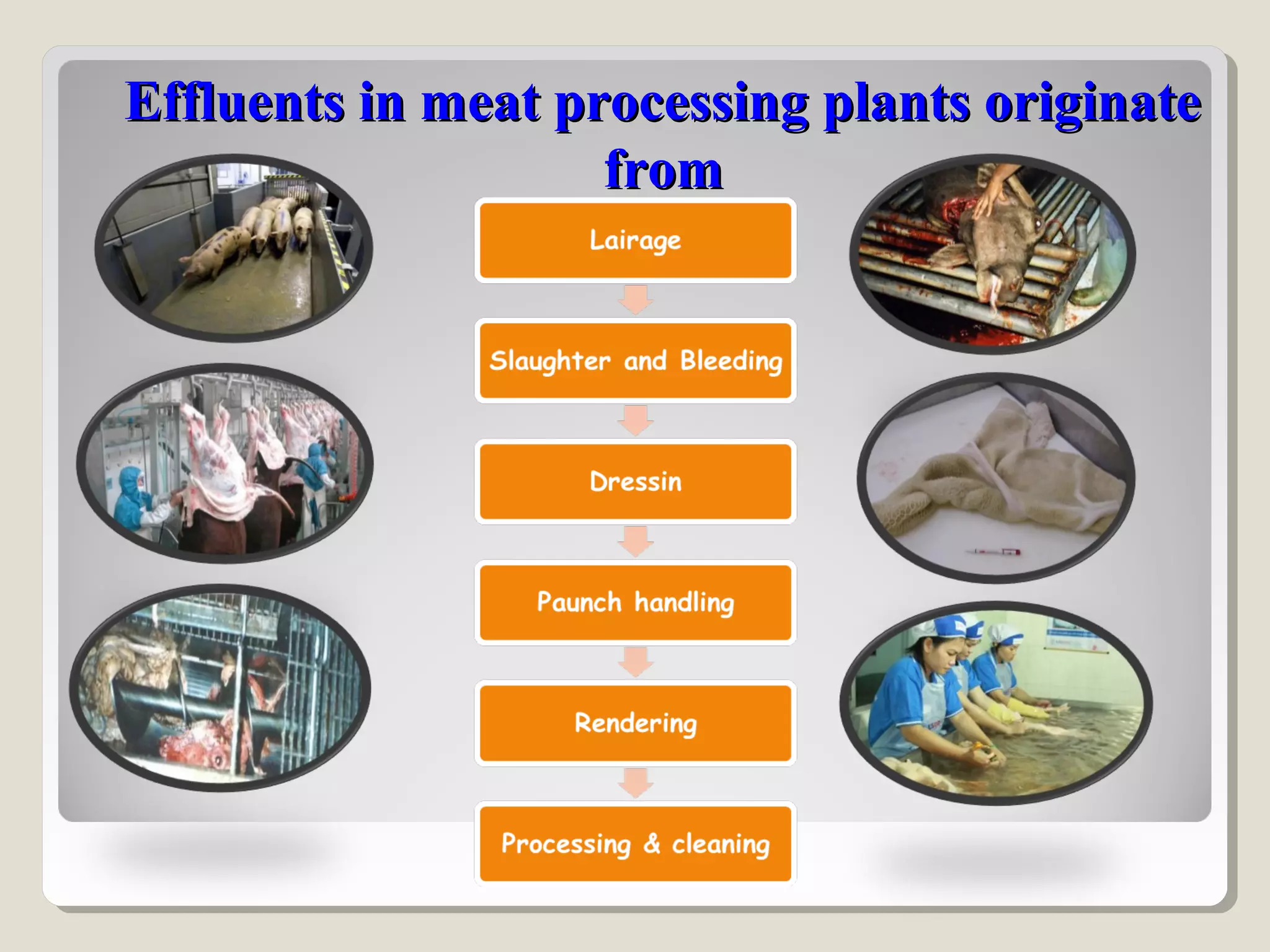

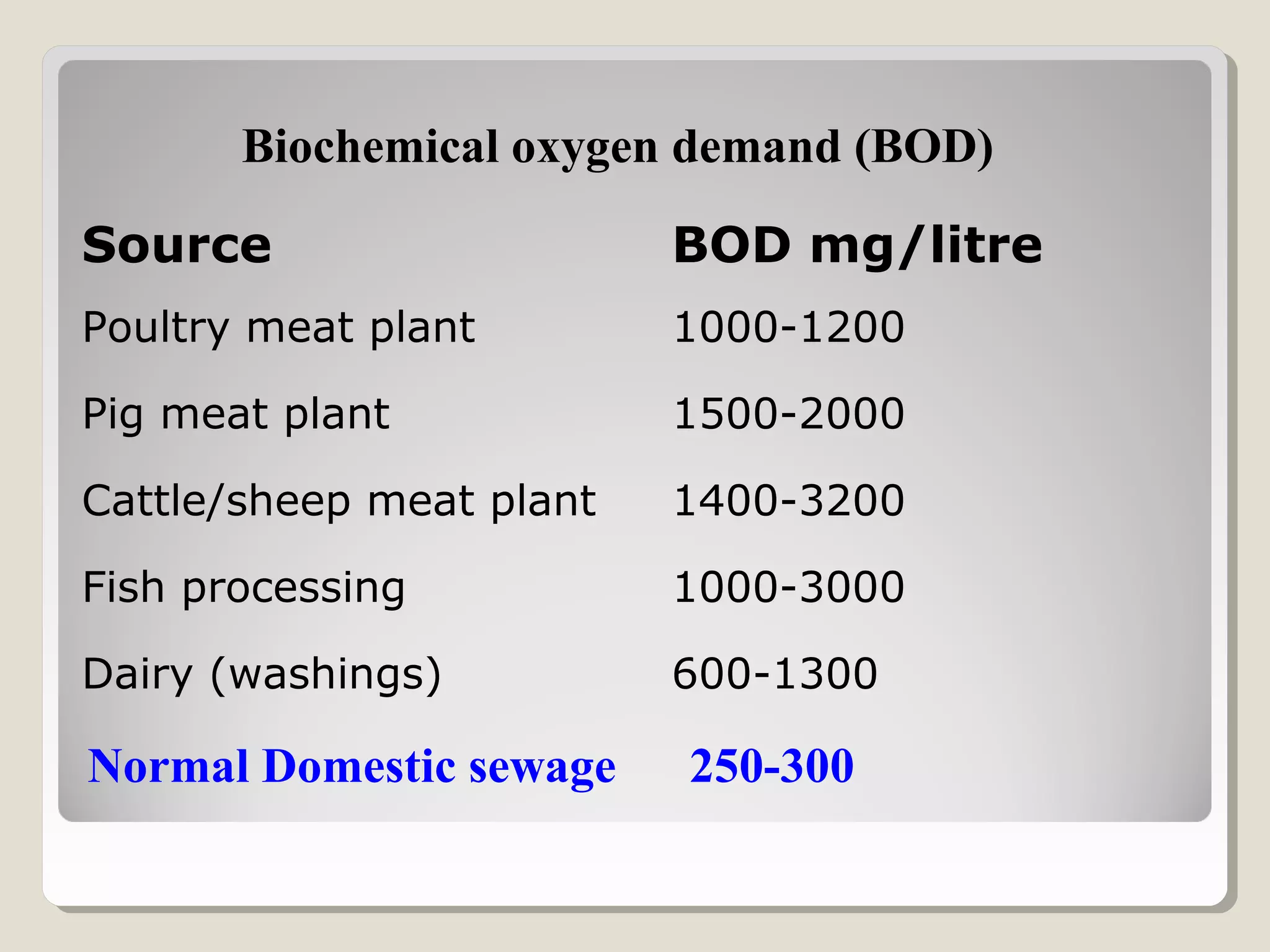

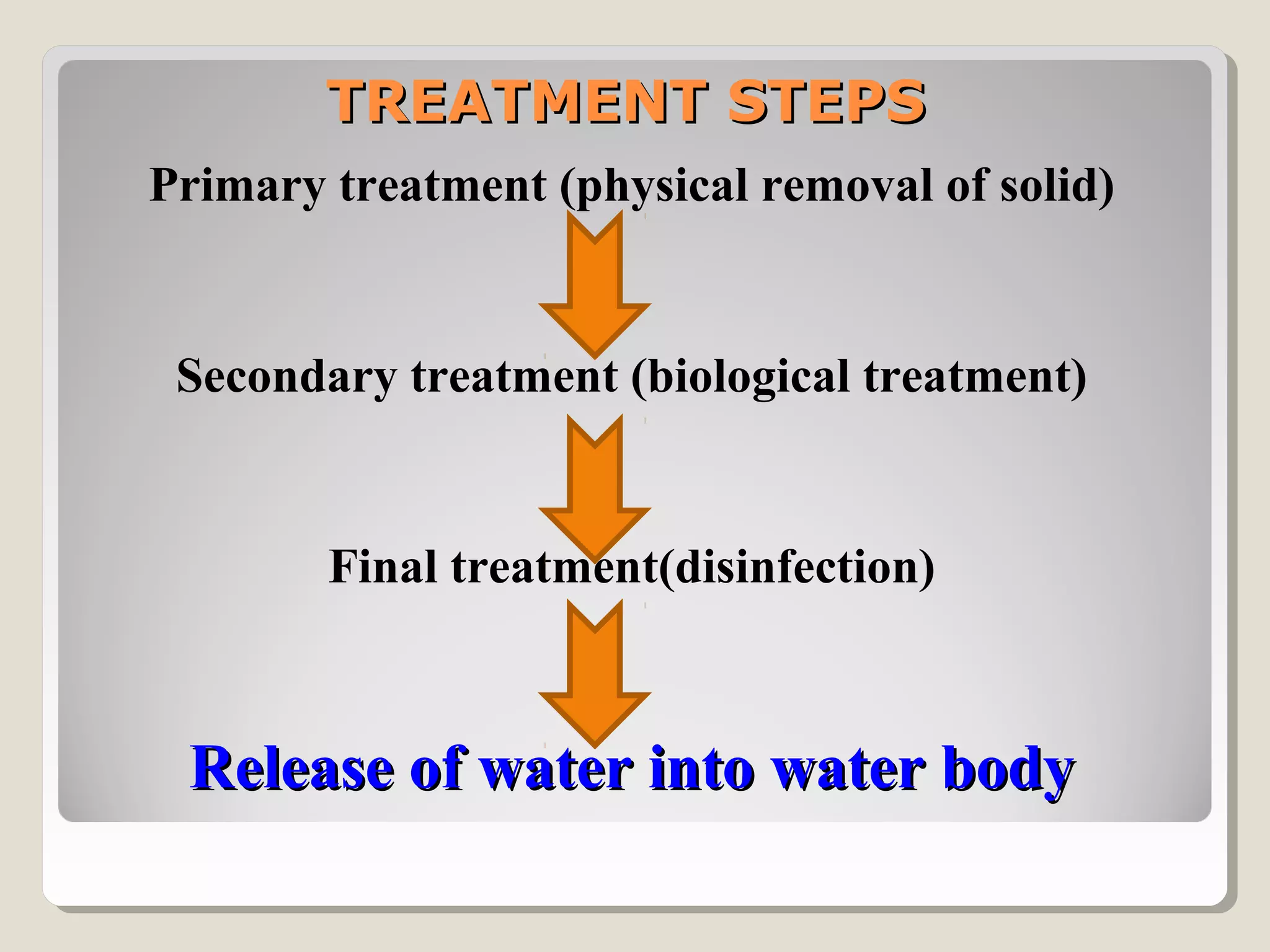

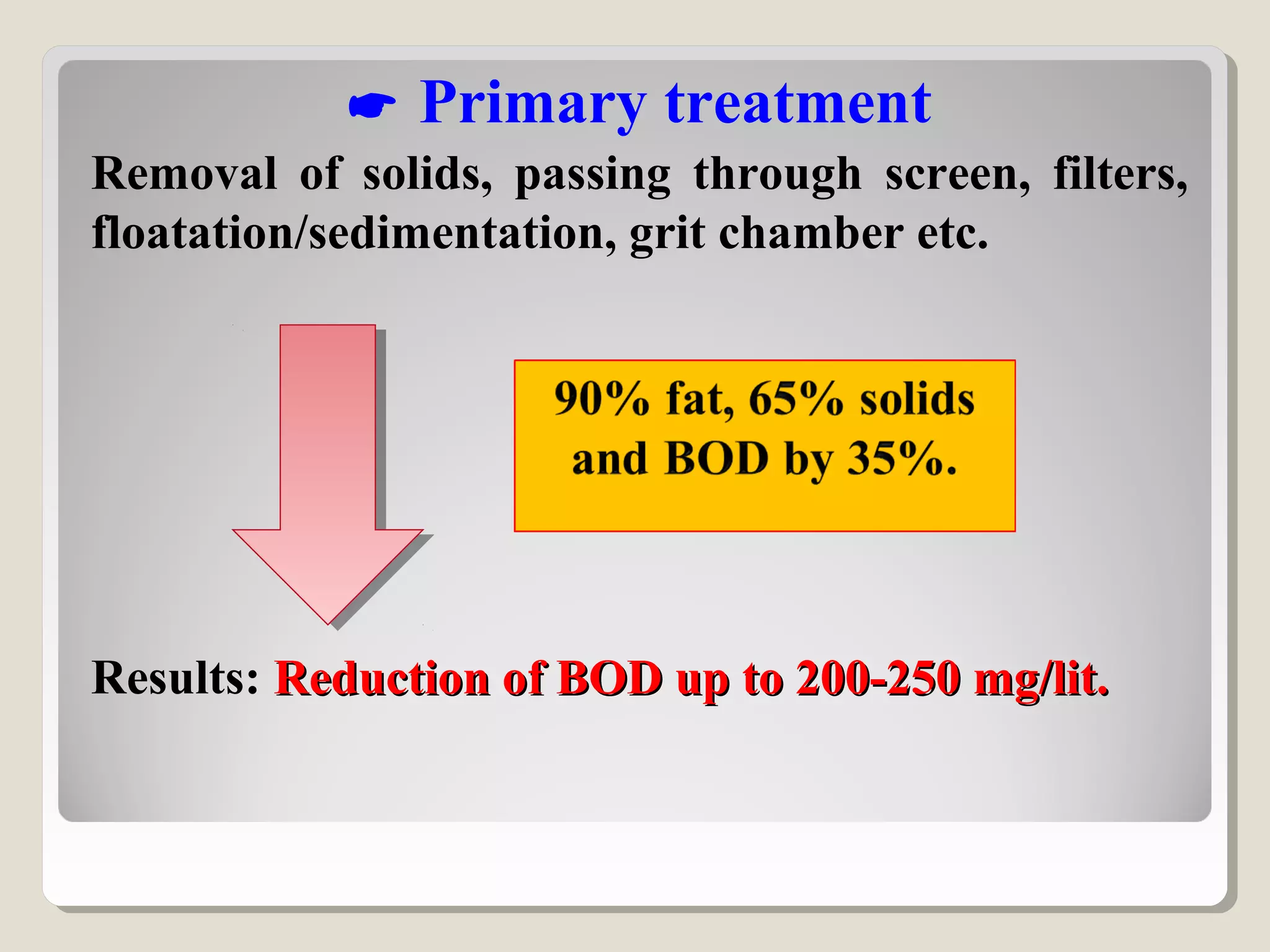

