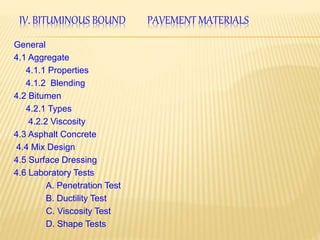

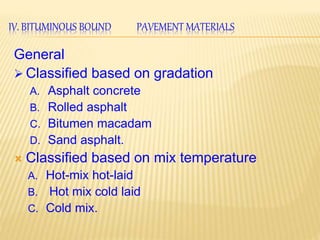

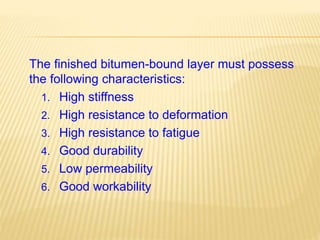

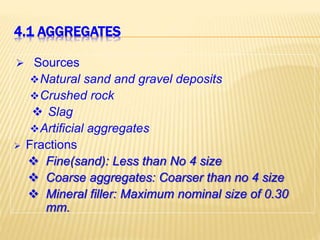

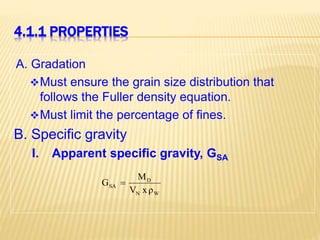

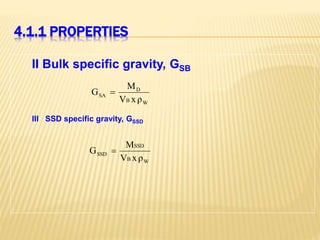

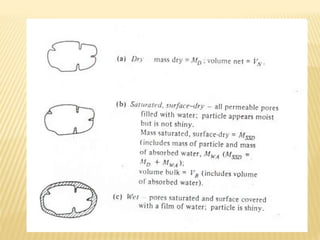

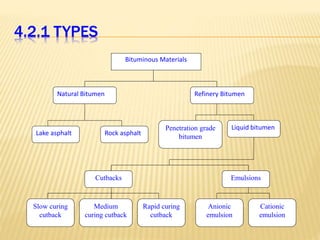

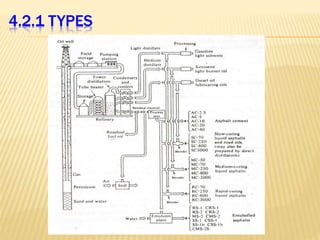

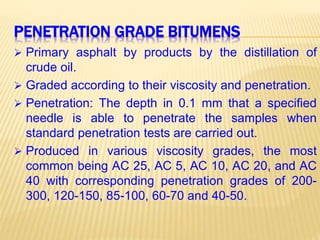

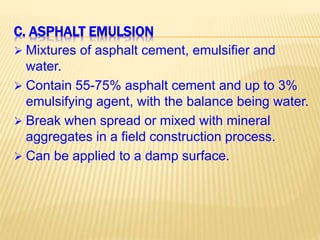

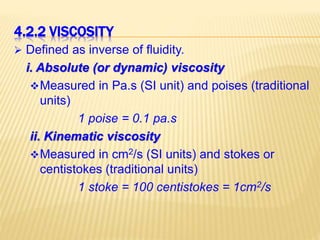

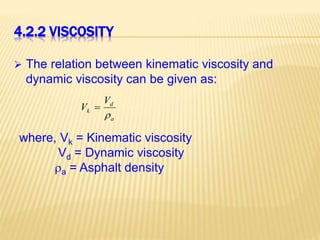

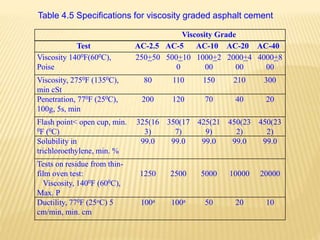

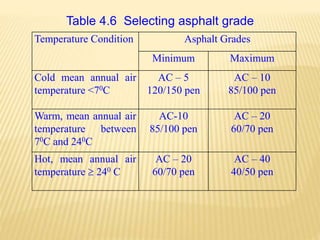

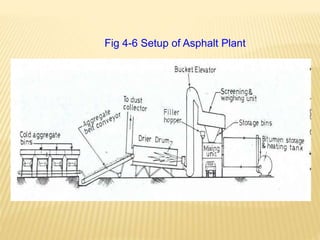

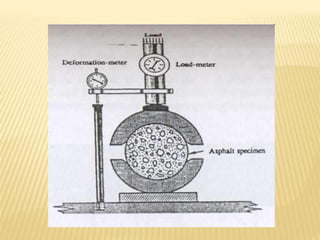

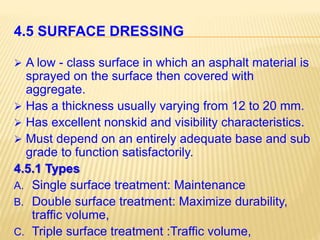

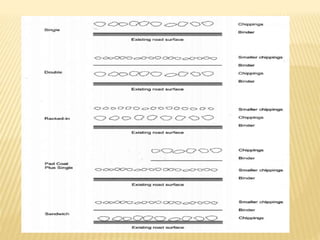

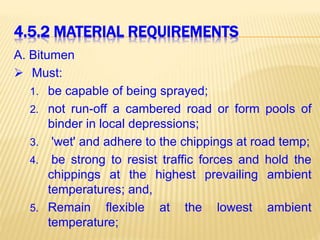

