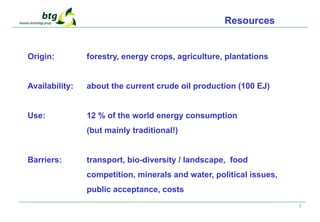

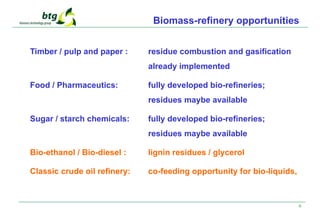

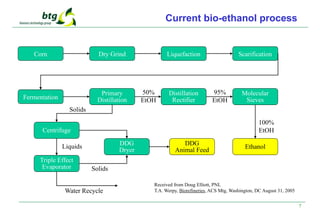

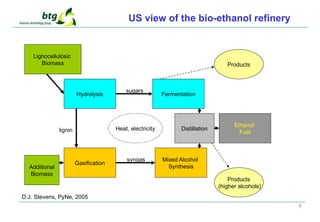

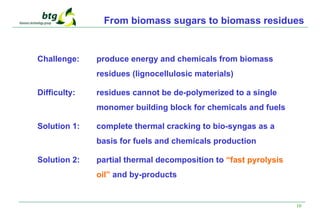

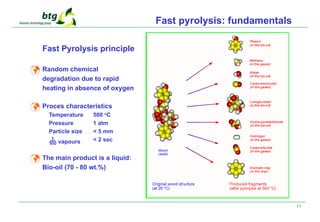

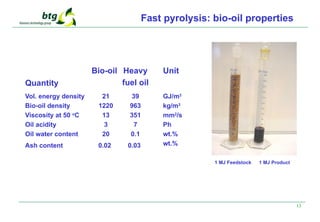

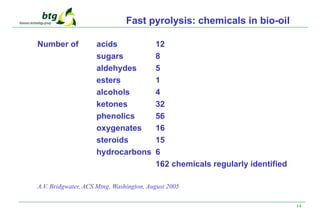

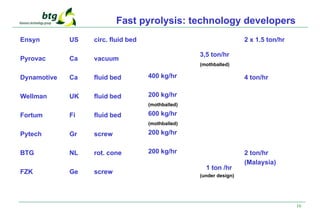

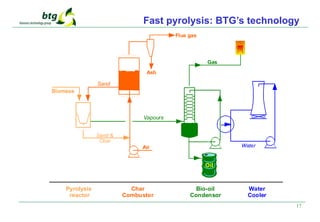

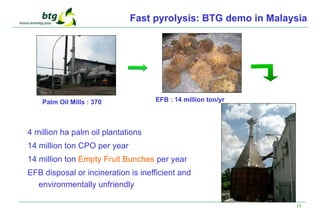

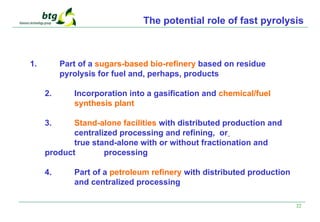

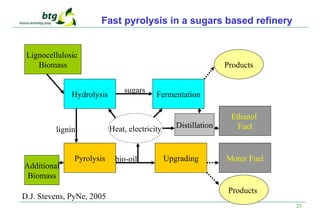

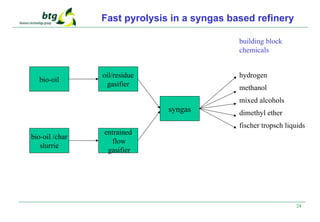

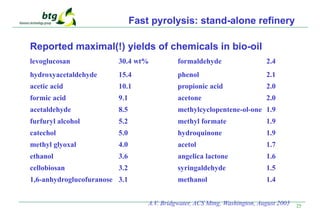

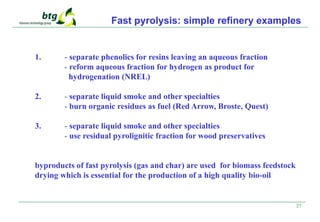

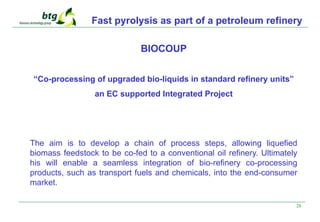

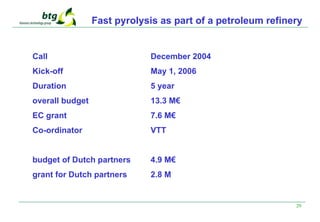

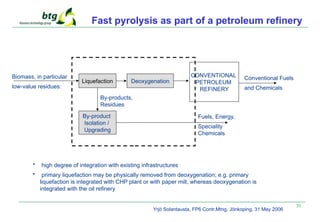

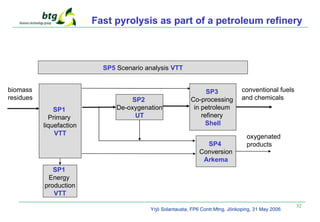

The document discusses the role of fast pyrolysis in biorefineries, emphasizing its potential for converting biomass into valuable liquids and chemicals. It outlines the current state of biomass-based industries, the definition and opportunities of biorefineries, and the processes involved in fast pyrolysis. Additionally, it highlights the challenges and advantages of integrating fast pyrolysis into existing industrial infrastructures and its applications in energy production and chemical synthesis.