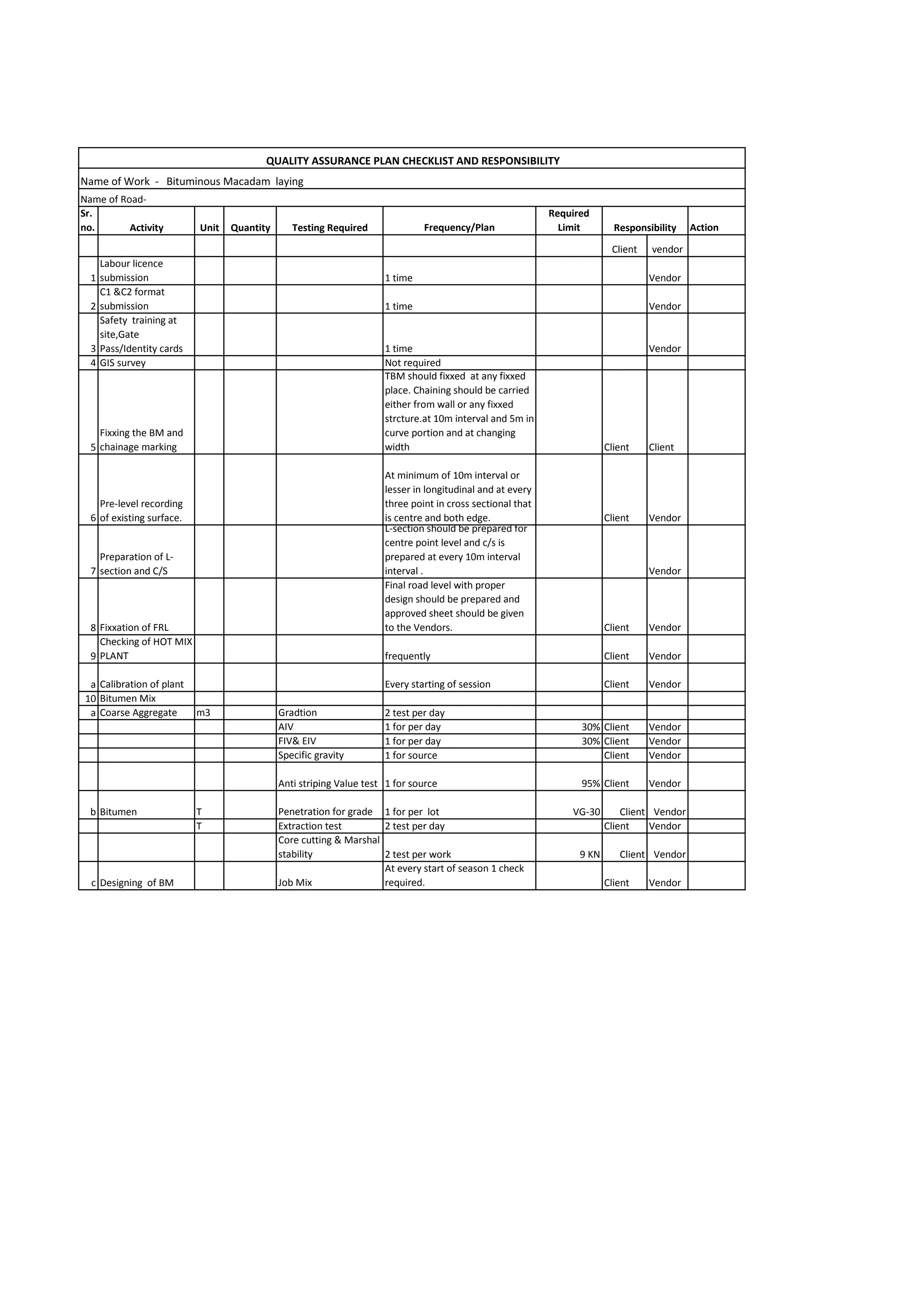

The document outlines a quality assurance plan checklist and responsibilities for road construction and repair works. It details 13 activities including labour licensing, safety training, pre-construction surveys, material testing, construction processes, quality checks, and payment procedures. Responsibilities are assigned to either the vendor, client, or both for ensuring materials and works meet required specifications and timelines at each stage of the project.