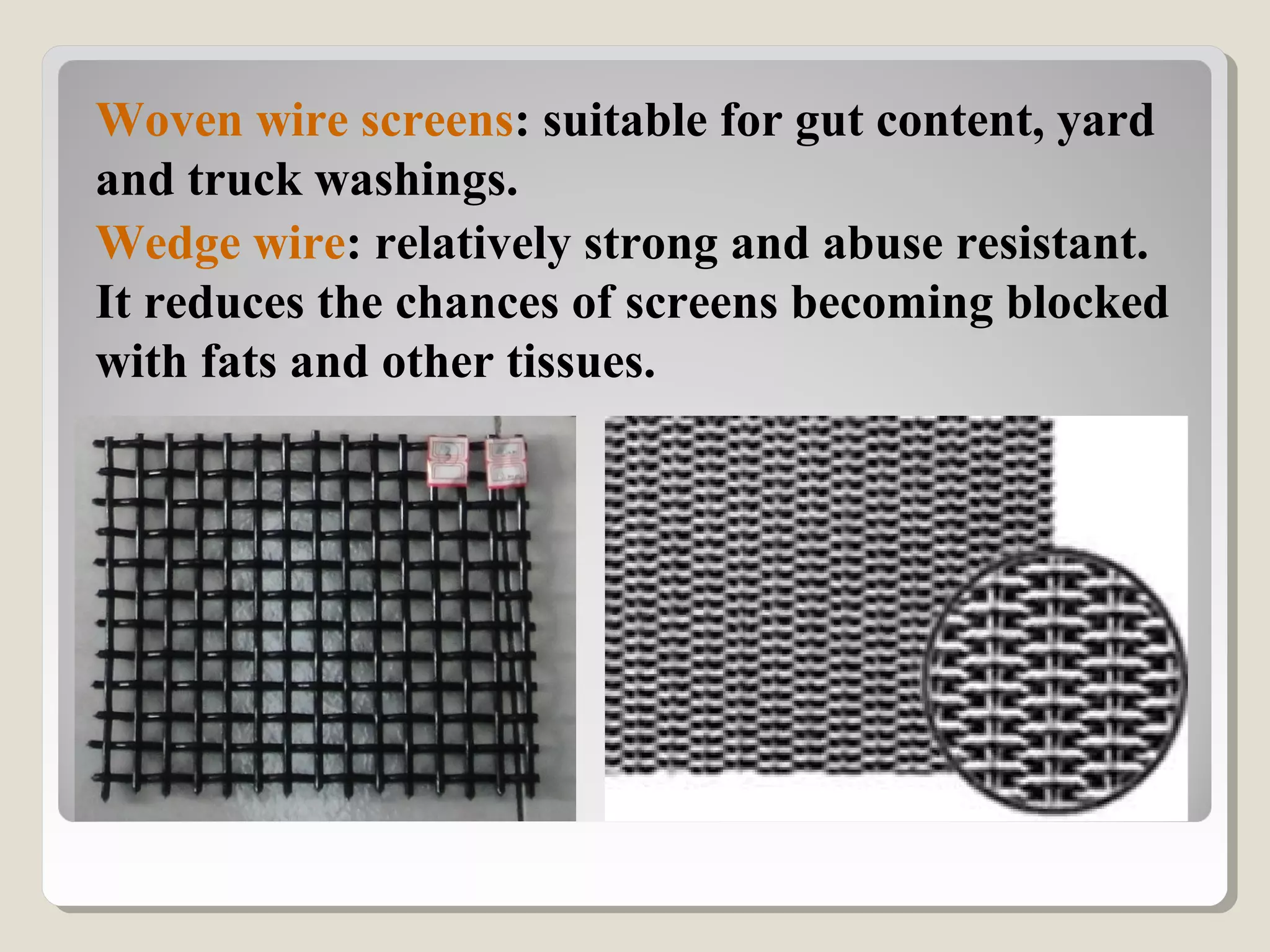

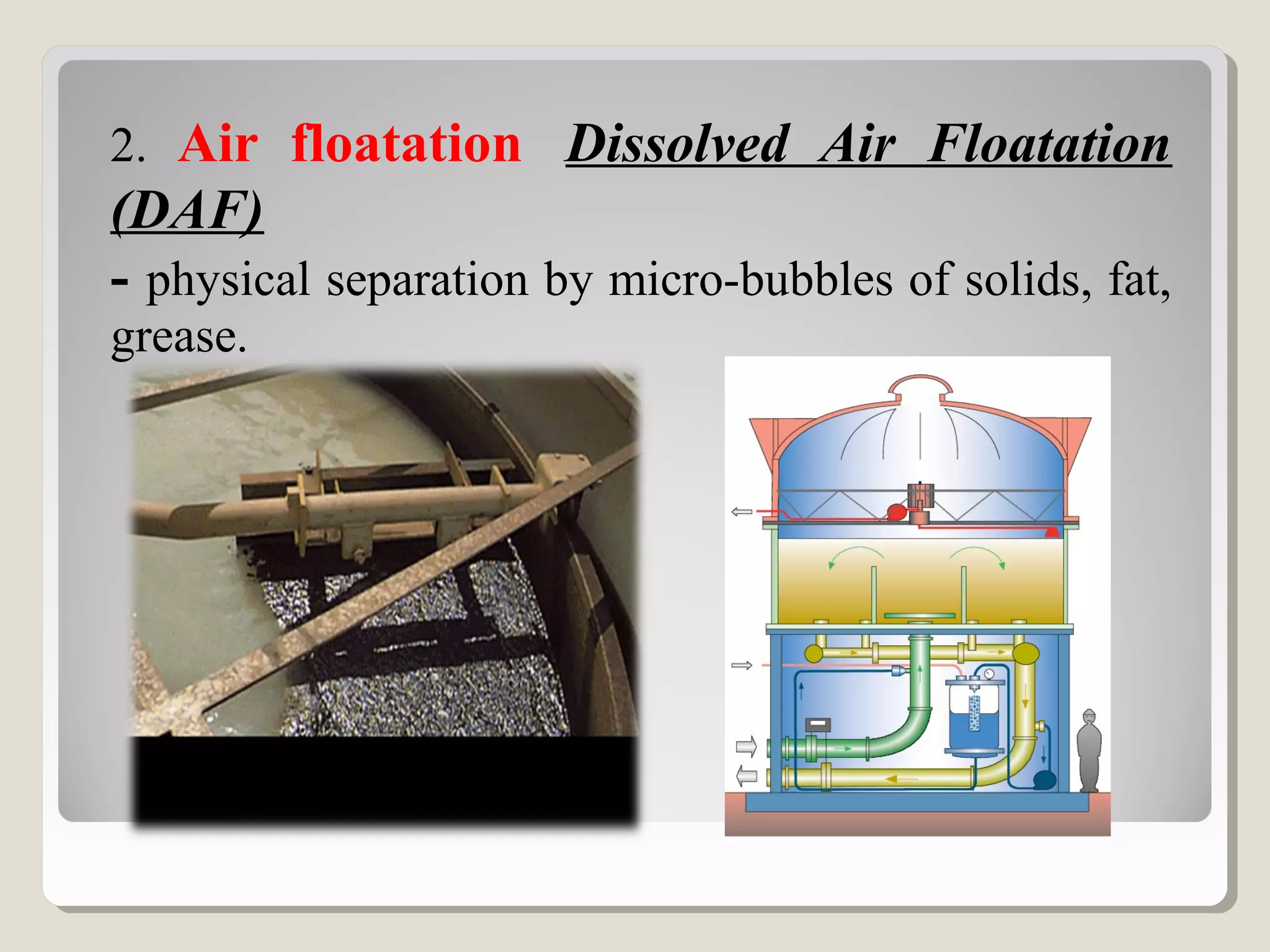

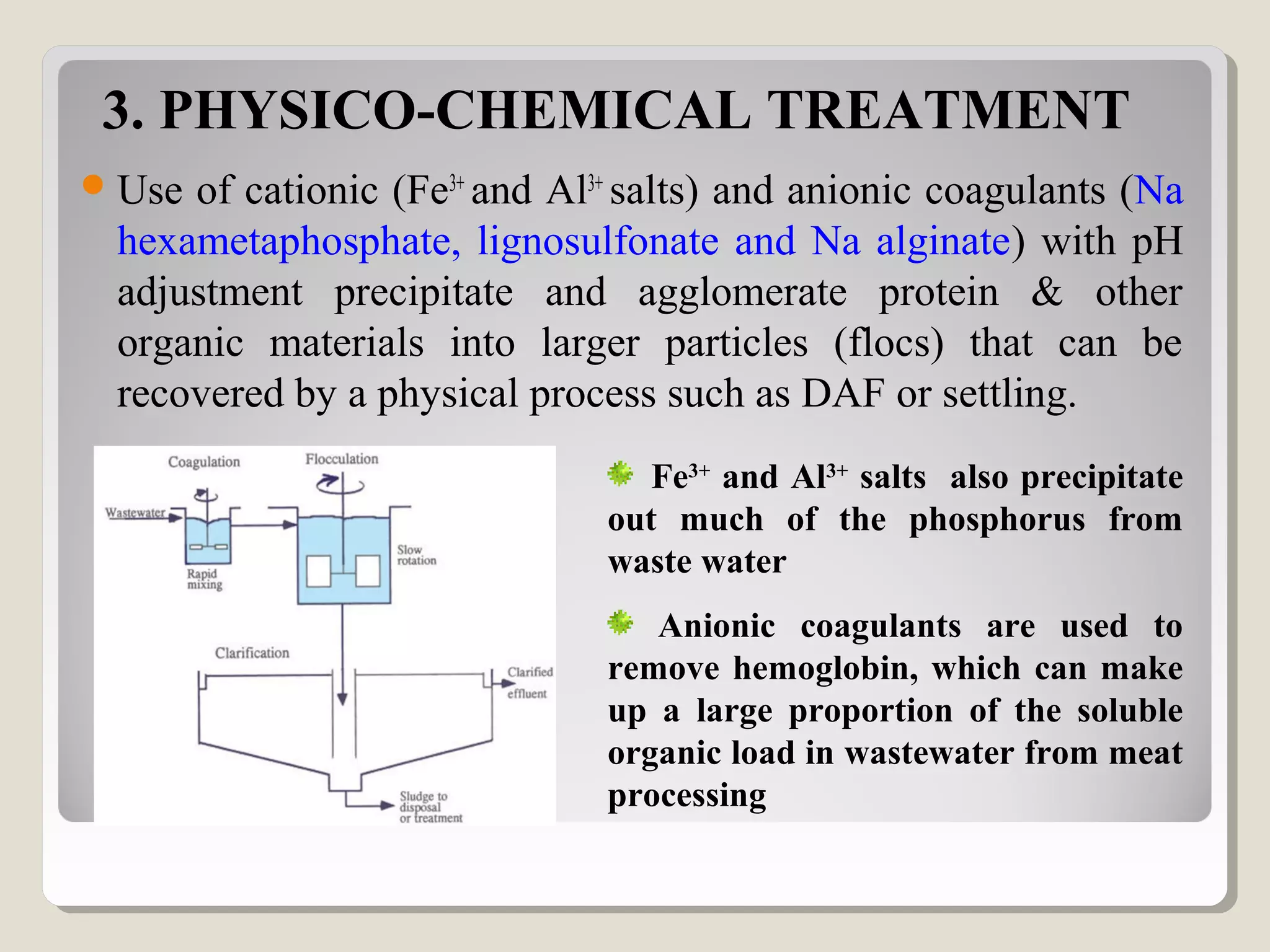

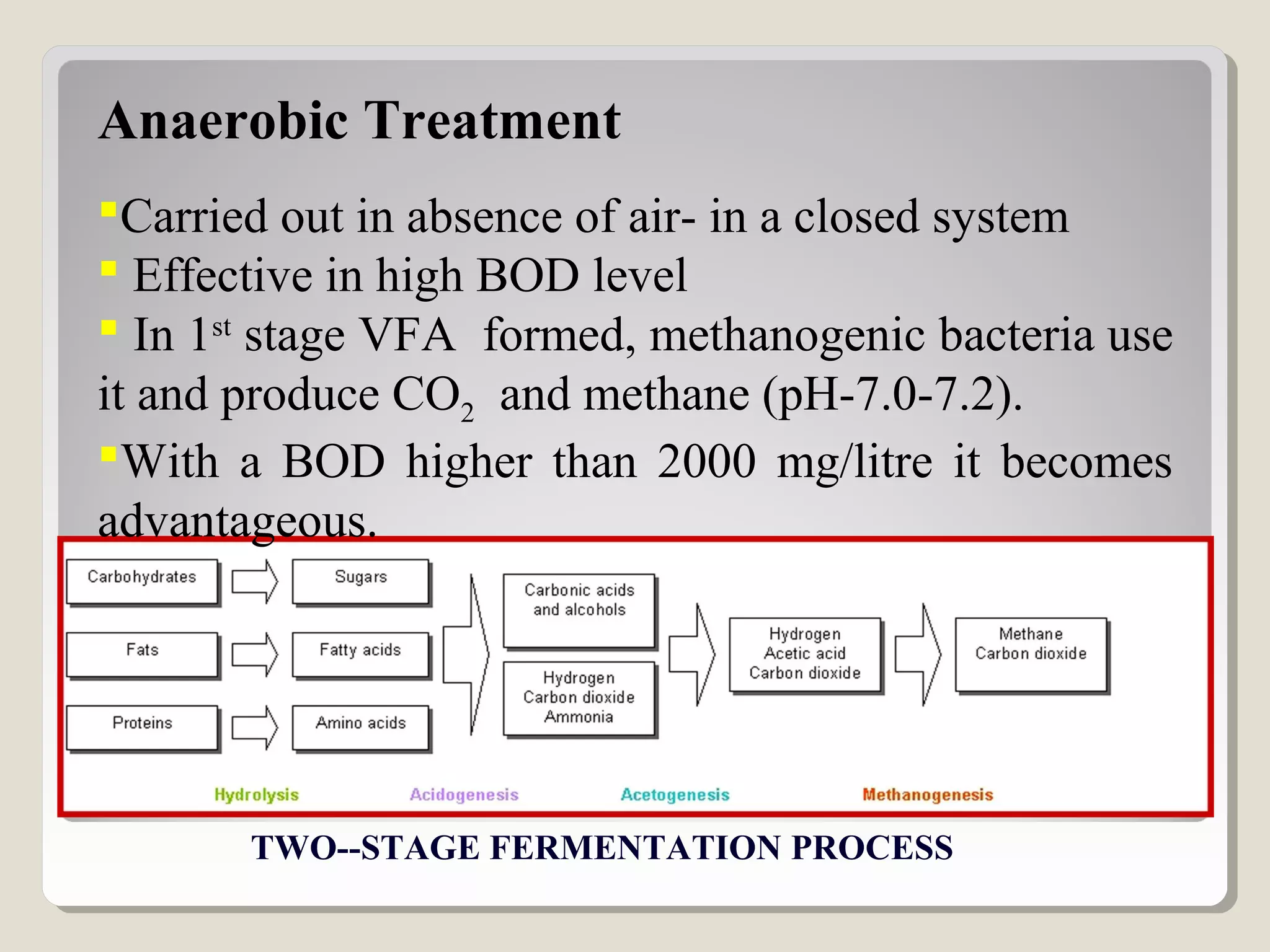

