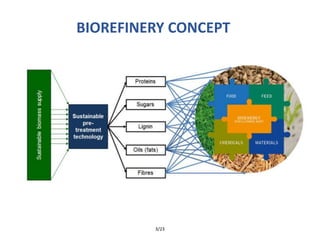

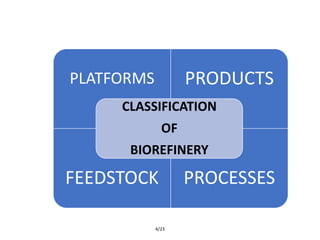

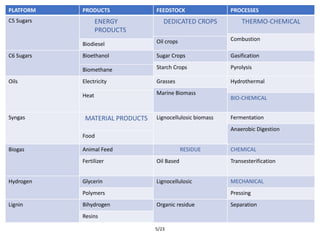

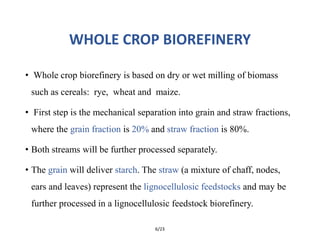

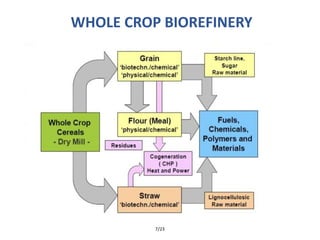

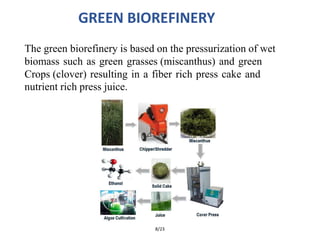

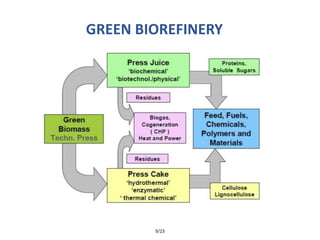

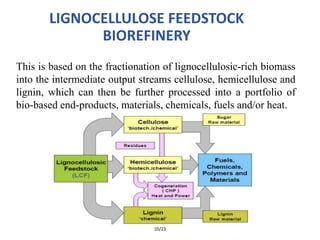

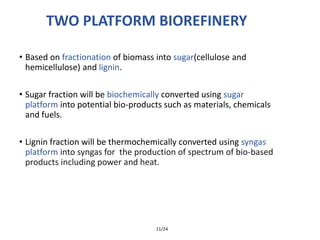

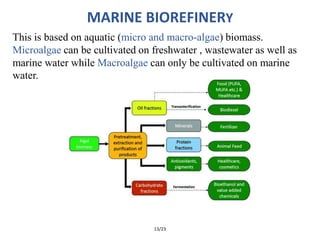

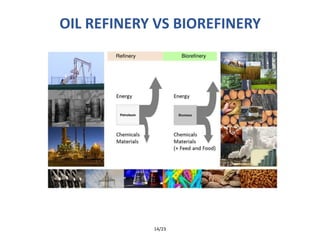

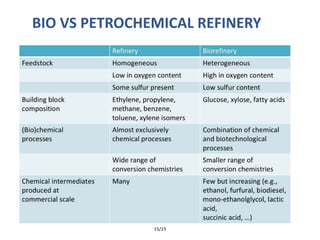

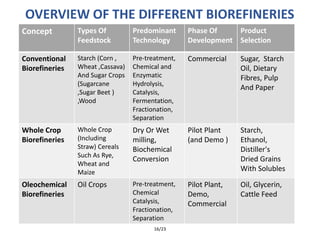

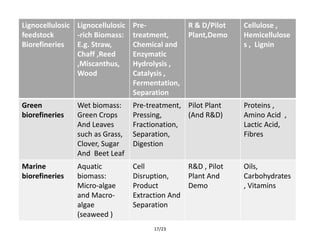

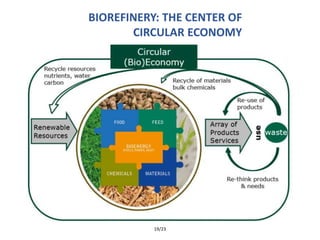

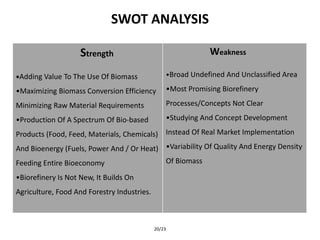

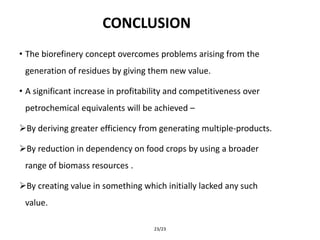

This document discusses different types of biorefineries. A biorefinery integrates processes and equipment to produce fuels, power, and chemicals from biomass. Key types discussed include whole crop biorefineries that process grains and straw, lignocellulosic biorefineries that process materials like straw, green biorefineries that process wet biomass, and marine biorefineries that process algae. The biorefinery concept aims to add value to biomass use and maximize conversion efficiency to produce a variety of biobased products in a more sustainable way than petrochemical approaches.