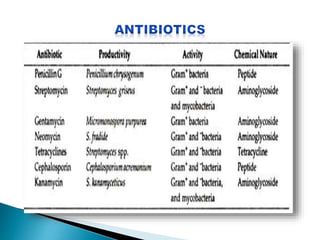

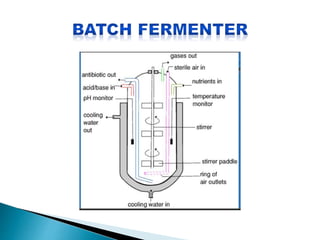

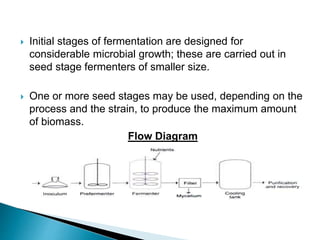

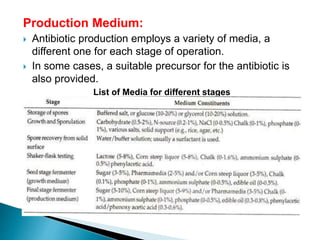

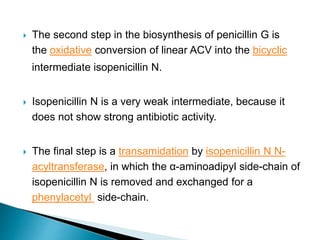

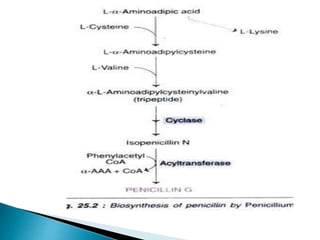

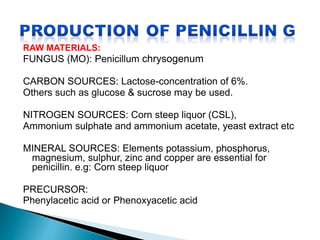

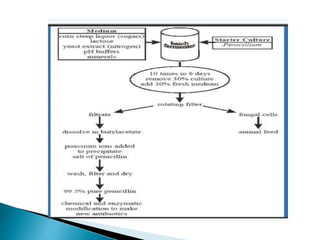

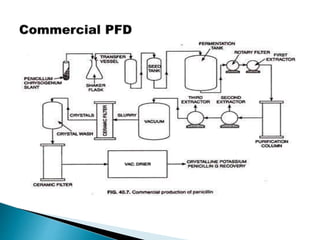

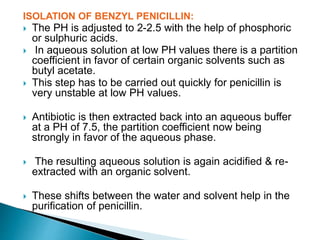

This document provides an overview of the commercial production of antibiotics and penicillin-G. It discusses the discovery of antibiotics and penicillin. The production process involves growing Penicillium chrysogenum fungus in a fermenter using nutrients like lactose as a carbon source. Downstream processing separates the cells and purifies the penicillin product. Key steps include adjusting the pH to extract the penicillin into an organic solvent, then back into aqueous solution for further purification.