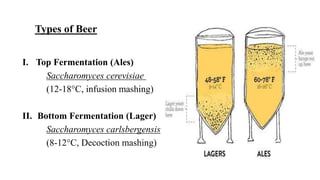

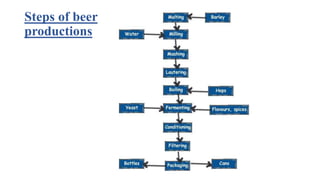

Beer is one of the oldest alcoholic beverages consumed by humans, dating back 7,000 years in China. It is made from water, malted barley, hops, and yeast. The production process involves malting, milling, mashing, lautering, boiling, fermenting, conditioning, filtering and packaging. Malting allows for conversion of starches to sugars, mashing extracts the sugars, boiling adds flavor and sterilizes, and fermentation converts sugars to alcohol and carbon dioxide using top or bottom fermenting yeast. The final product is filtered and packaged while excluding oxygen.