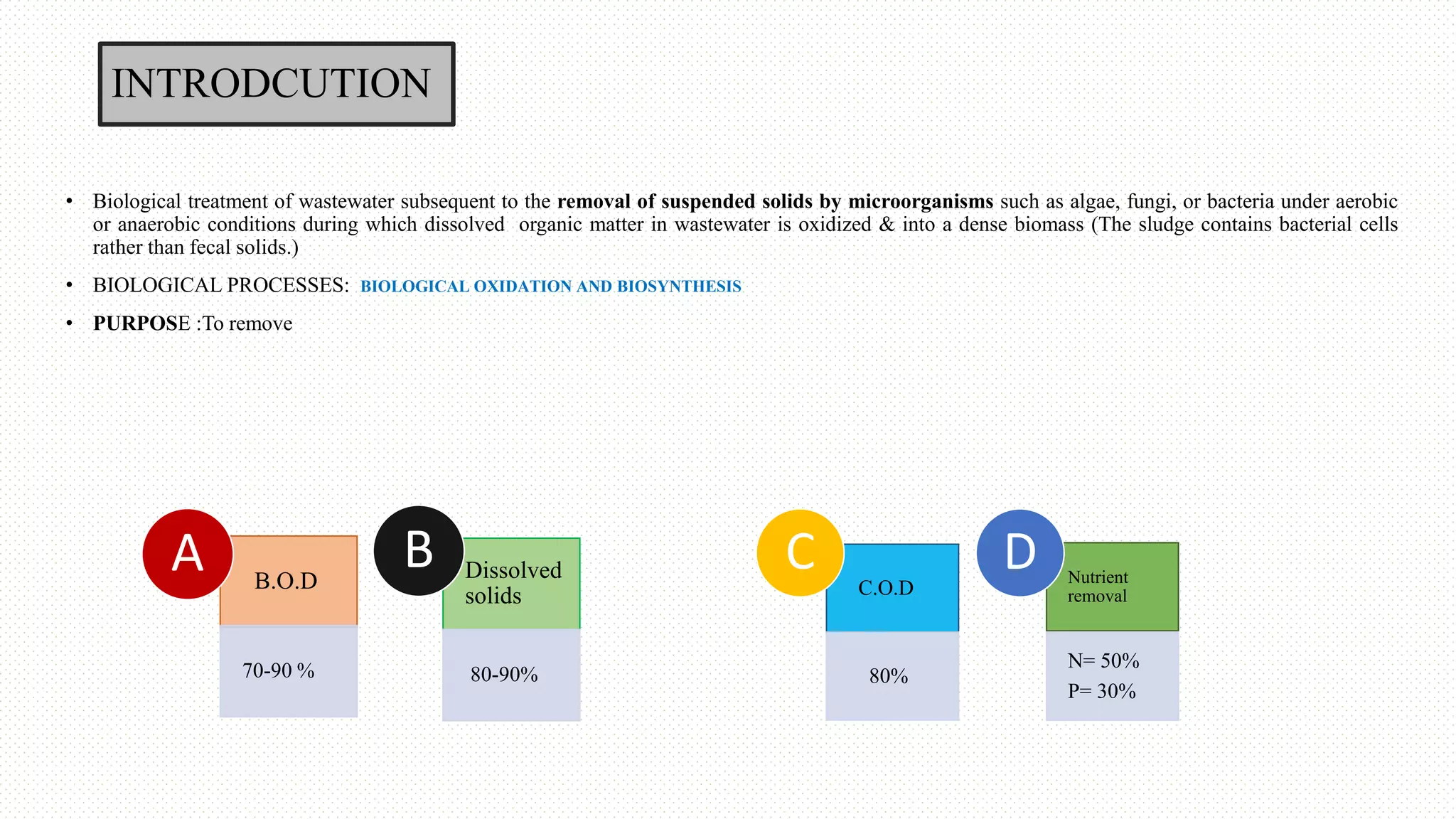

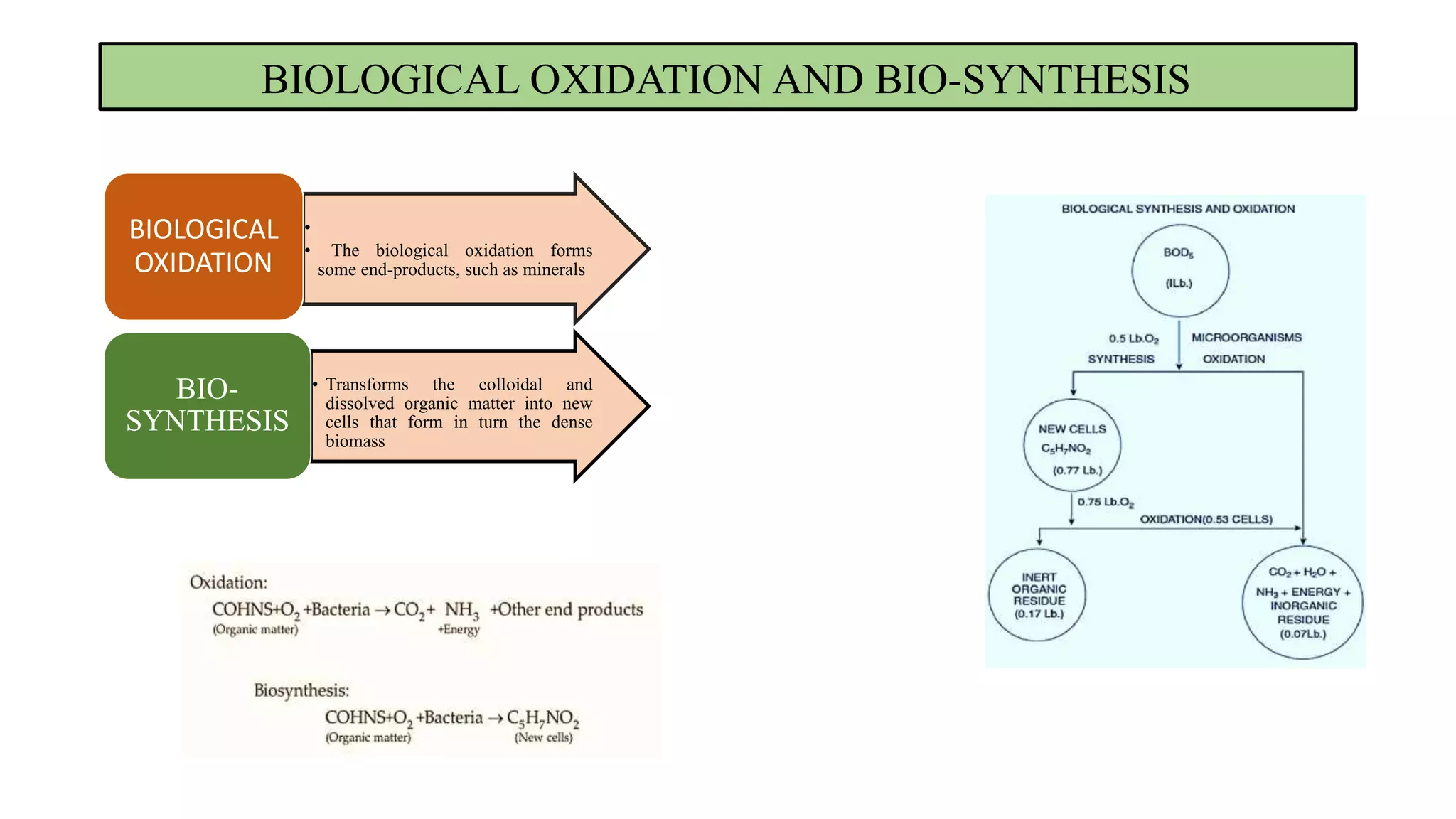

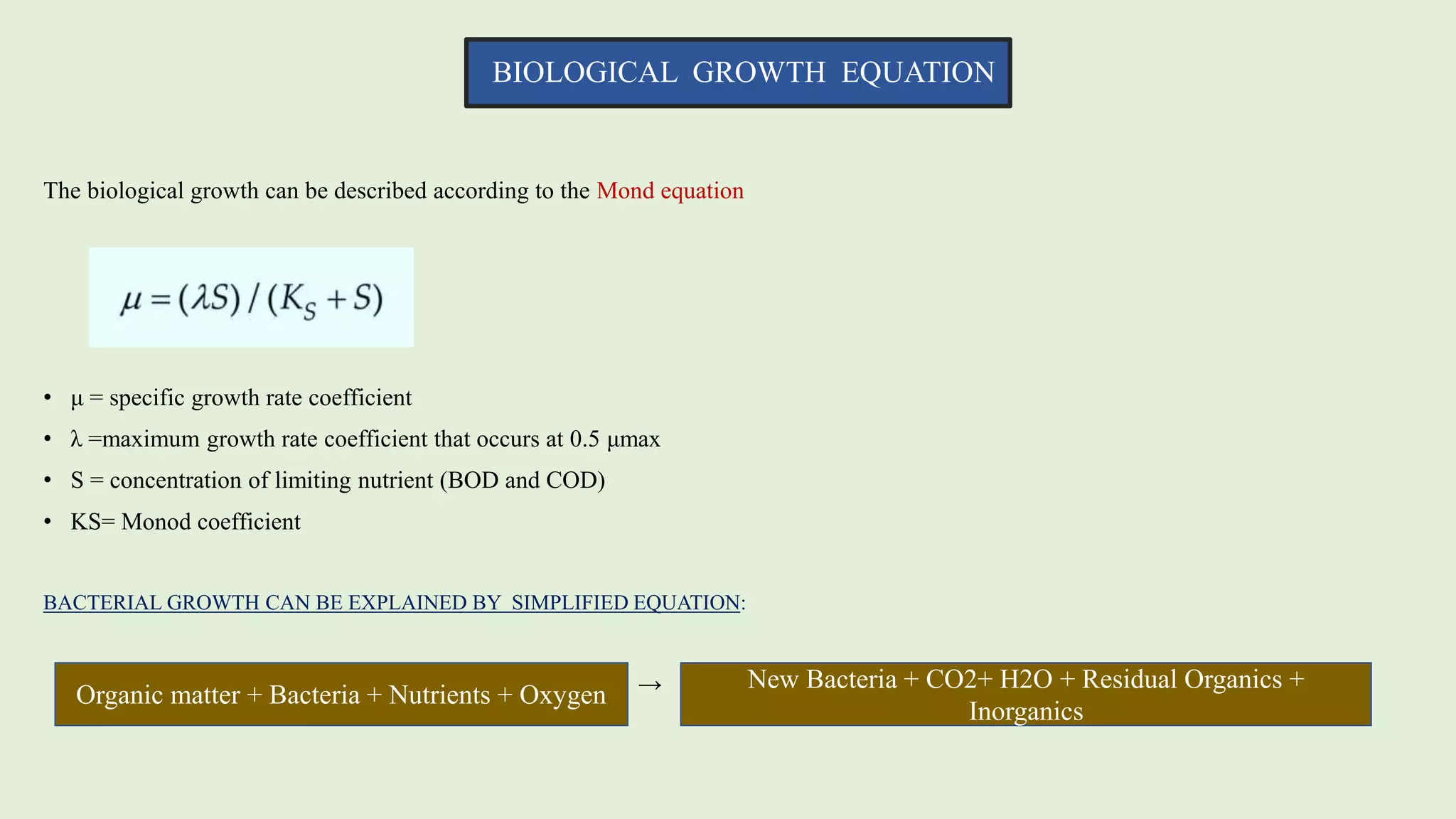

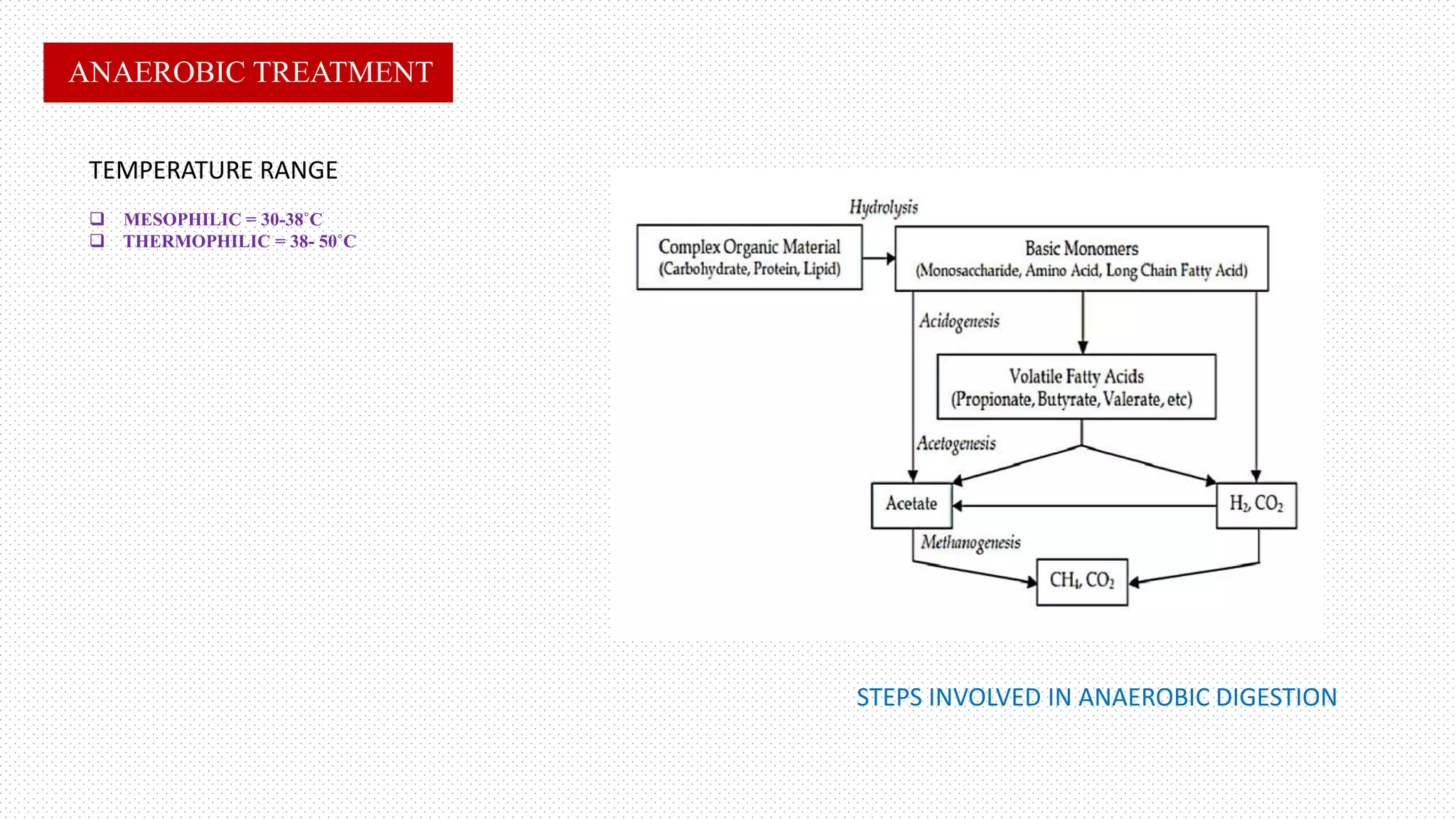

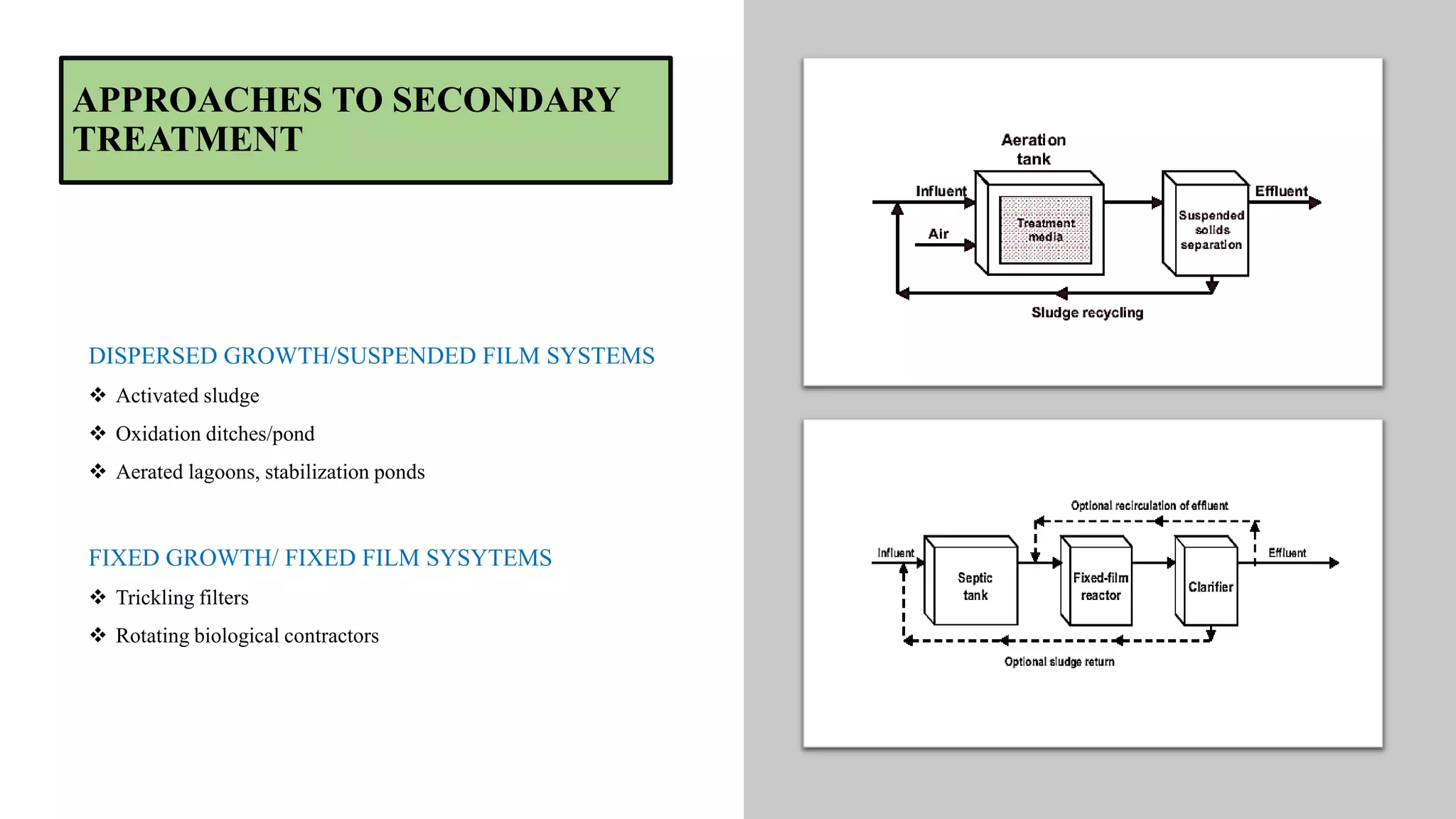