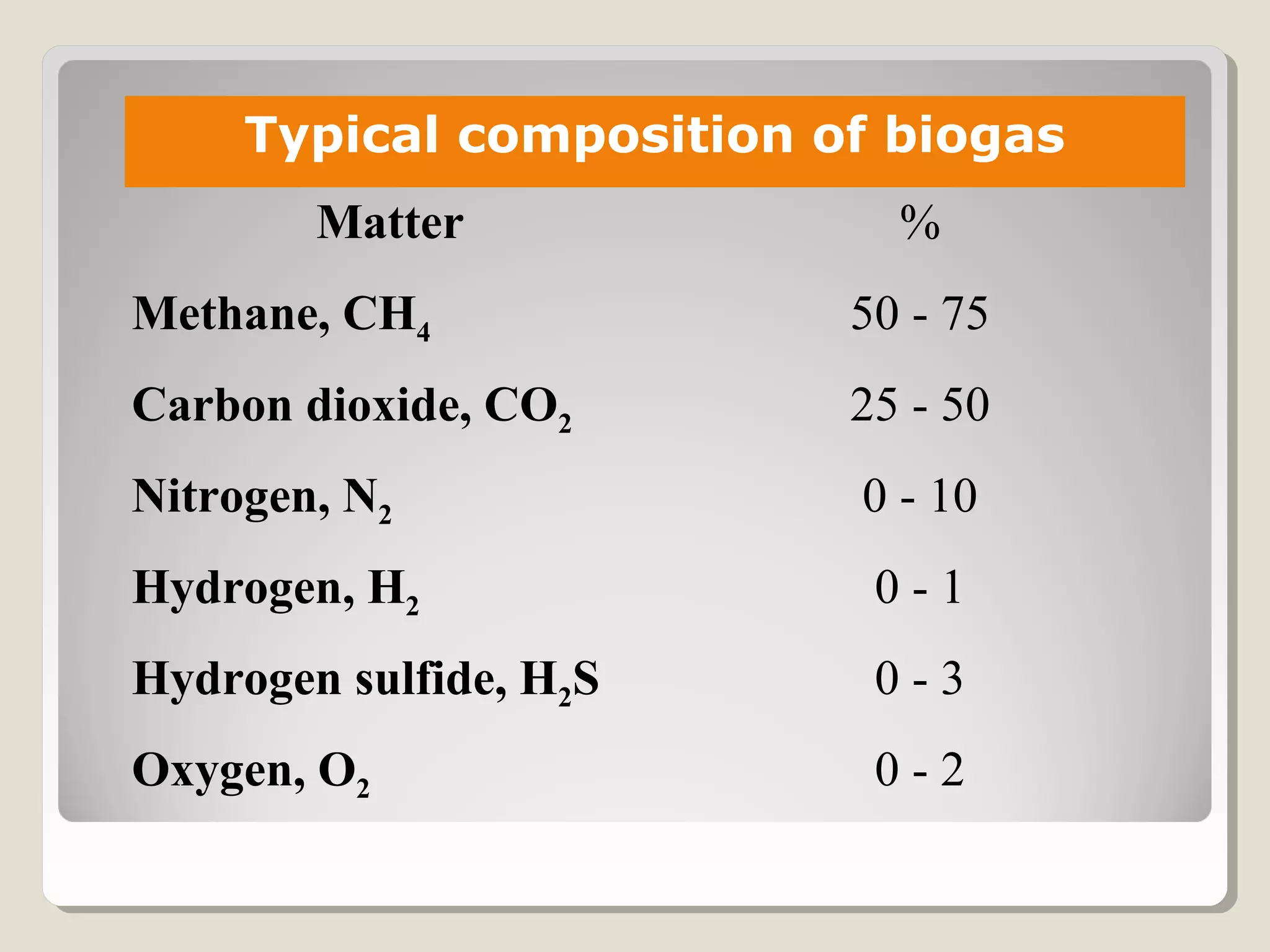

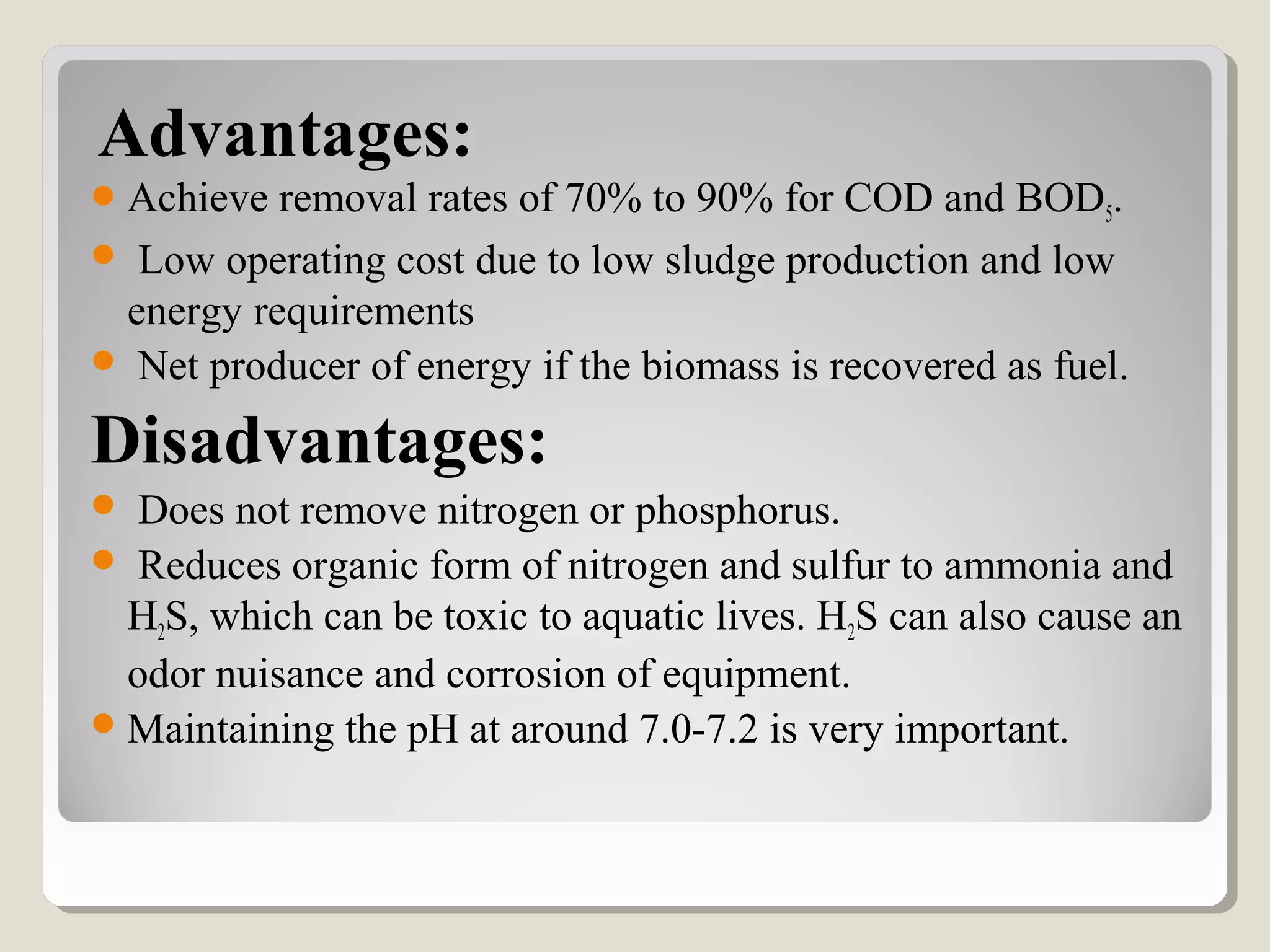

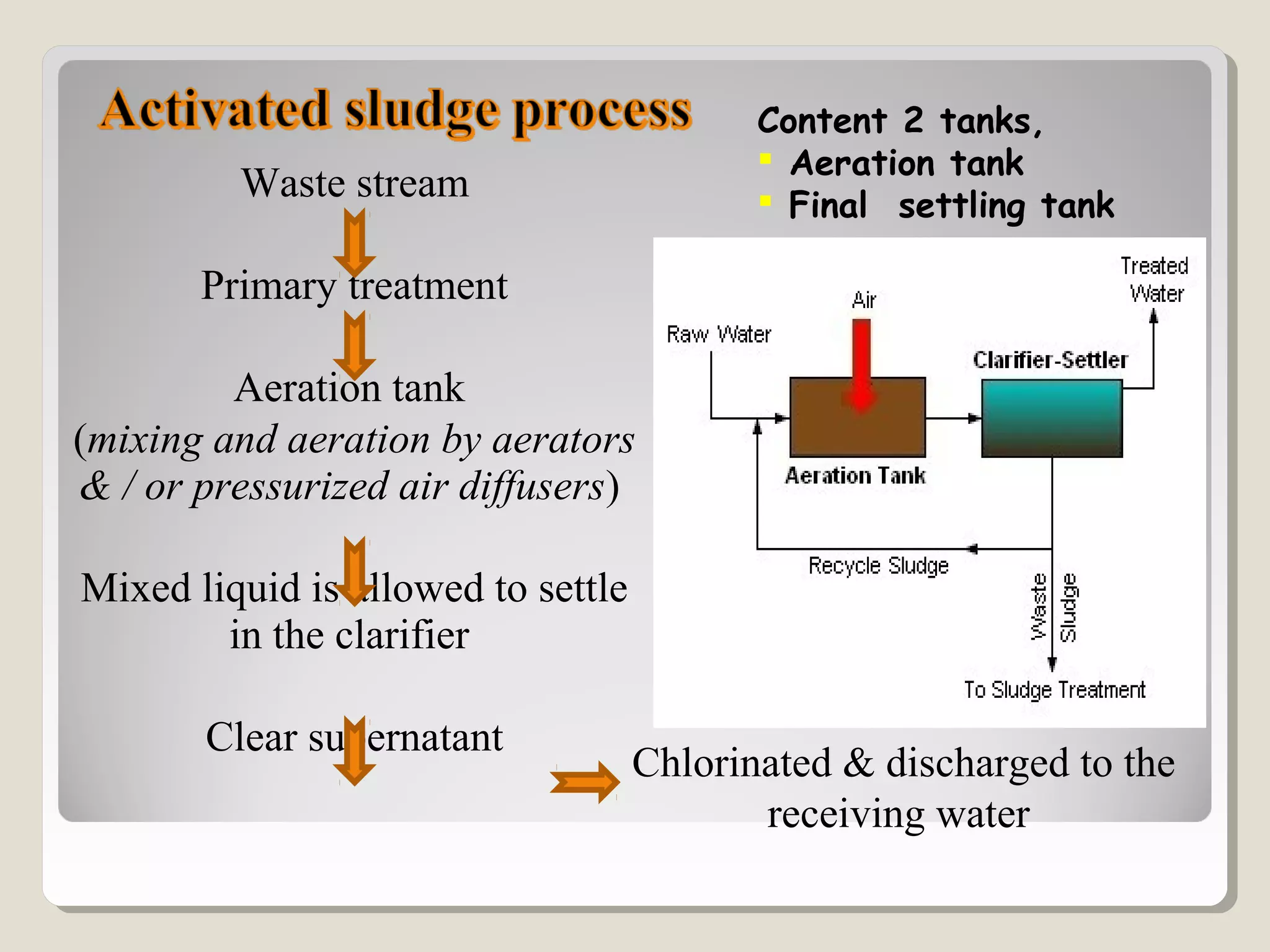

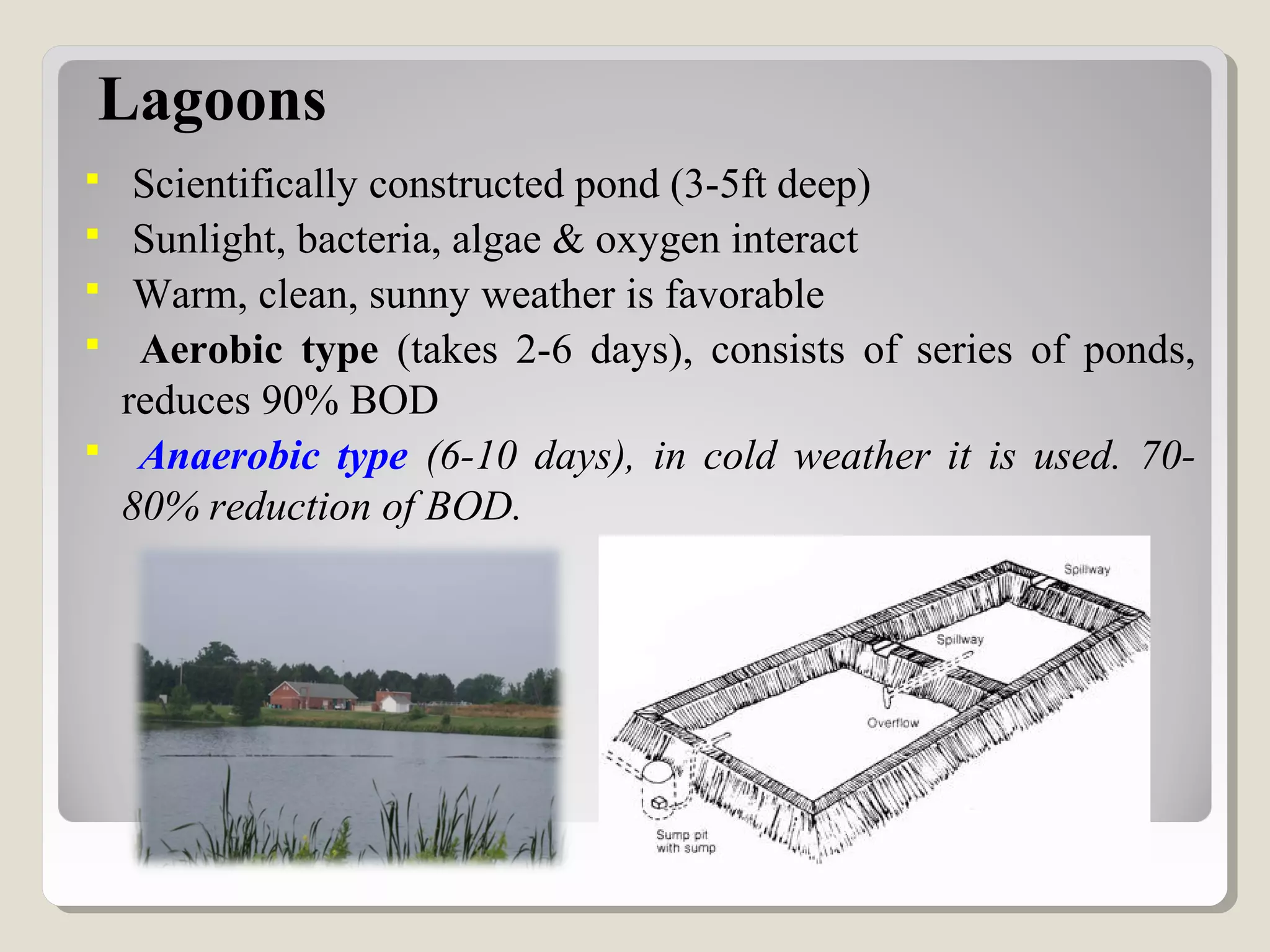