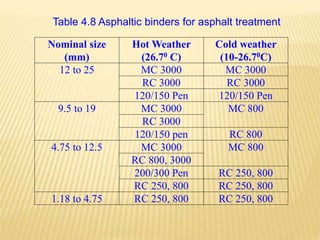

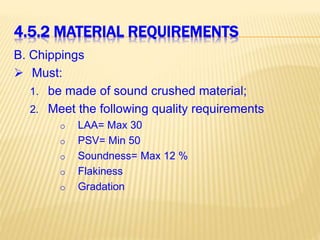

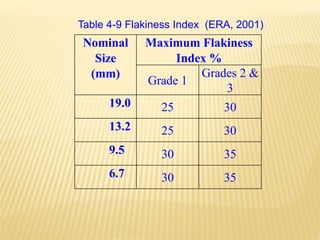

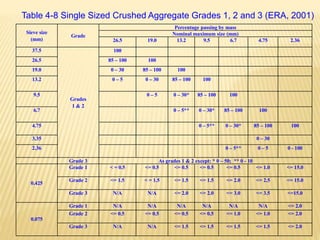

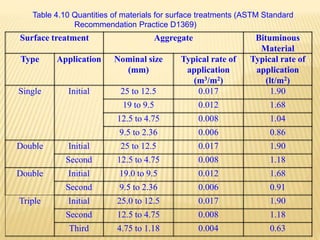

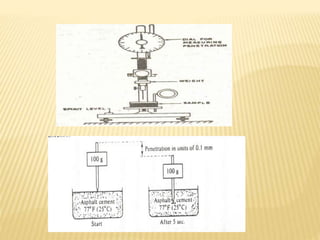

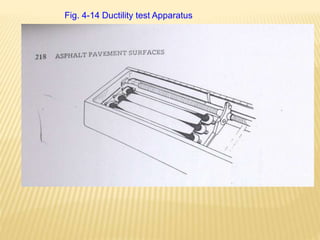

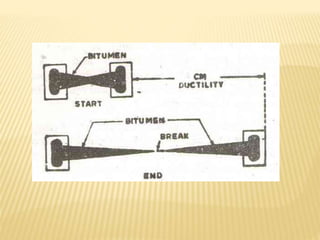

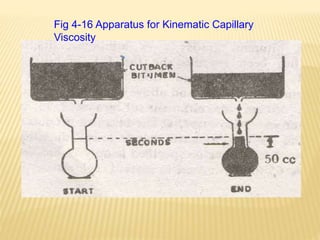

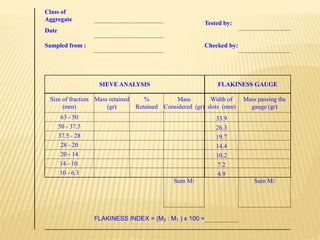

The document discusses materials used in bituminous bound pavements. It describes aggregates, types of bitumen including penetration grade bitumens and cutbacks, and asphalt concrete. It also covers mix design methods like Marshall and Hveem, and construction processes for asphalt concrete pavements and surface dressings. Laboratory tests discussed include penetration, ductility, viscosity, and aggregate shape tests.