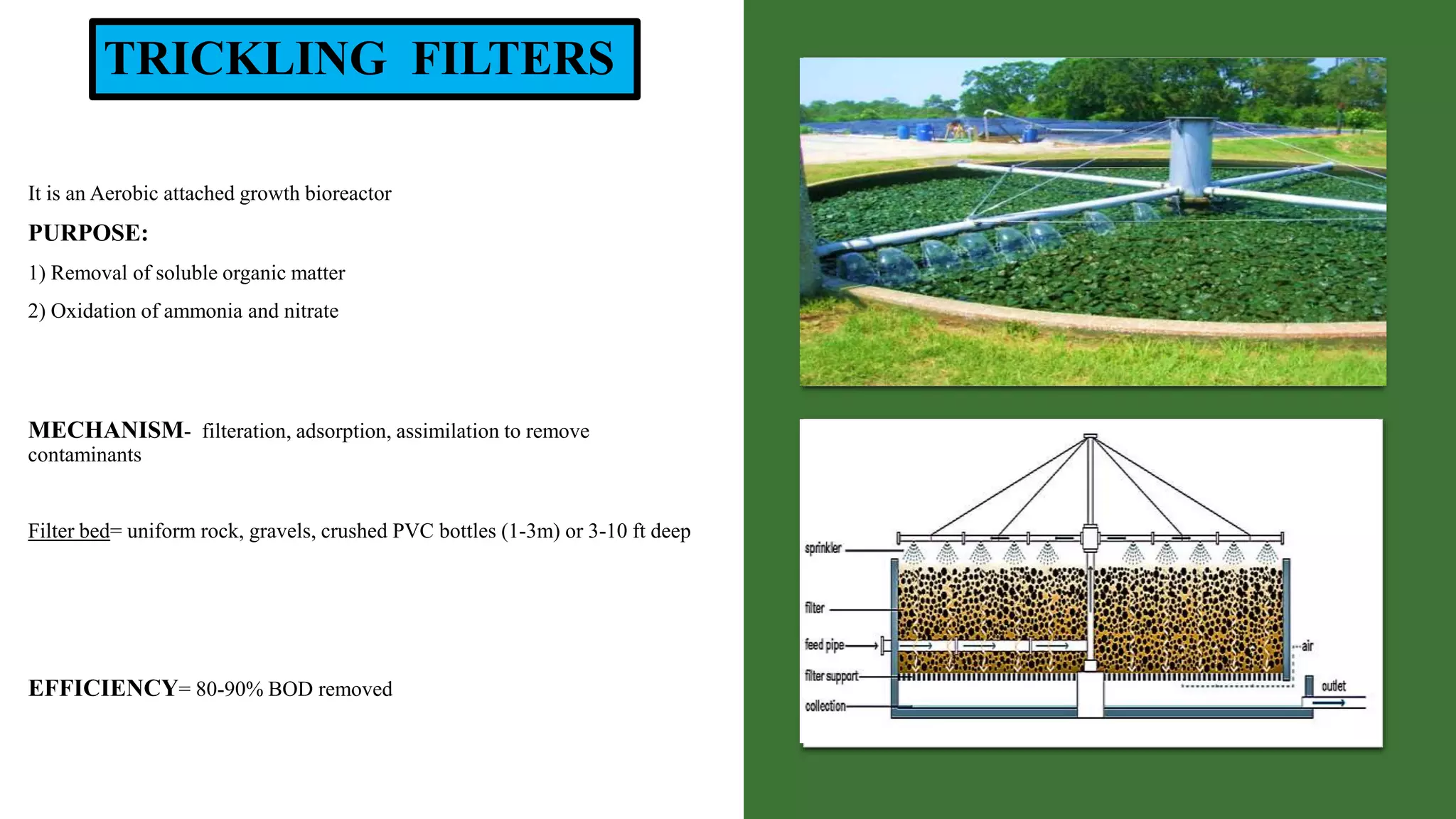

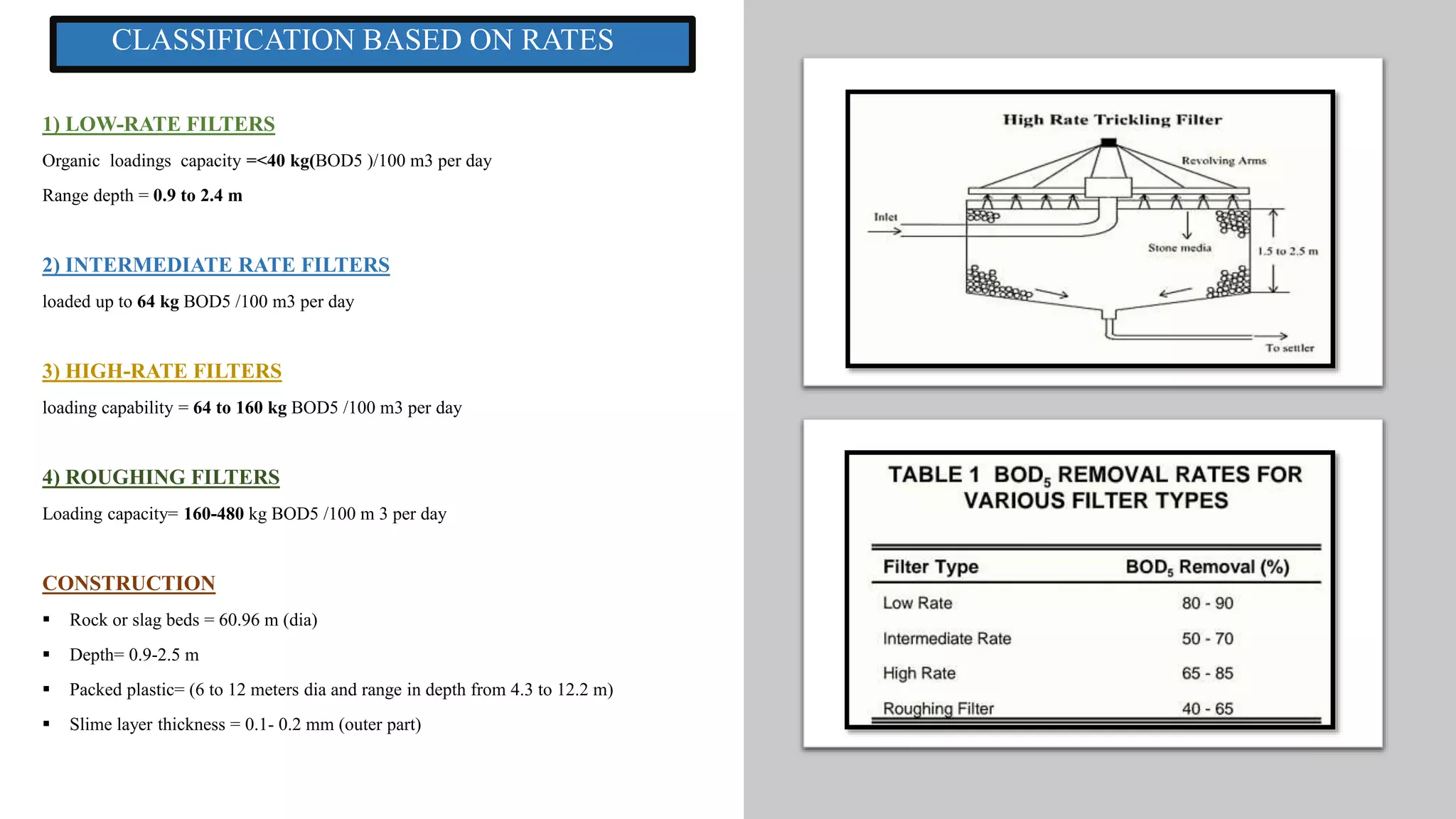

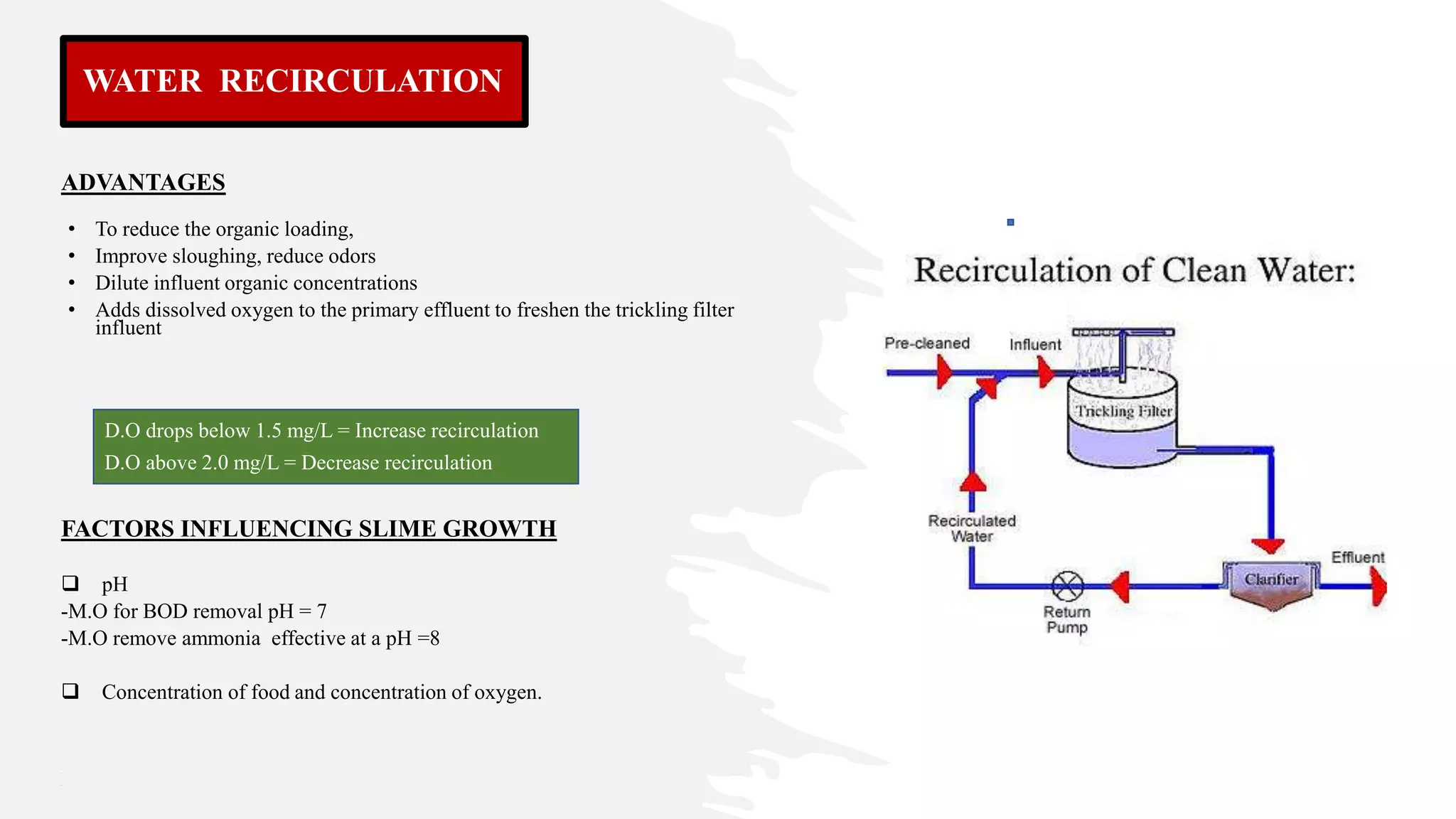

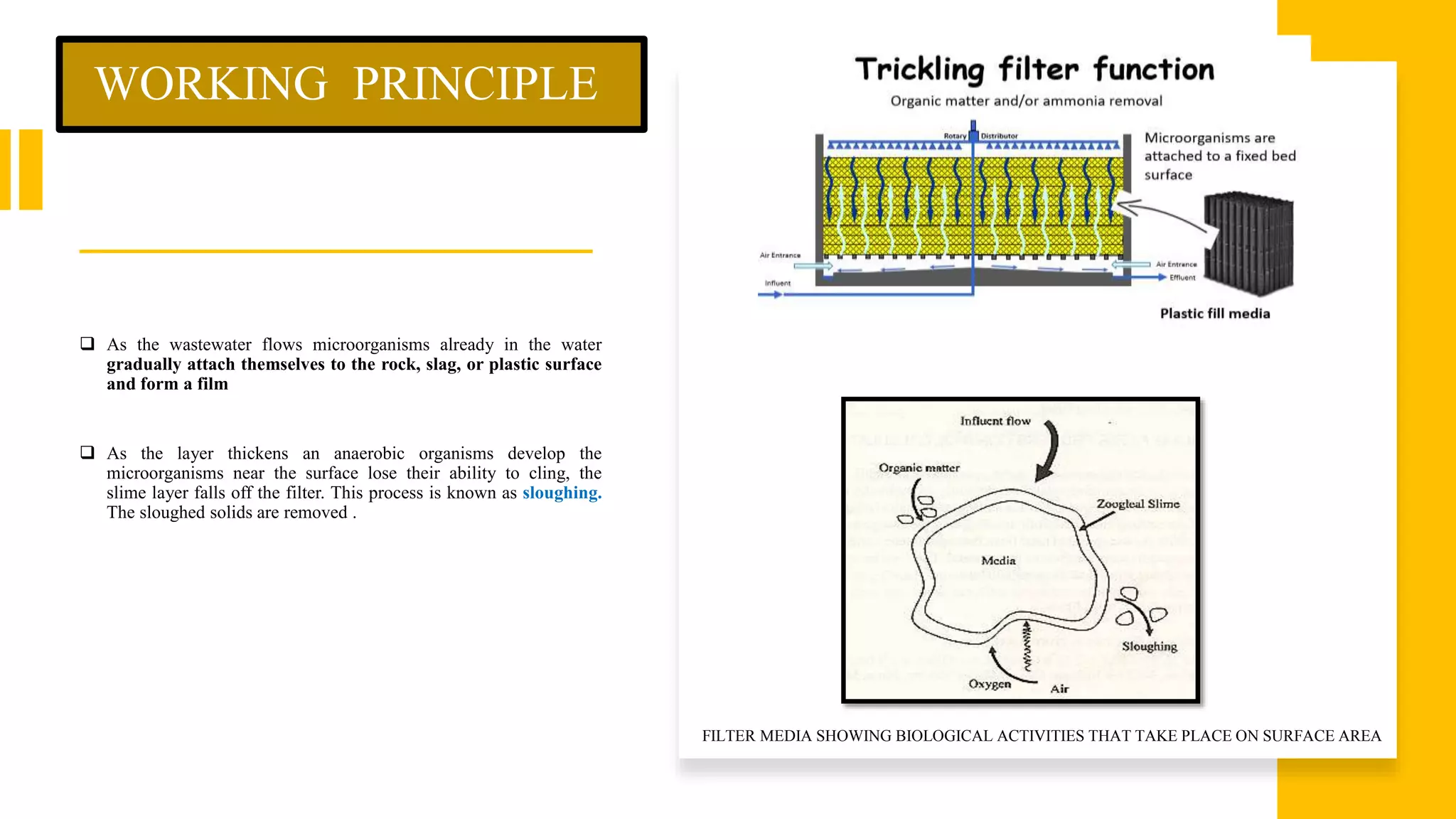

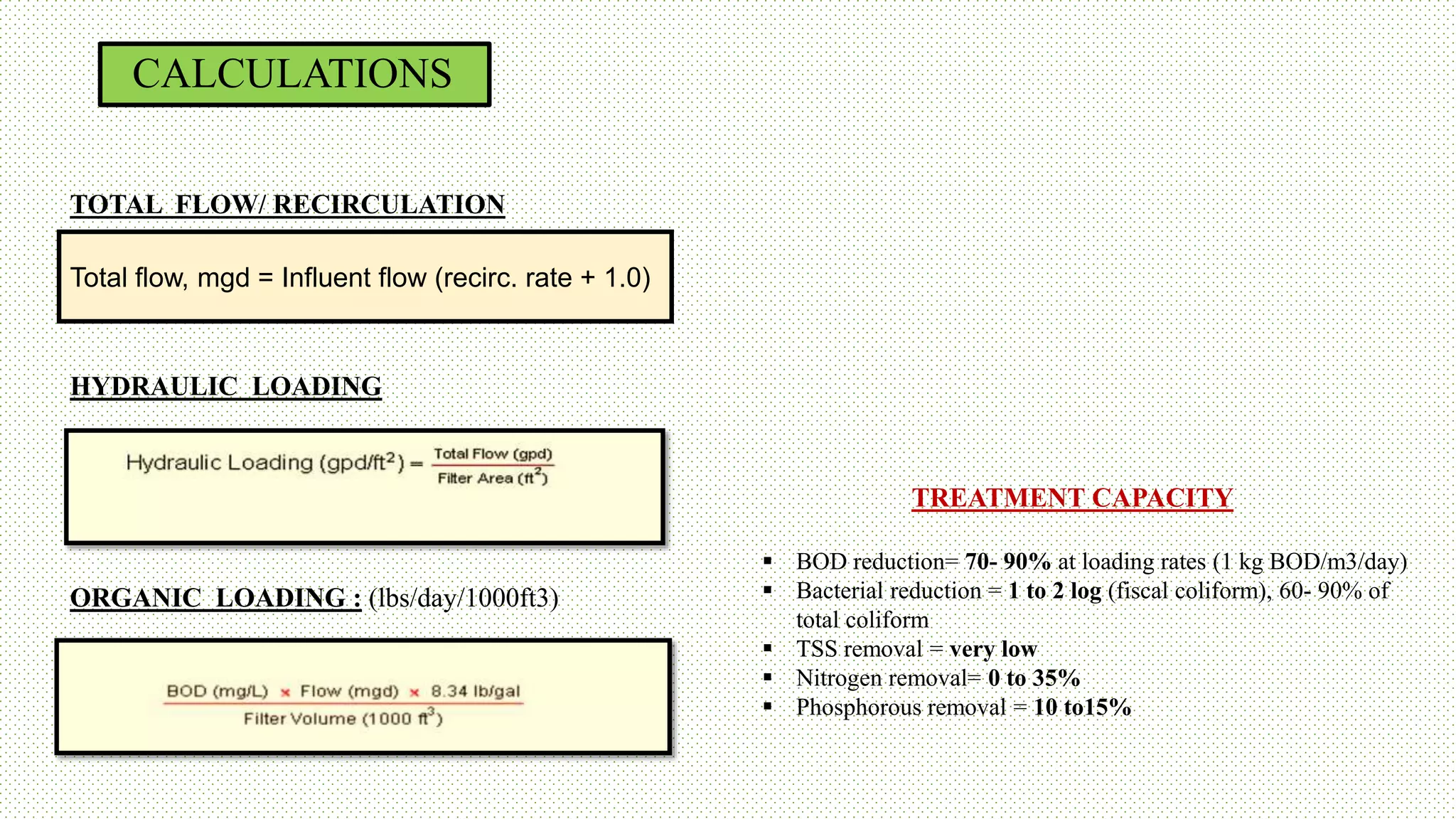

