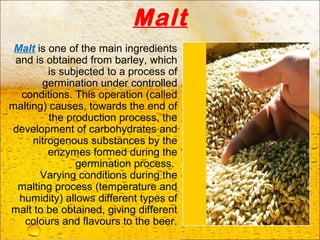

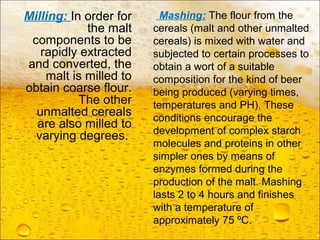

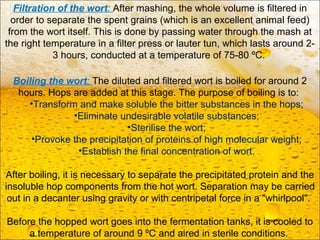

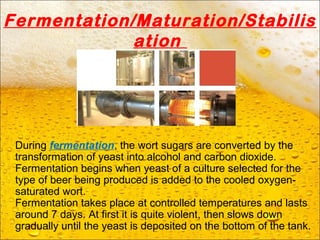

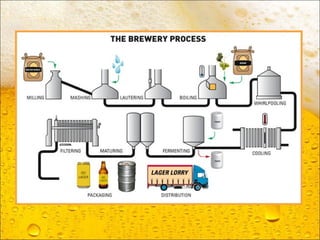

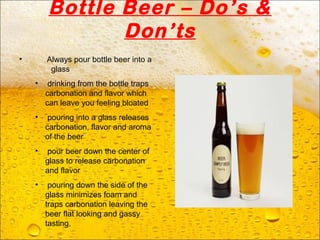

The document outlines the production of beer, detailing key raw materials like malt and hops, the brewing process which includes steps such as milling, mashing, and fermentation, and eventual bottling stages. It also discusses the impact of varying conditions on flavor and alcohol content, alongside opportunities and best practices for consumers. Overall, the document serves as a comprehensive guide to beer production from raw ingredients to finished product.