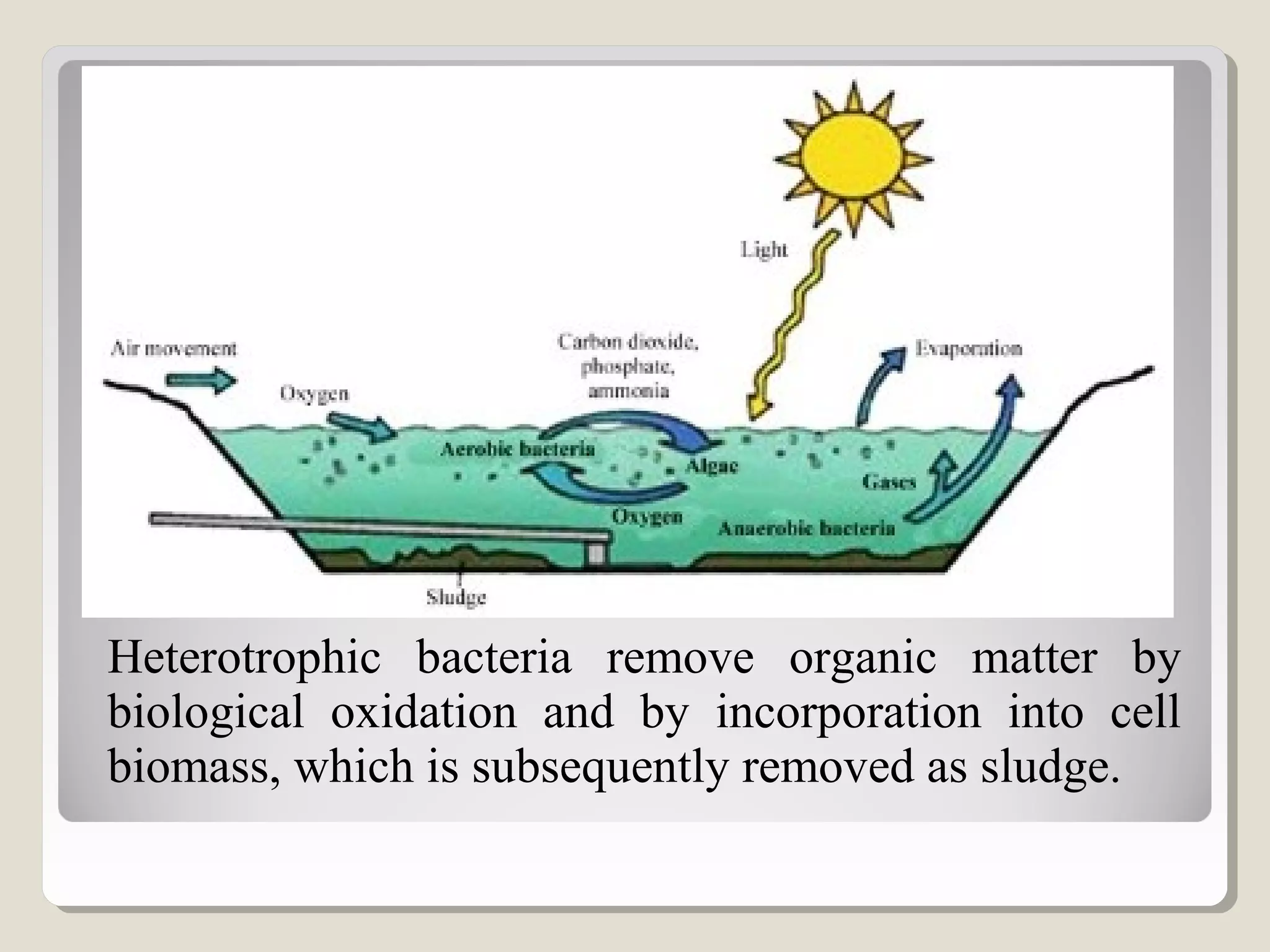

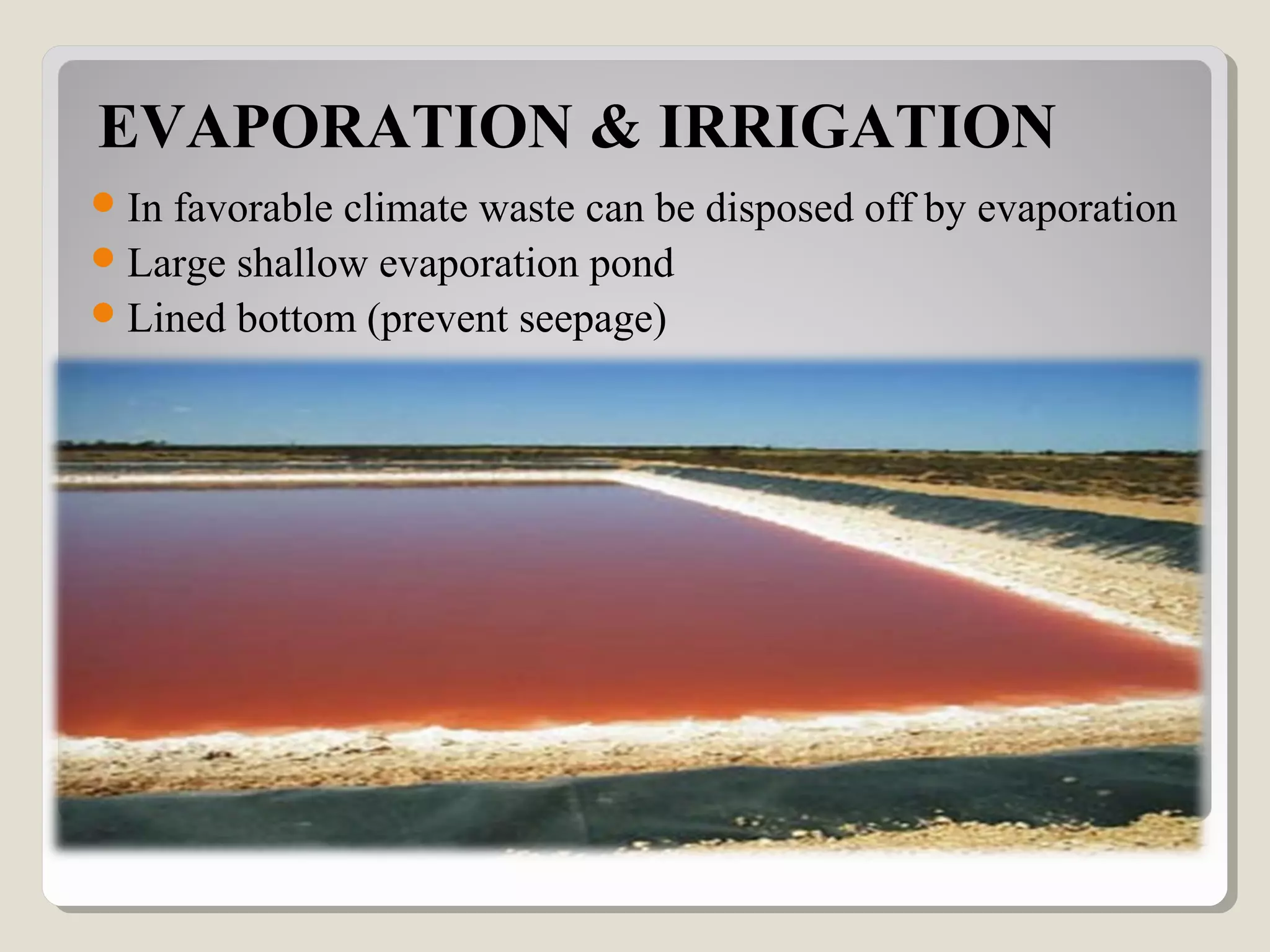

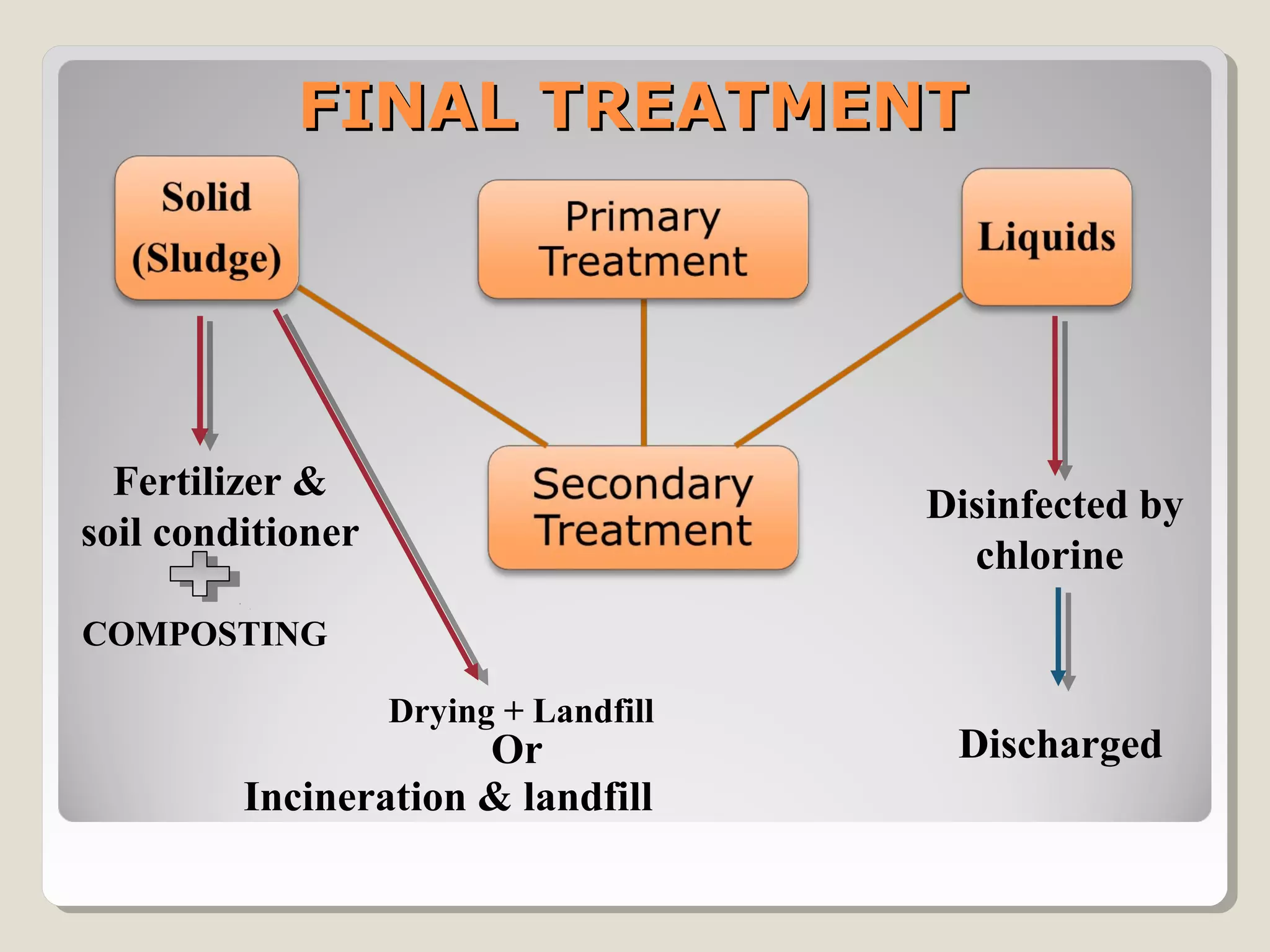

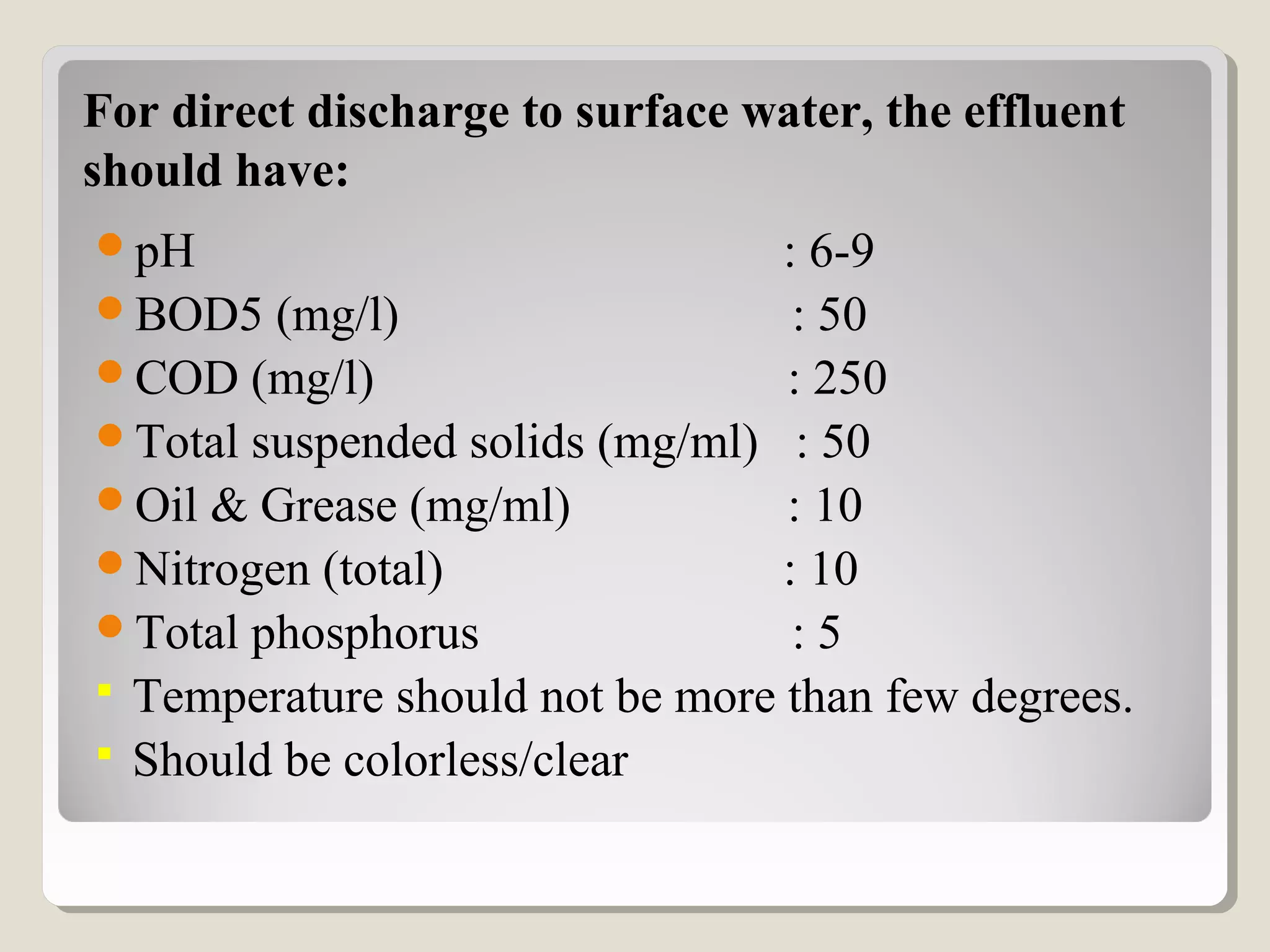