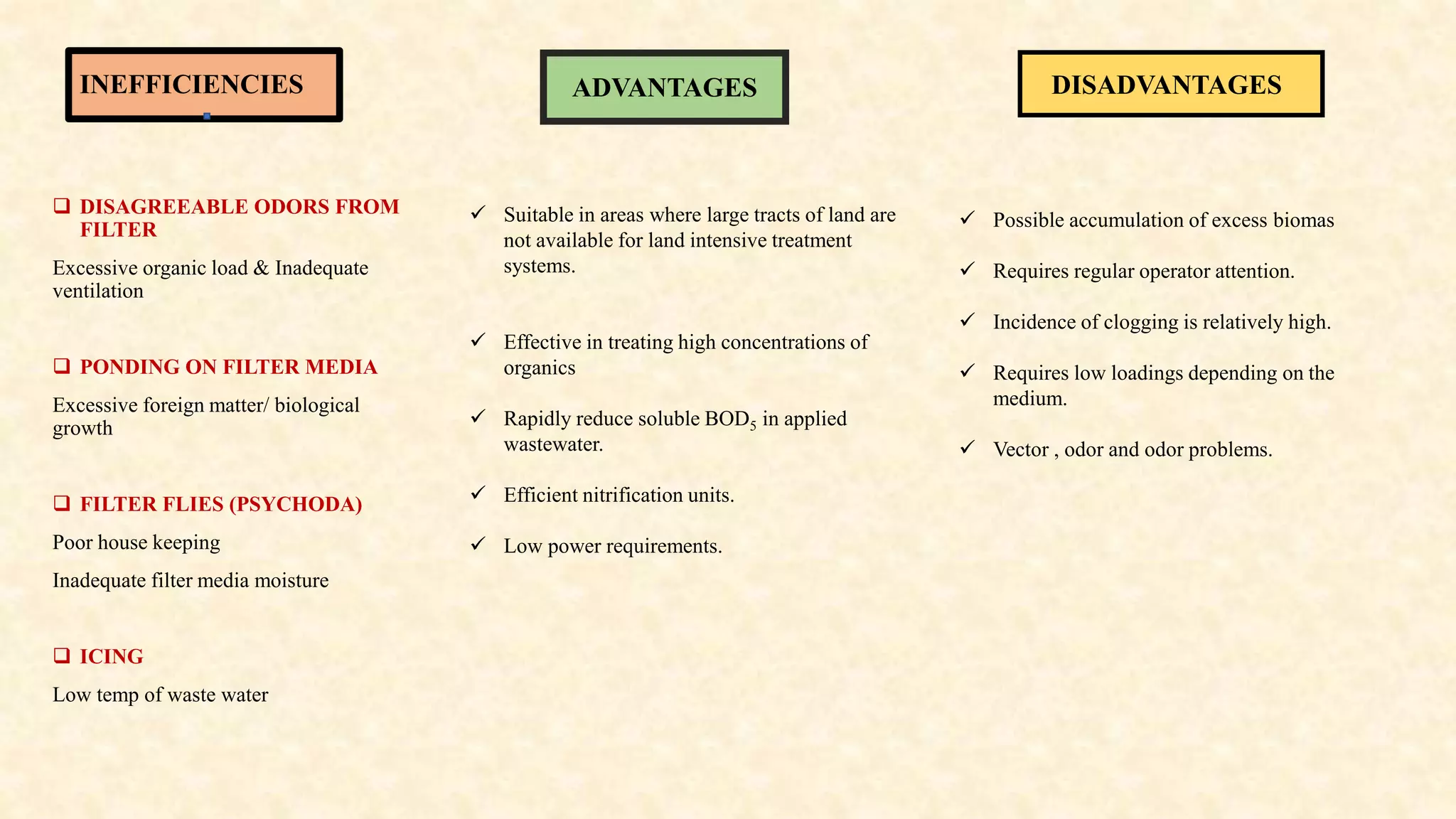

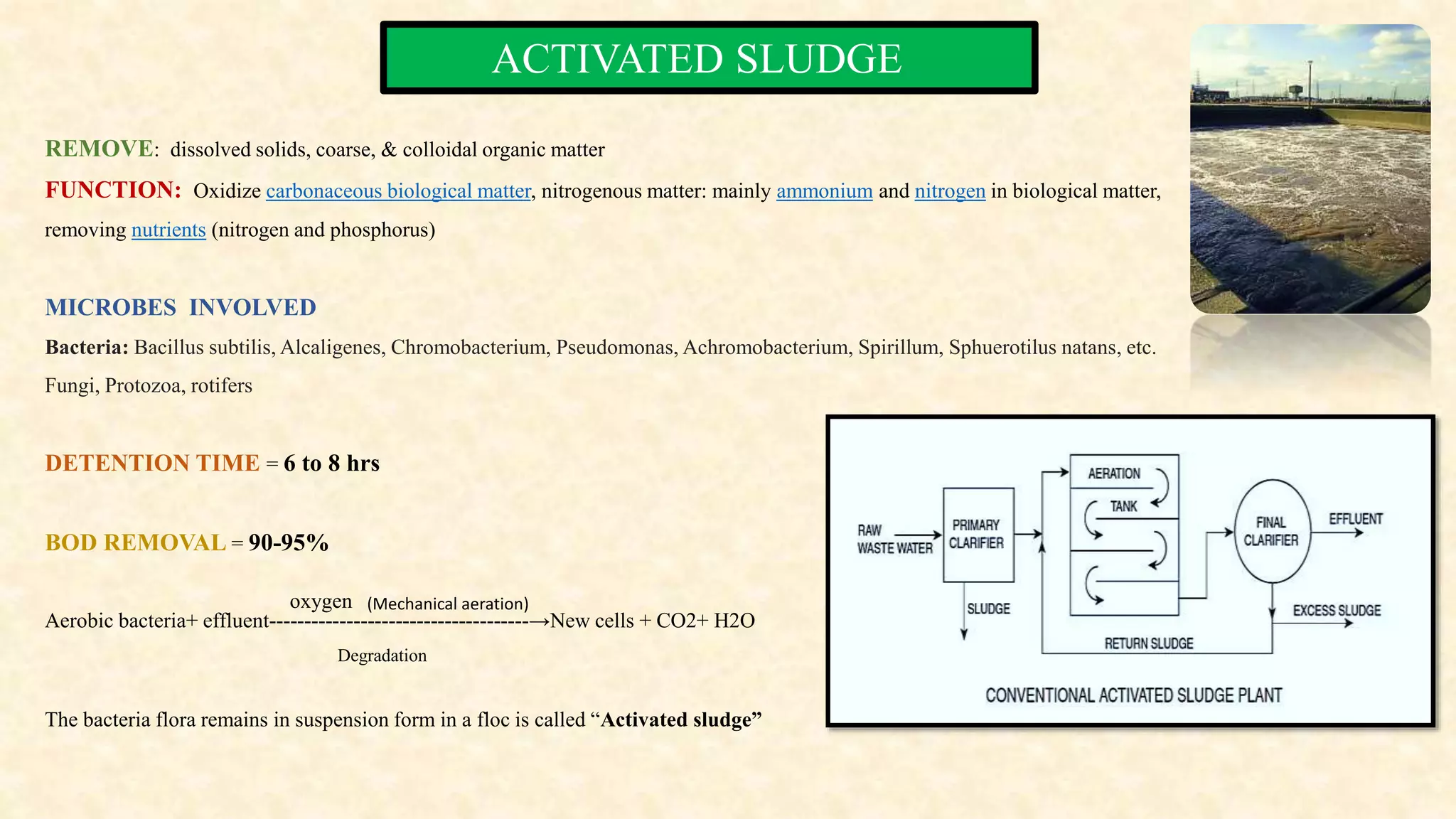

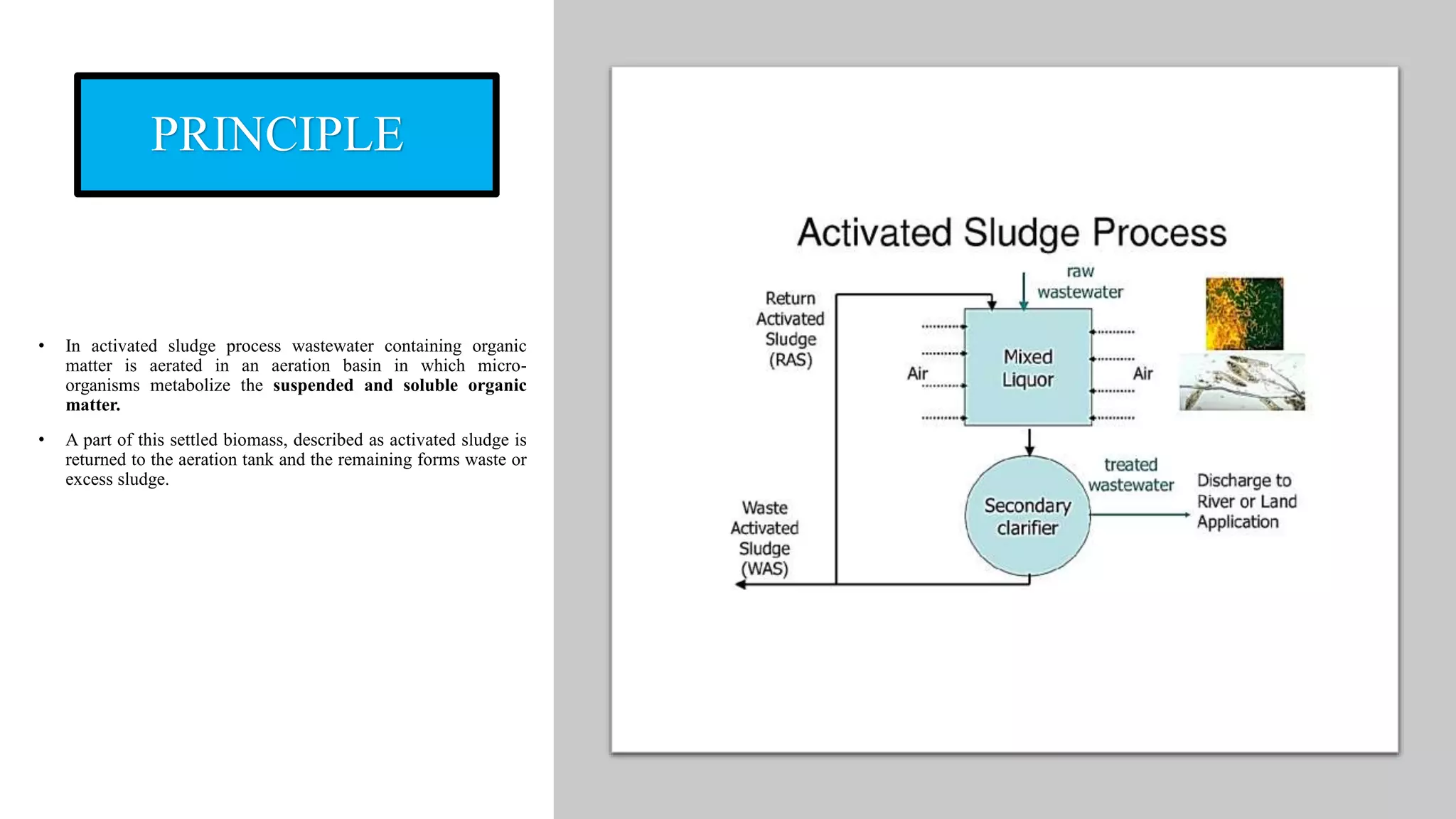

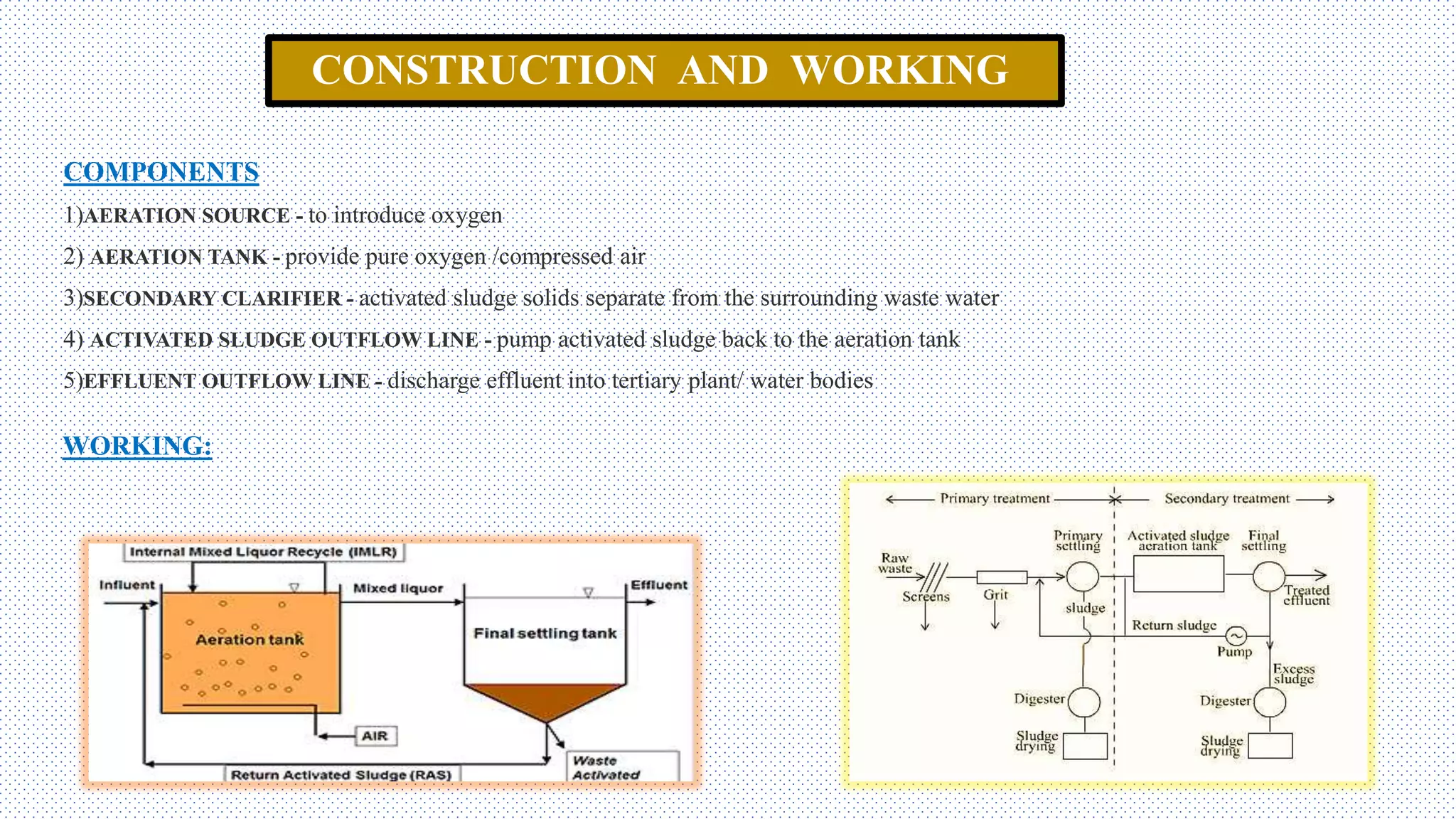

