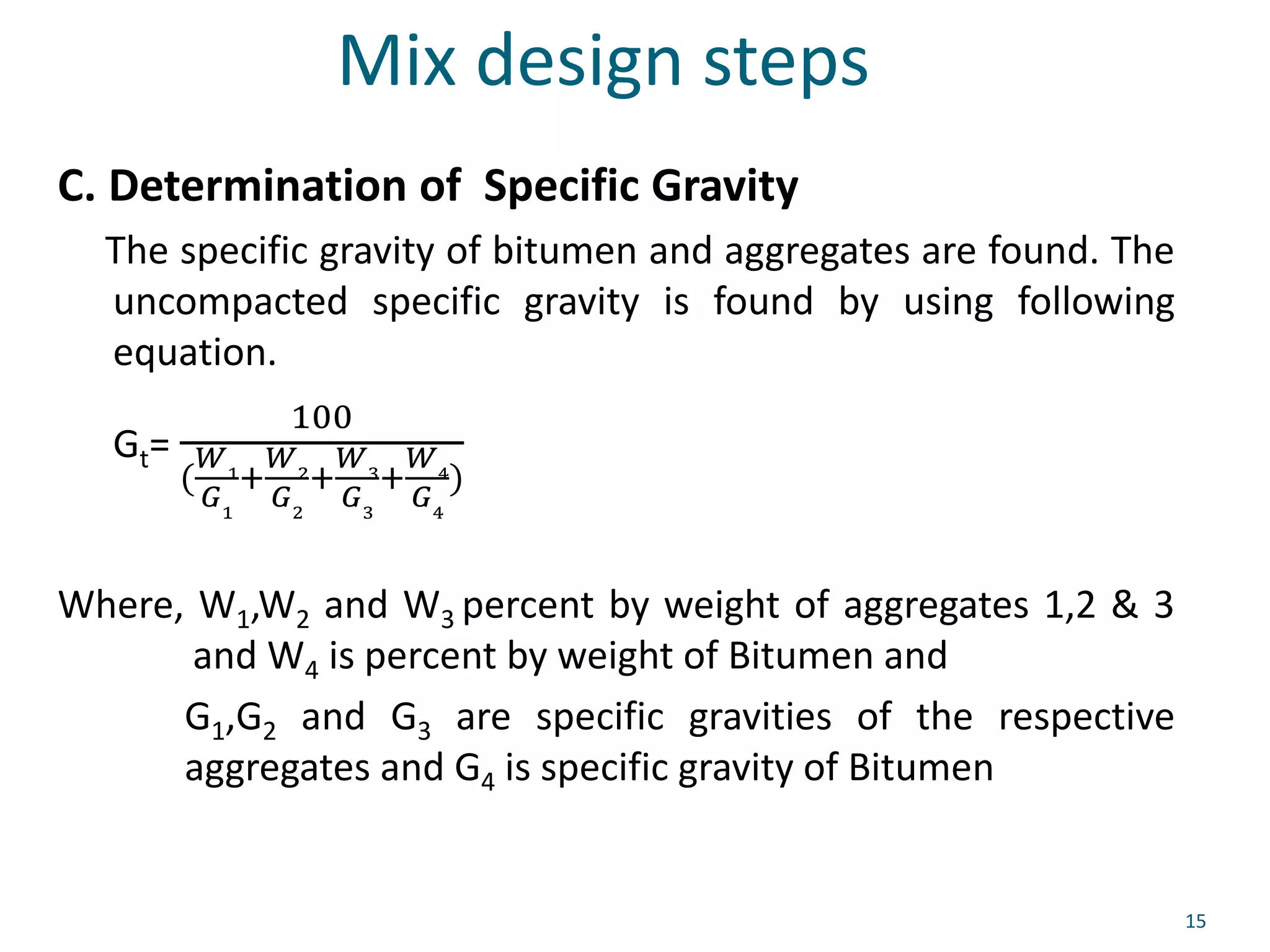

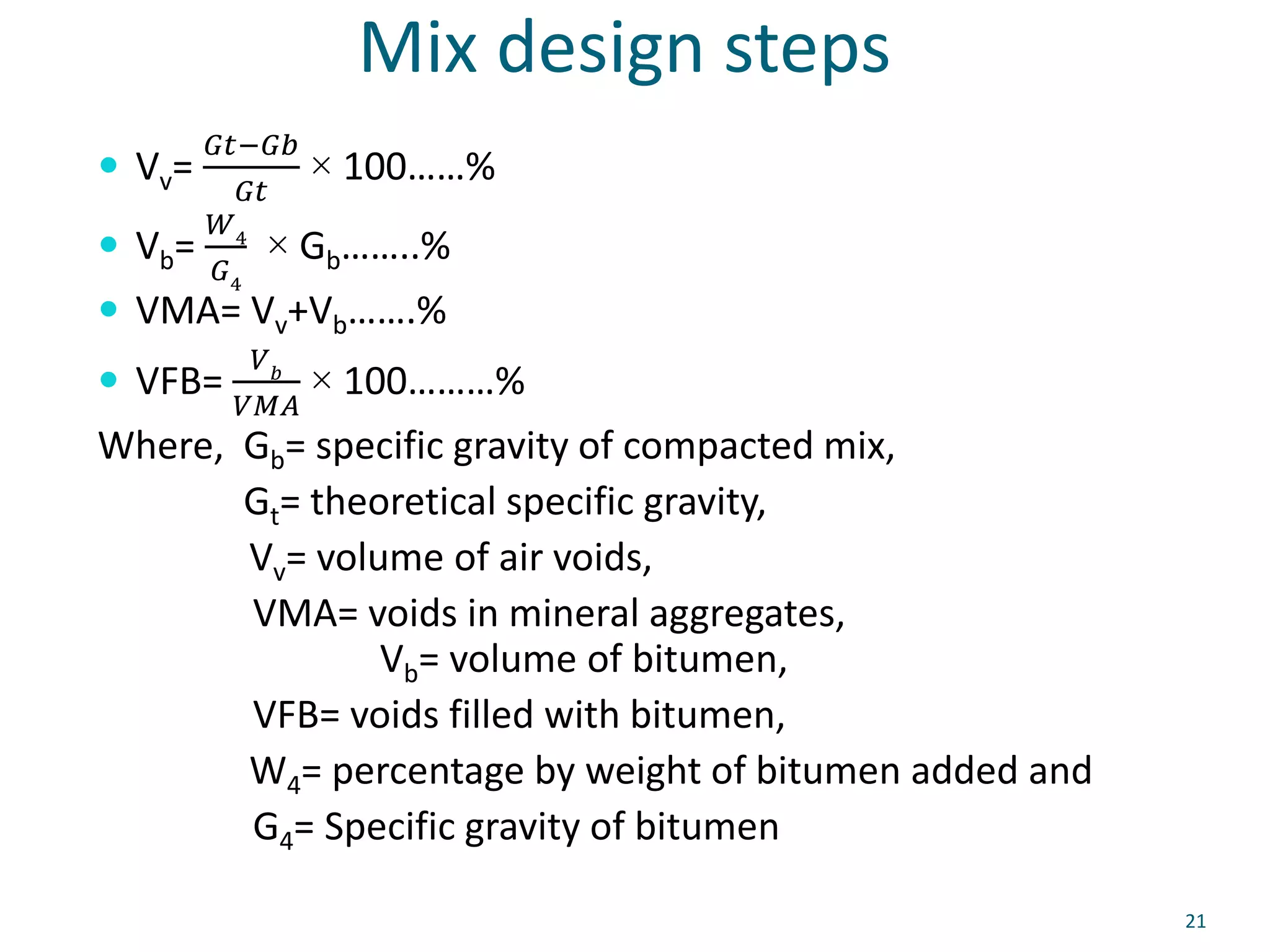

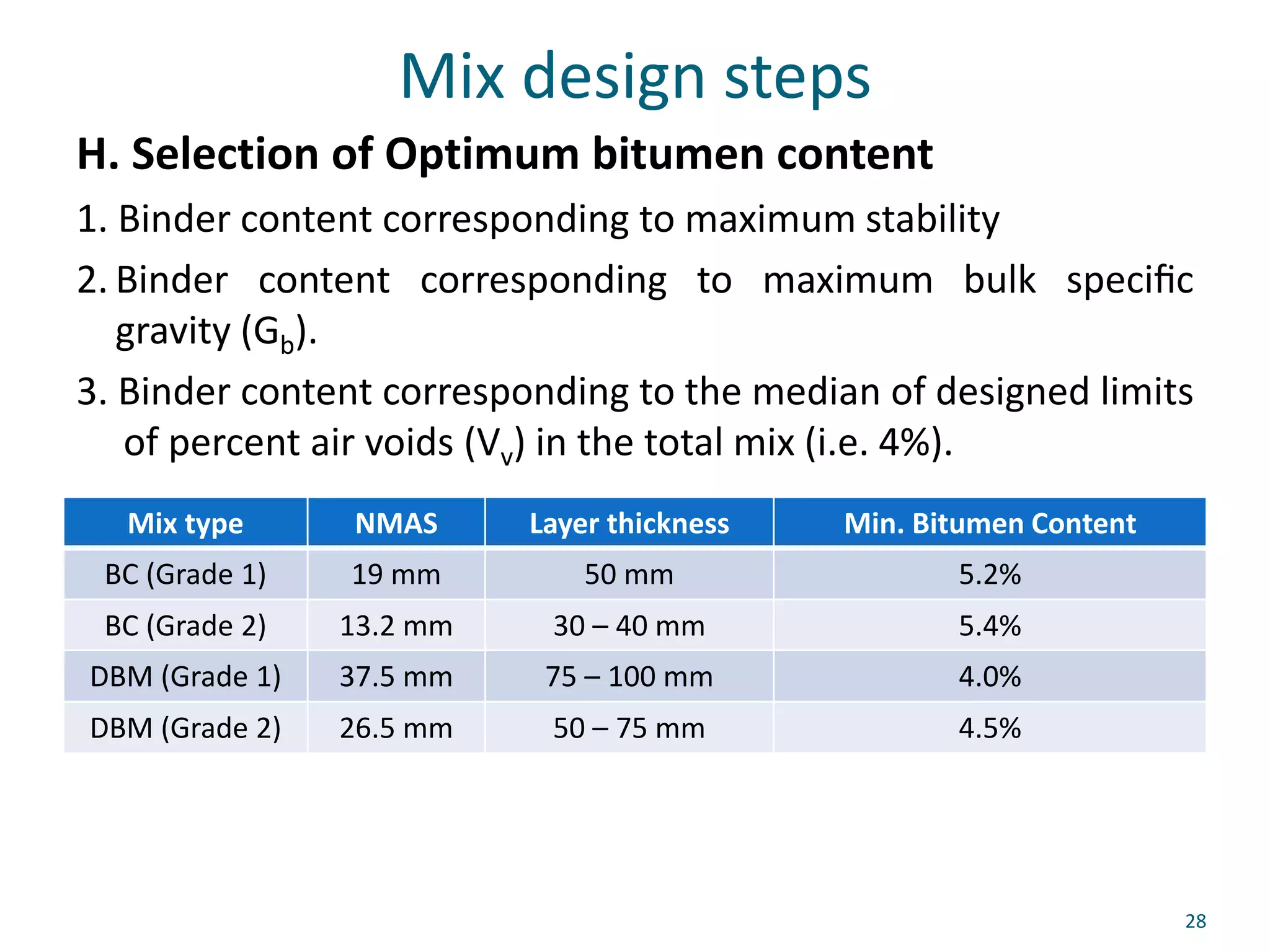

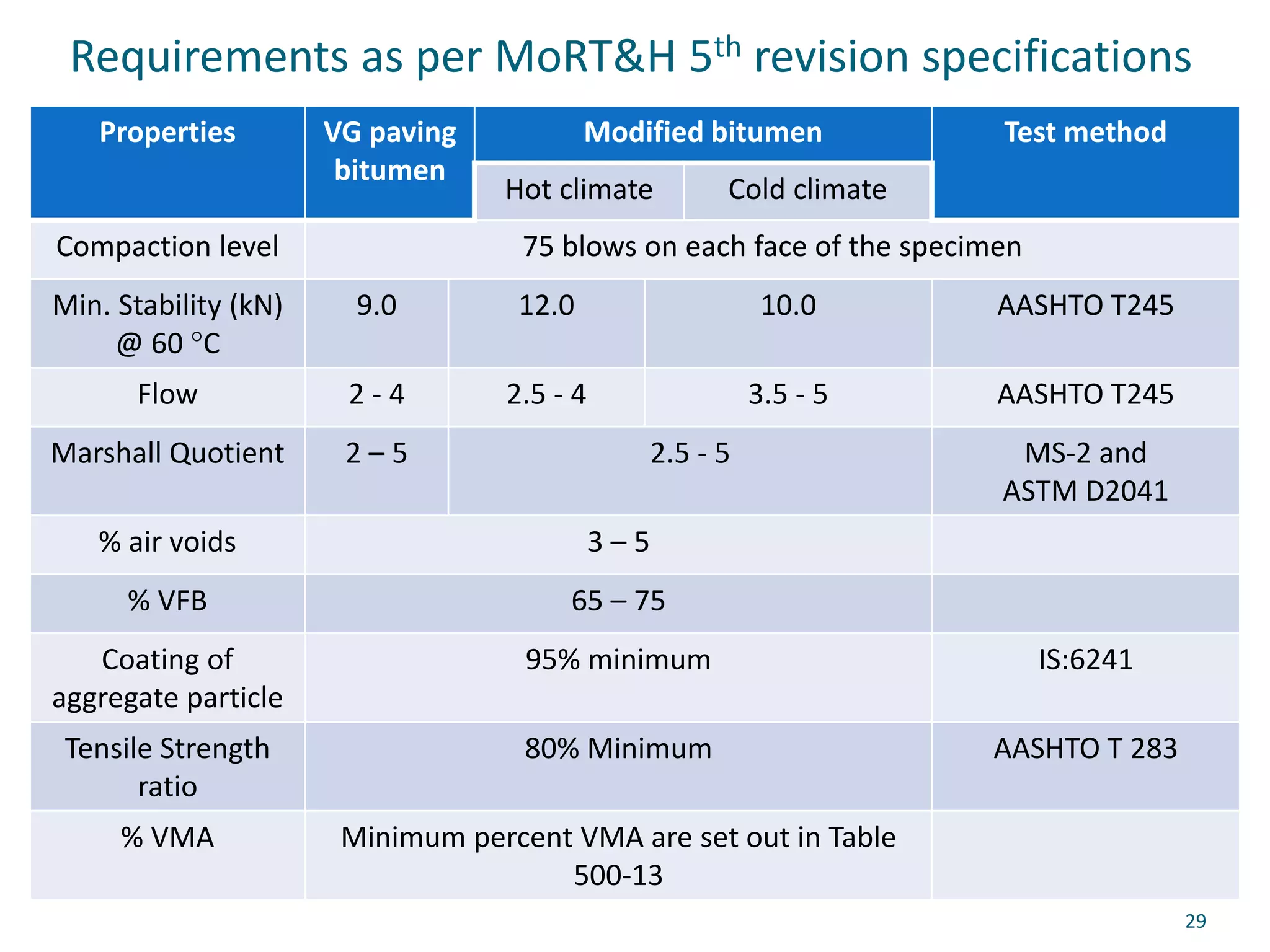

This document provides a profile summary of Dr. Ashik Bellary Amie, an assistant professor at KLS VDIT in Karnataka, India. It lists his qualifications and experience including being a reviewer for several international journals and conferences on transportation engineering topics. It also outlines his educational background and awards received. The document then provides an outline for a presentation on bituminous mix design, covering the need for mix design, desirable mix properties, common design methods, and basic design steps from aggregate selection to determining the optimum binder content. References for further information on mix design are listed at the end.