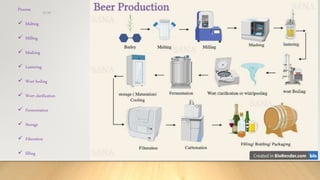

The document outlines the process of beer production, beginning with malting barley to release starch. The starch is mashed with water to produce wort, which is boiled with hops added for bitterness, aroma, and sterilization. The wort is fermented with yeast to produce alcohol, then stored, filtered, carbonated and packaged for distribution. Key steps include malting, mashing, lautering, wort boiling, fermentation, storage, filtration and filling. Hops provide bitterness from alpha acids and aroma from essential oils added at different boil stages.