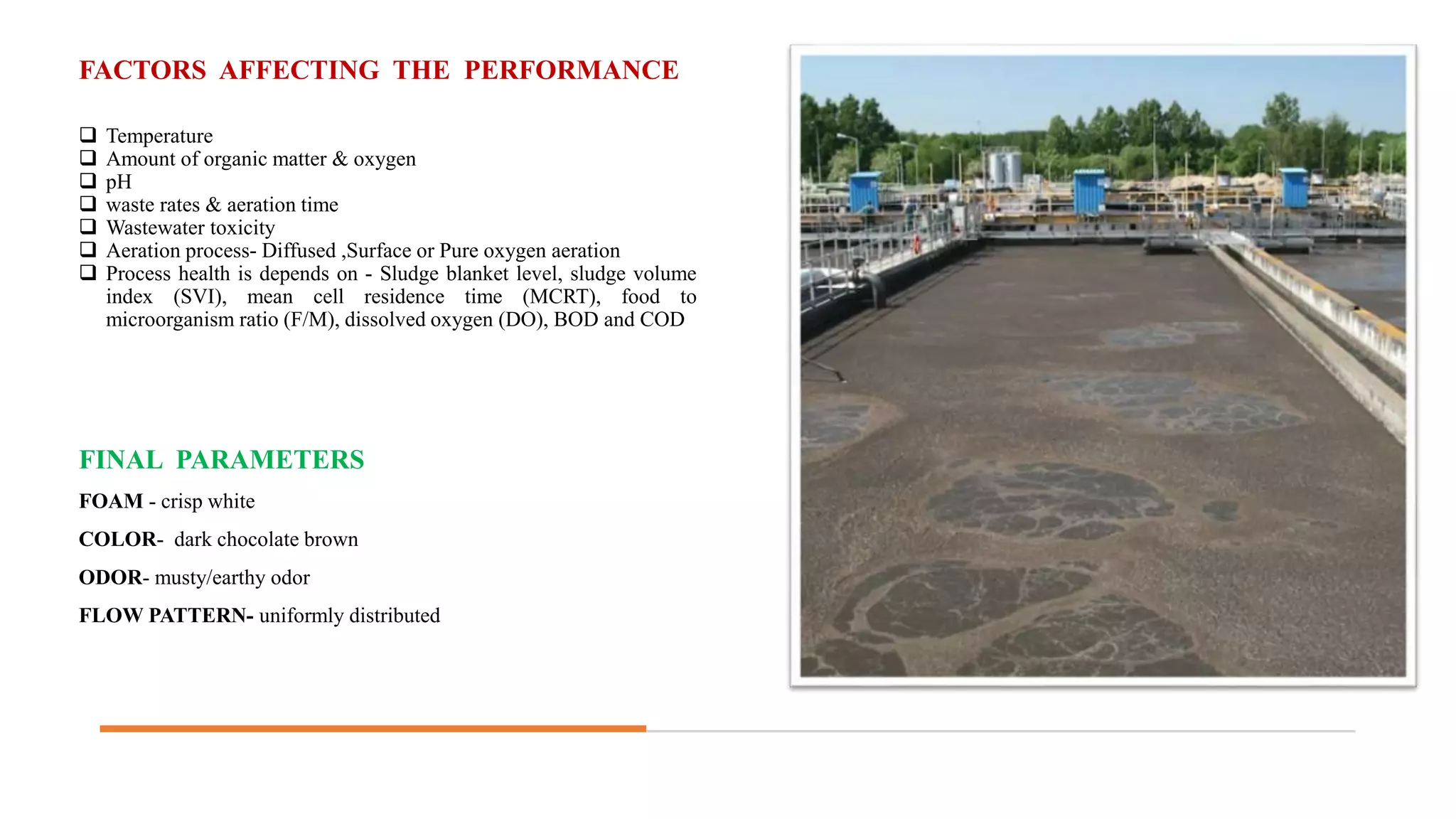

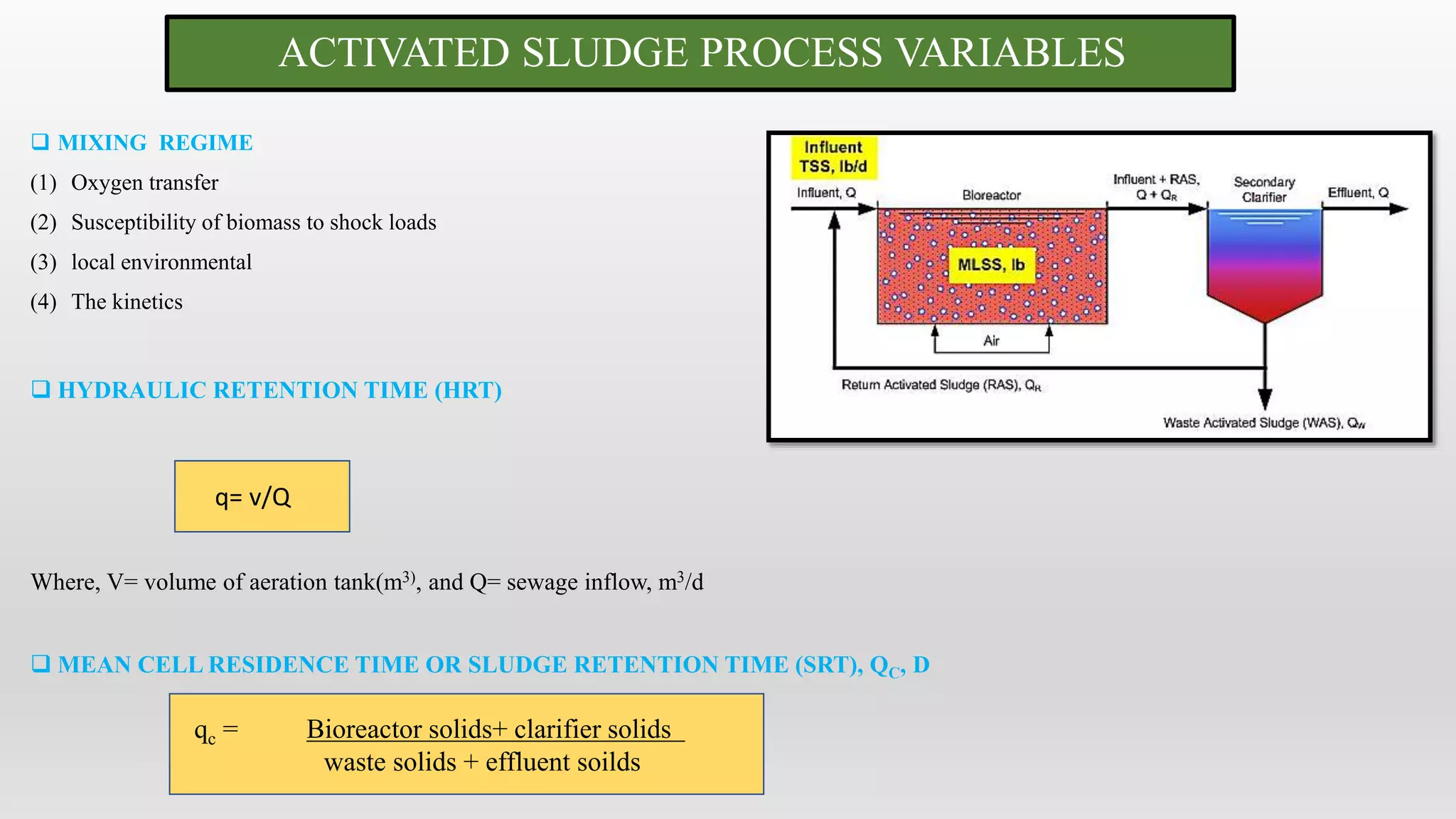

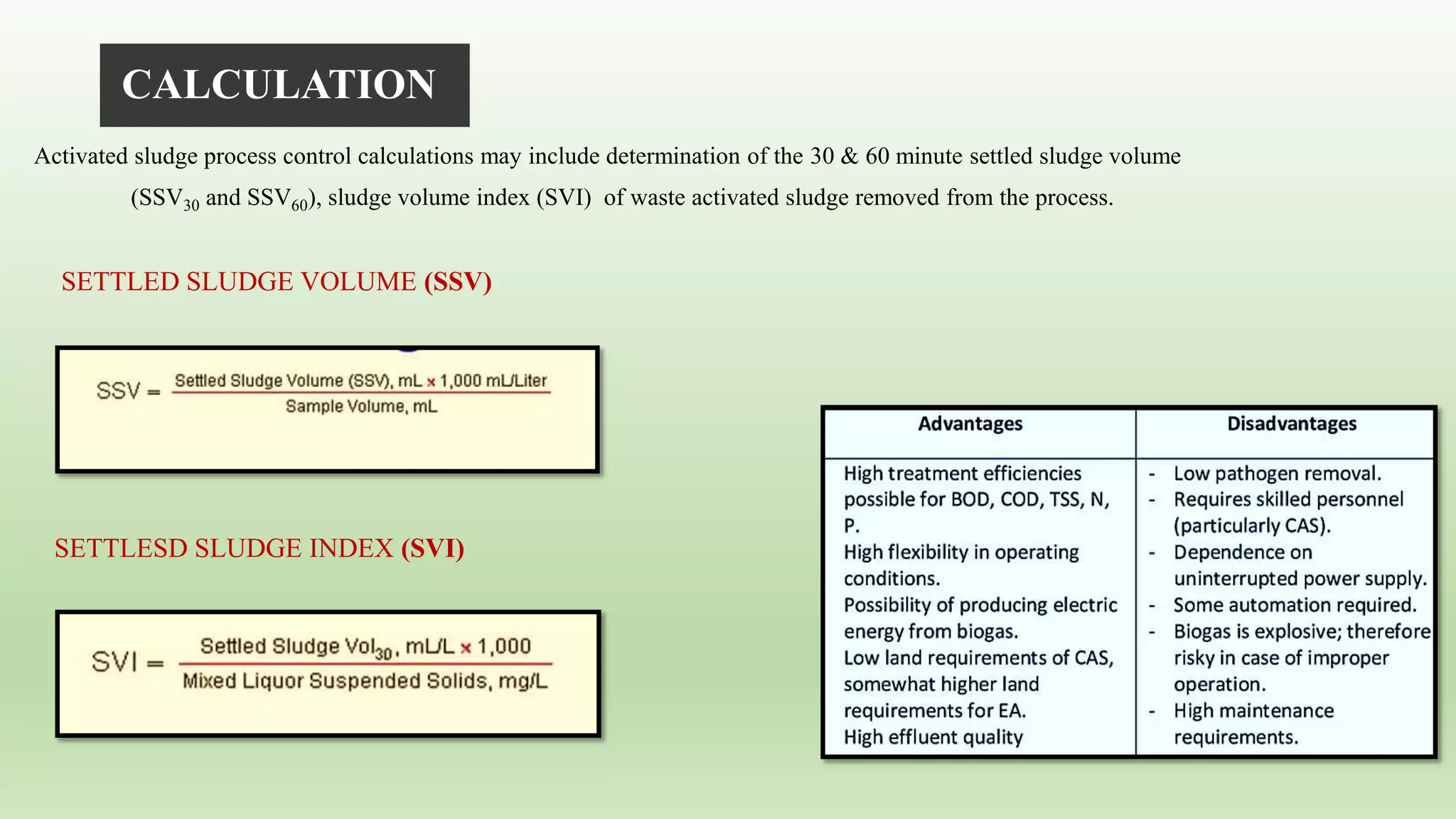

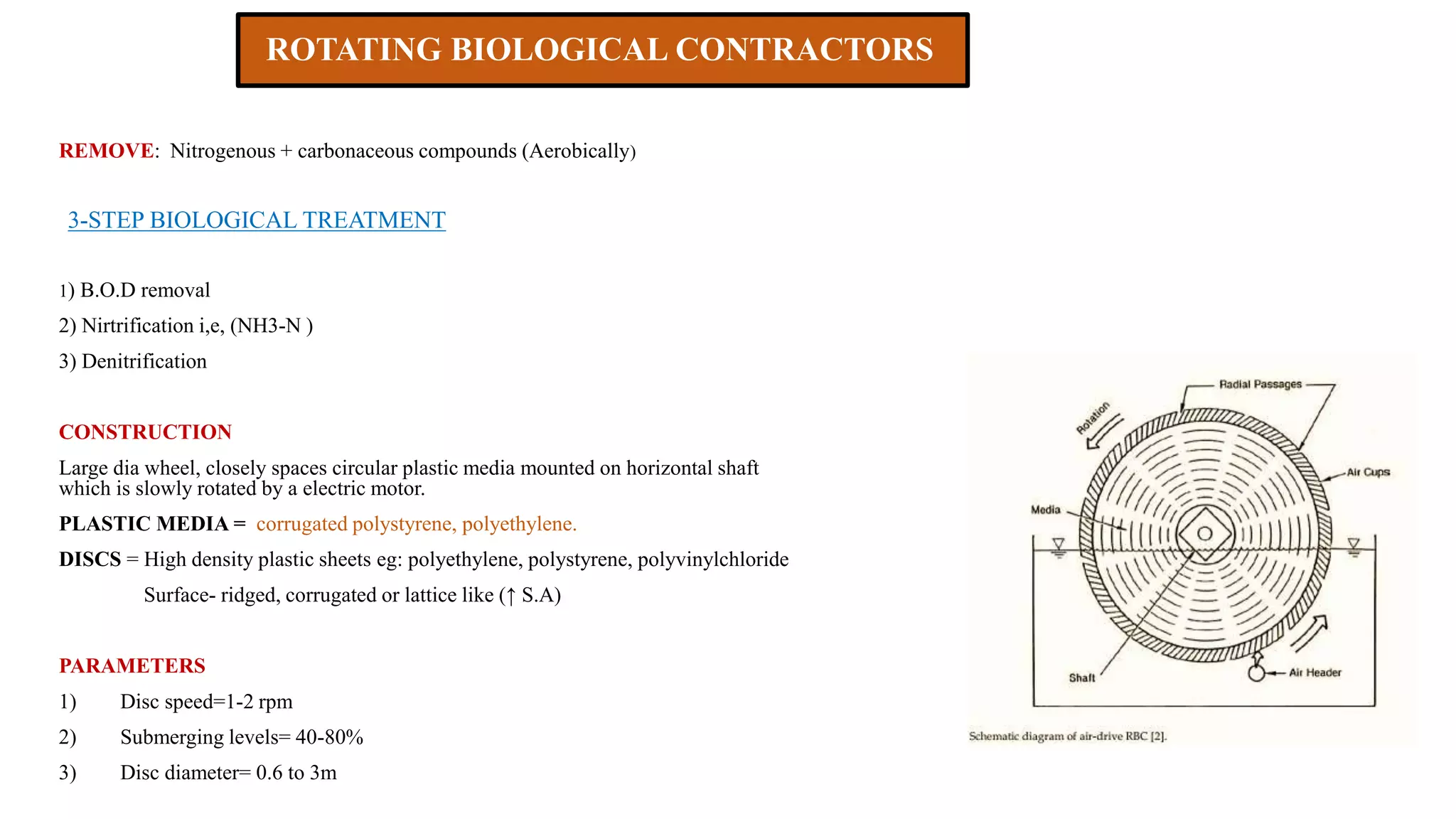

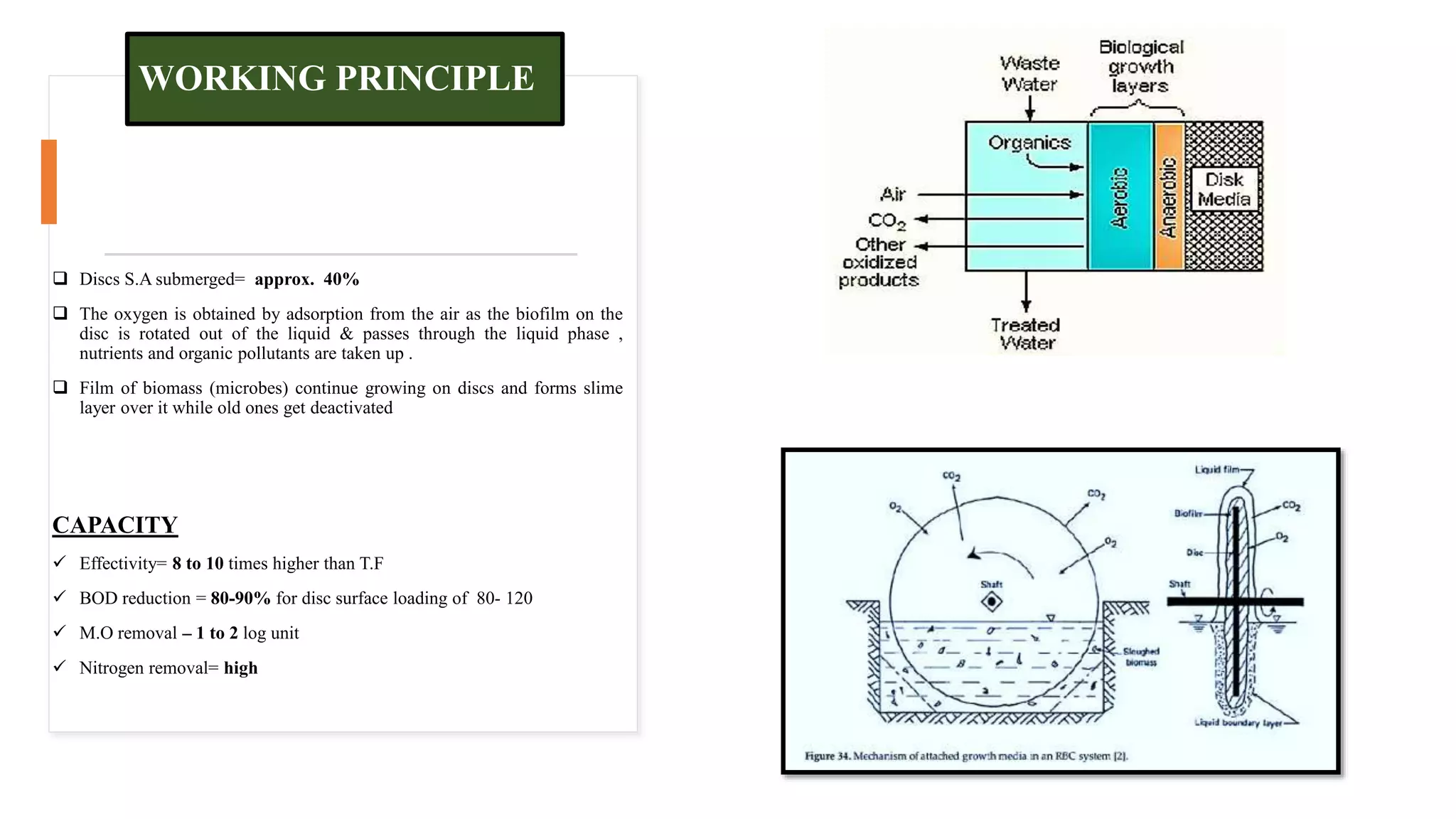