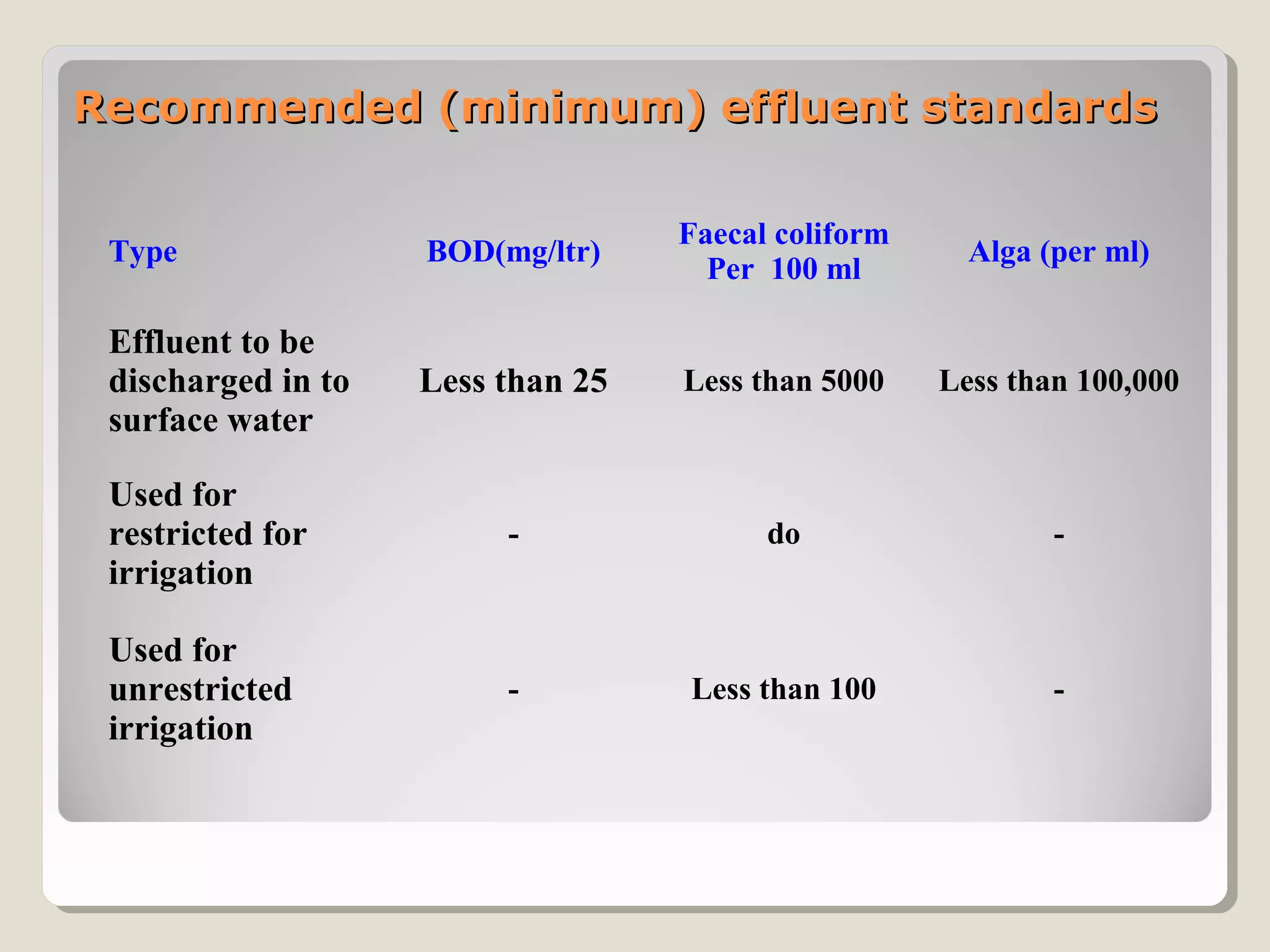

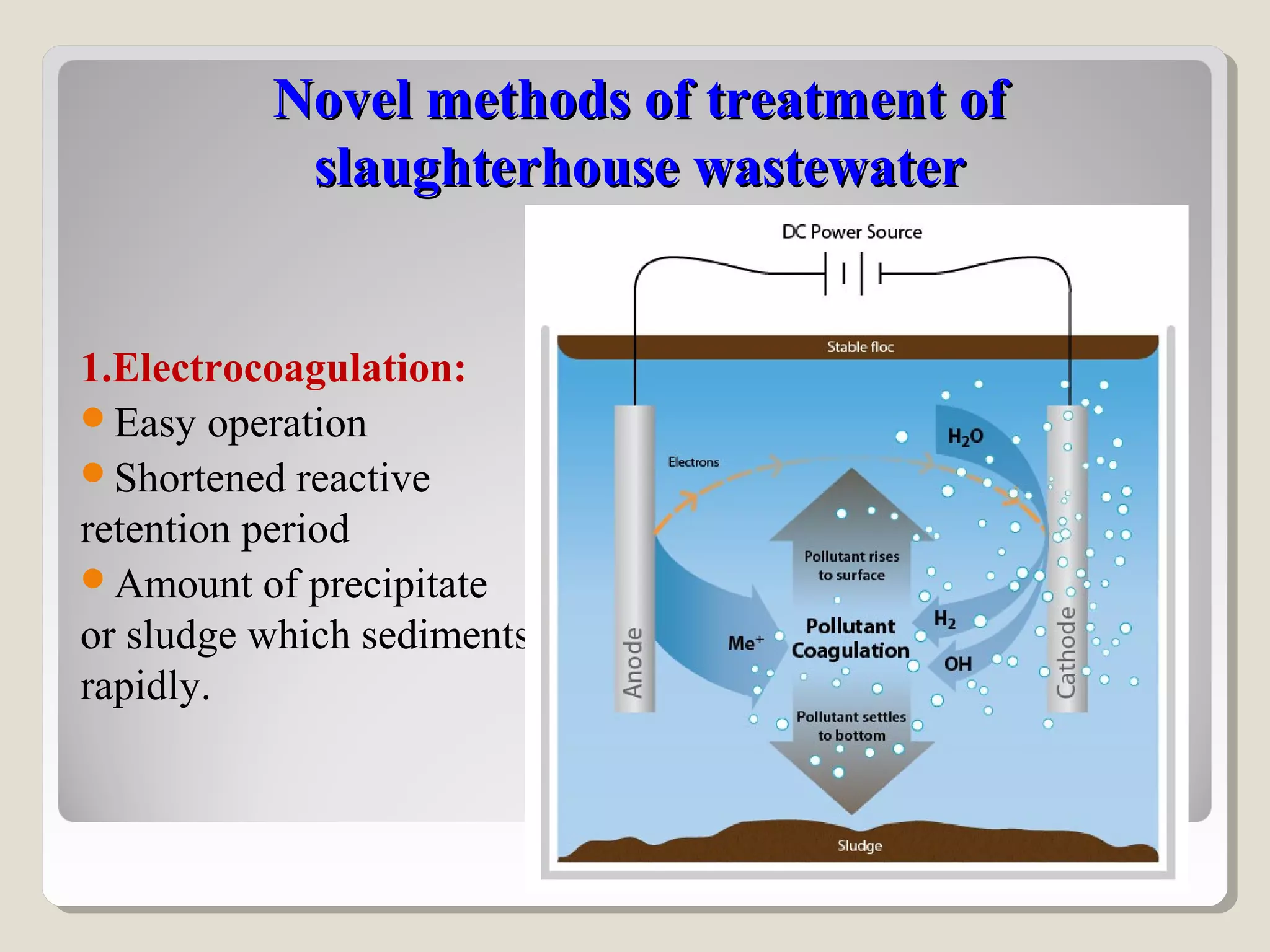

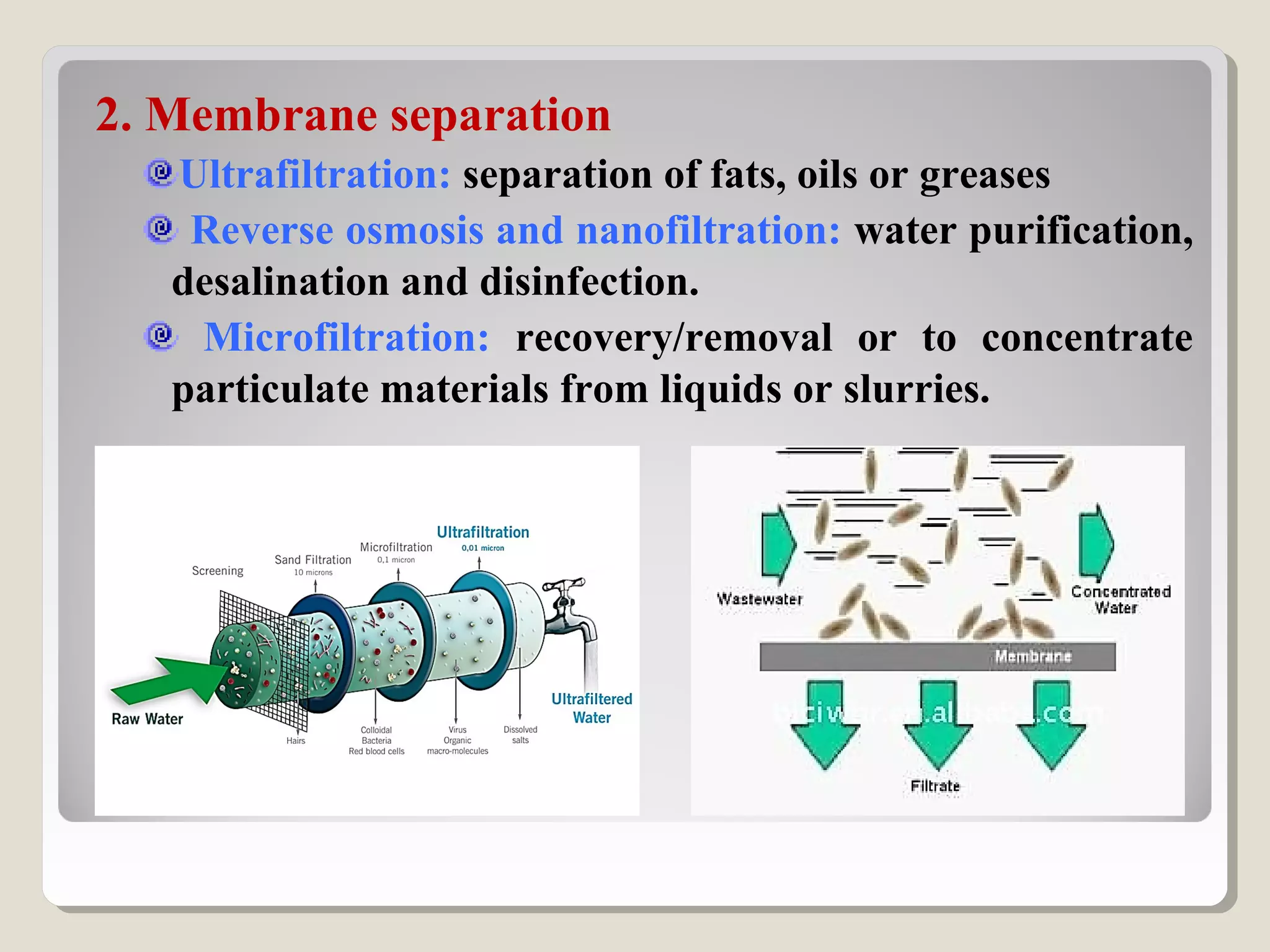

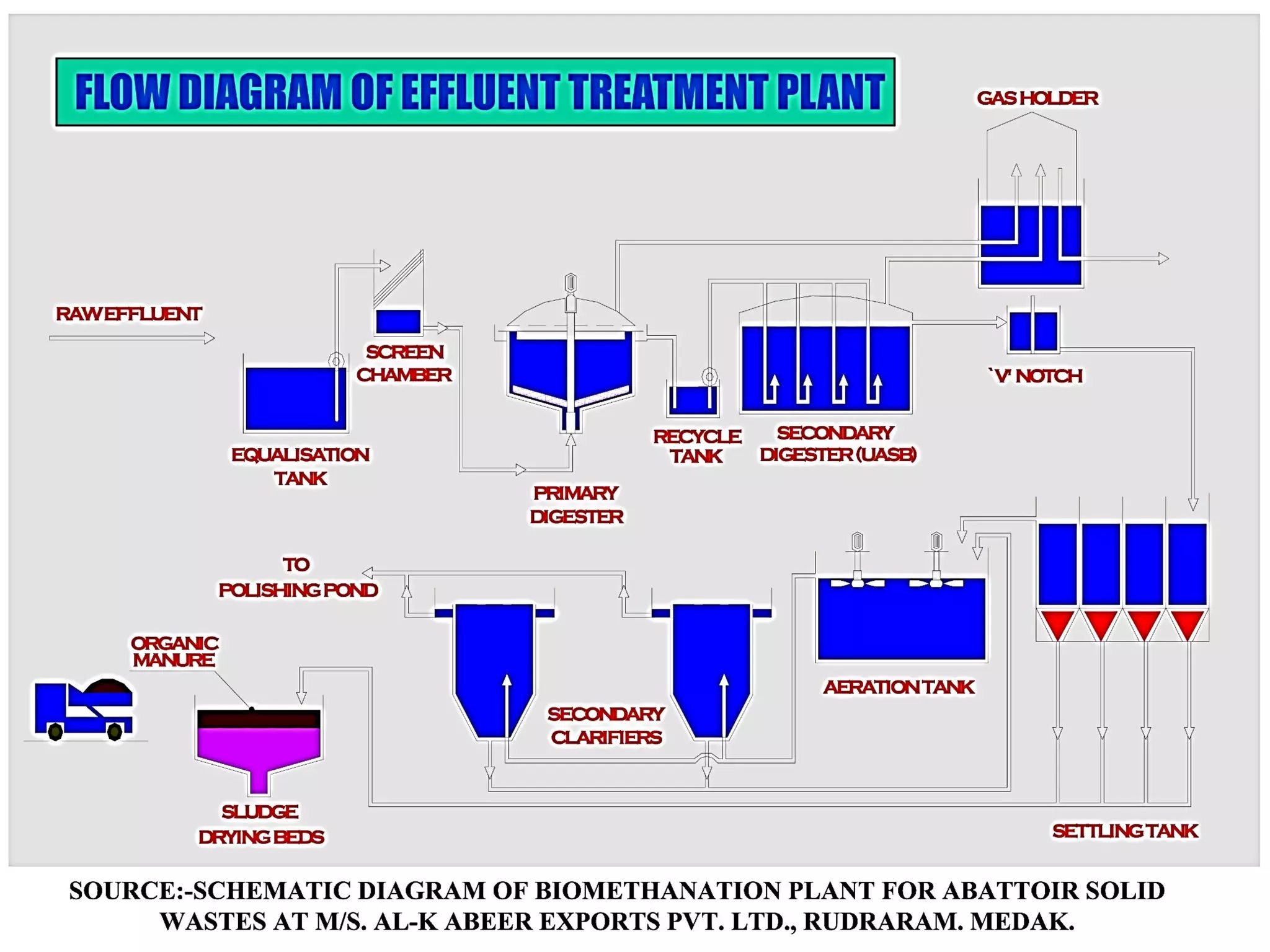

The document discusses the treatment of effluent generated from the meat industry, highlighting the importance of efficient disposal due to its potential pollution impact. It outlines different types of pollutants in effluents, treatment methods including primary, secondary, and final treatments, as well as the characteristics and pollution parameters of meat processing waste. The document emphasizes the need for regulatory compliance to ensure safe discharge into the environment.