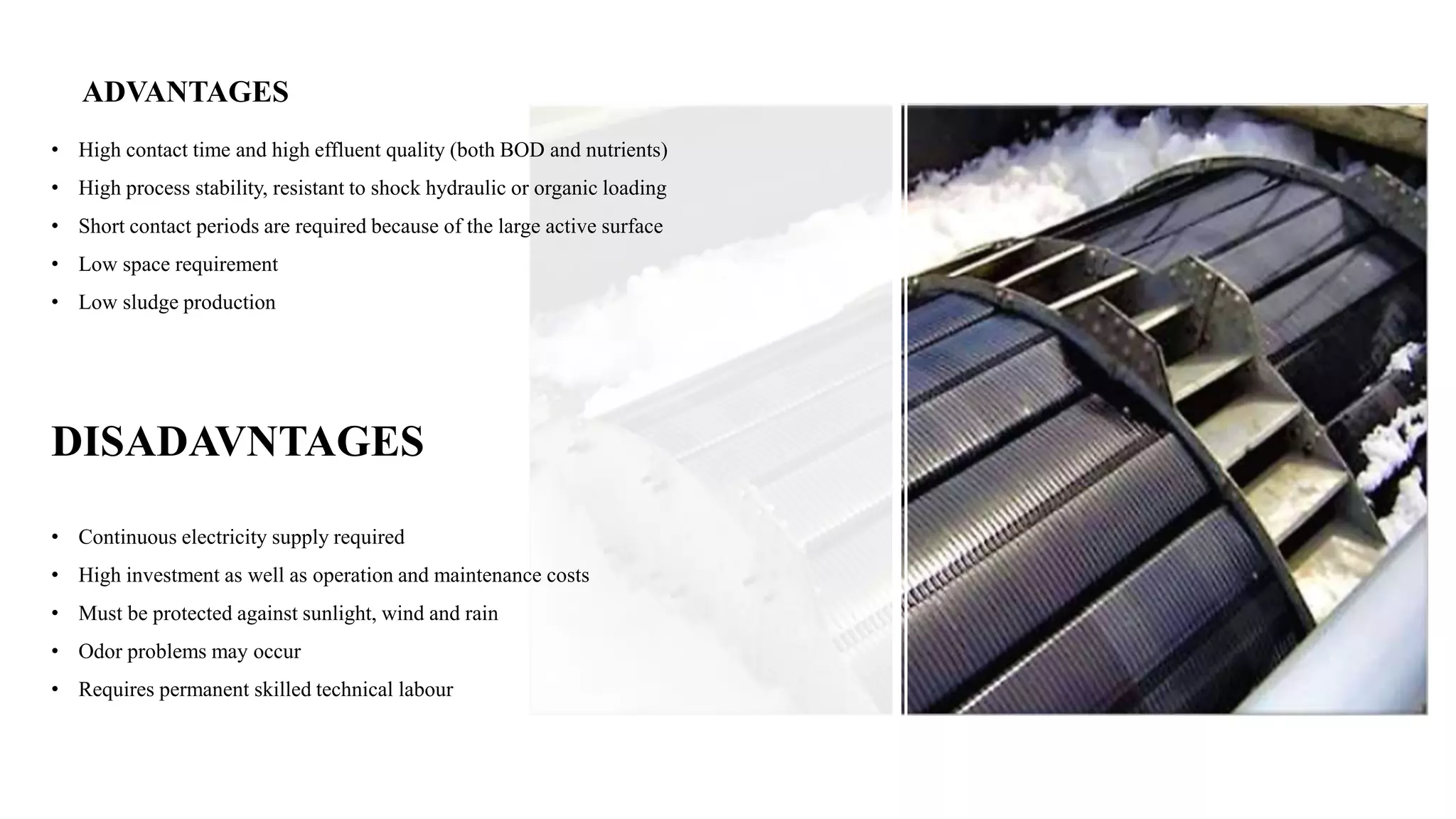

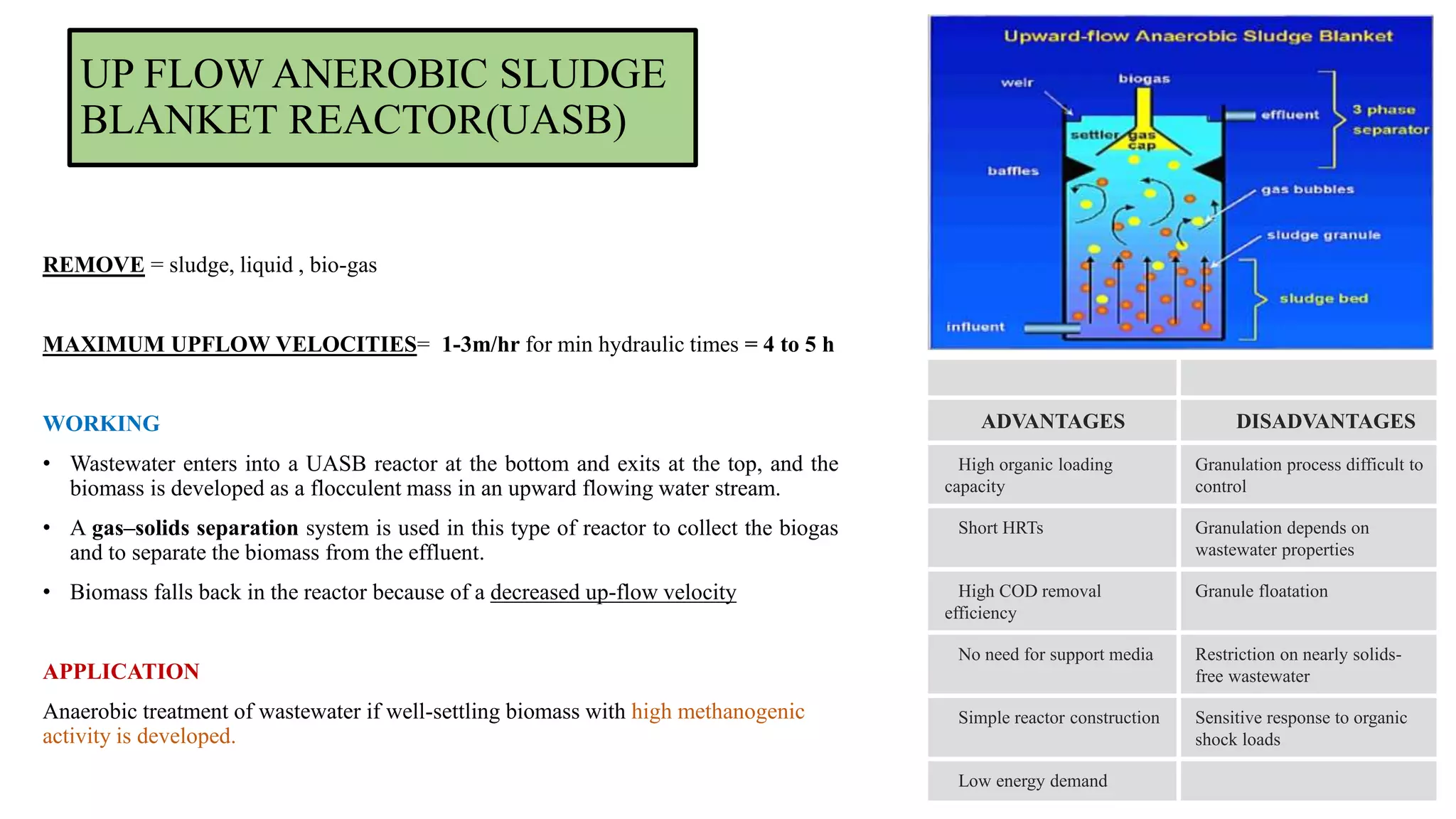

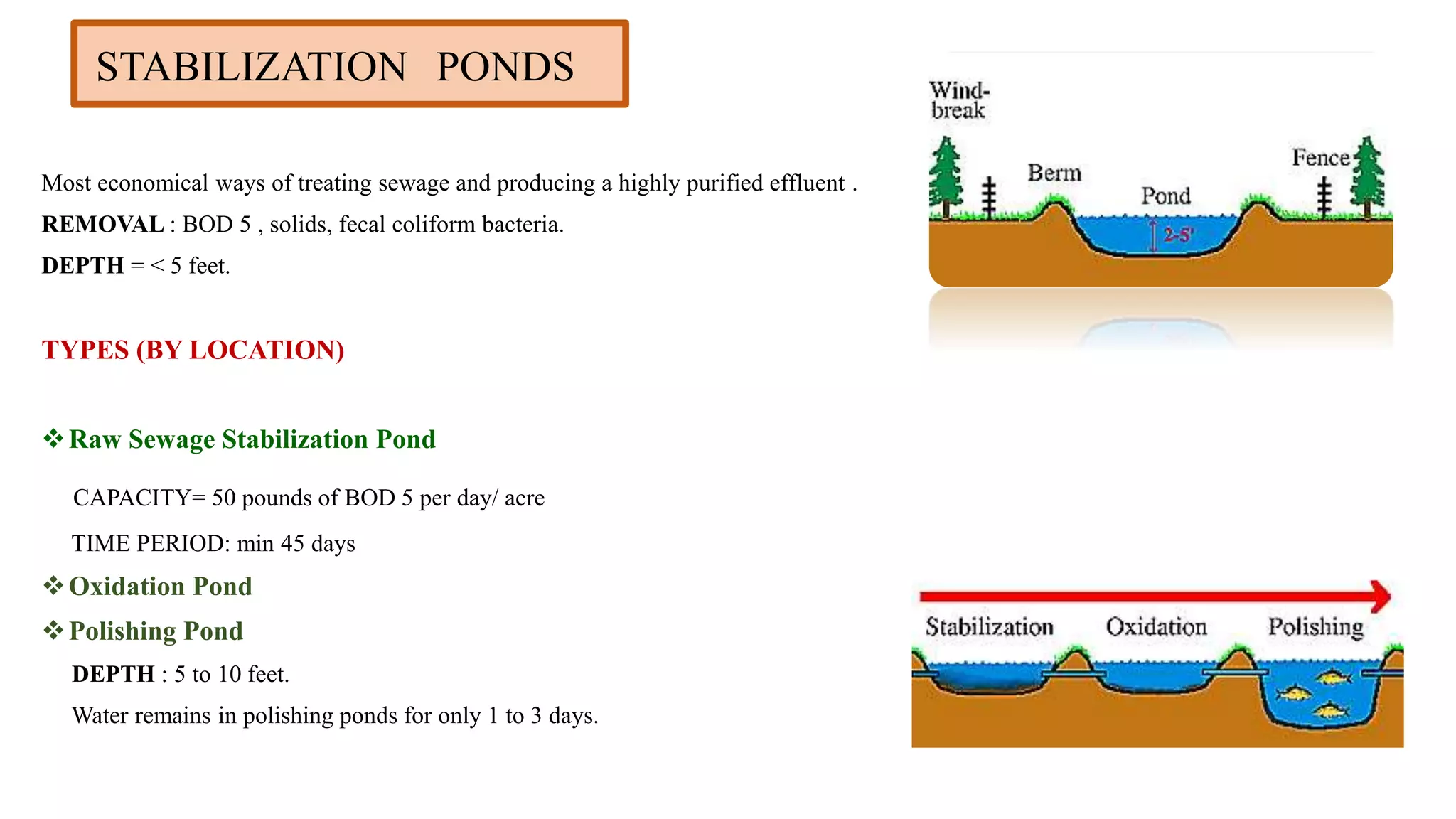

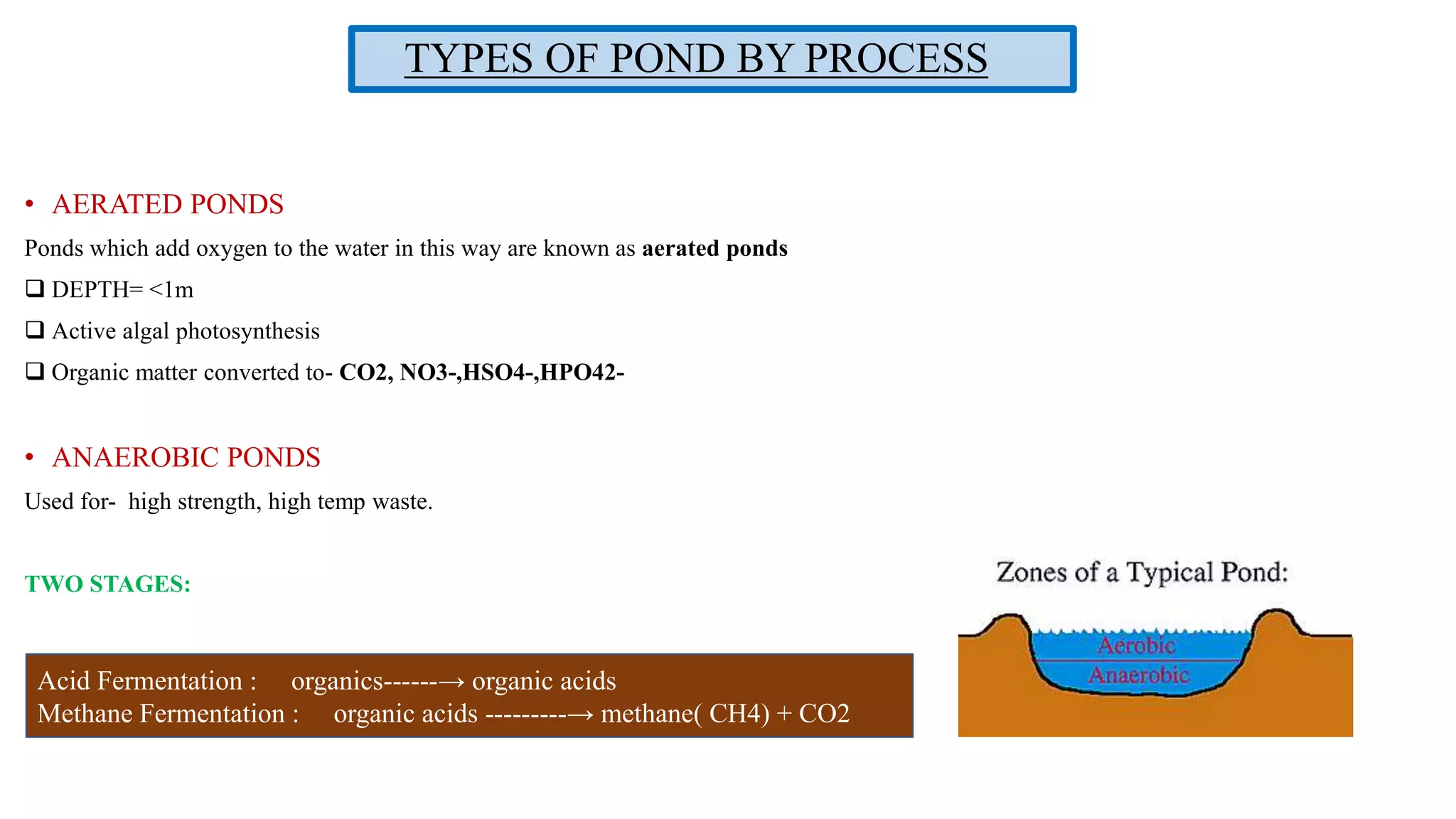

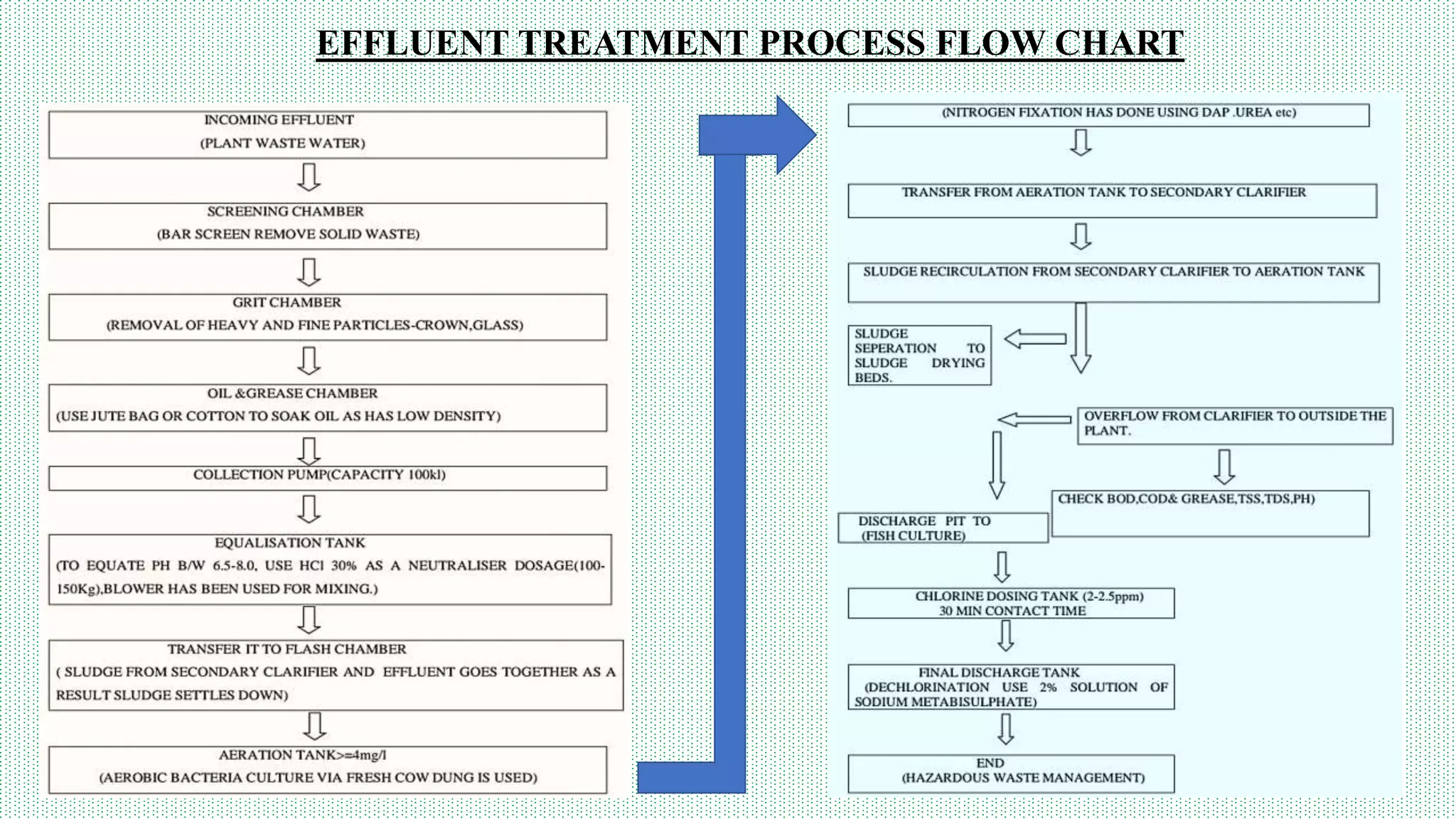

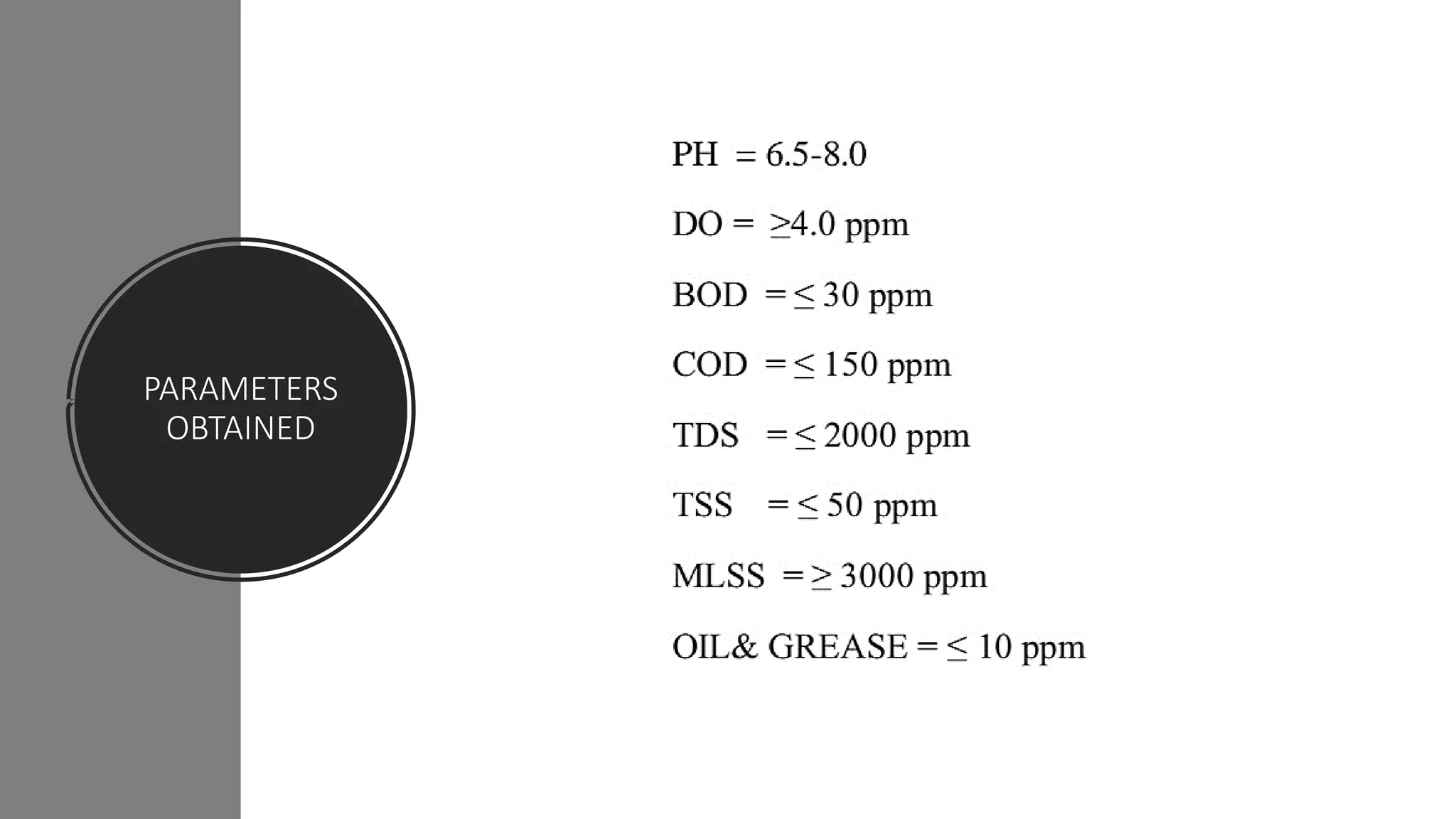

The document discusses various biological methods for waste disposal, including biological oxidation, biodegradation, and biosynthesis. It describes several treatment processes like activated sludge, trickling filters, rotating biological contractors, anaerobic digestion, and upflow anaerobic sludge blanket reactors. The key factors and working principles of each process are explained along with their advantages and disadvantages. Calculations for process variables like hydraulic retention time, organic loading rate, and sludge volume index are also presented.