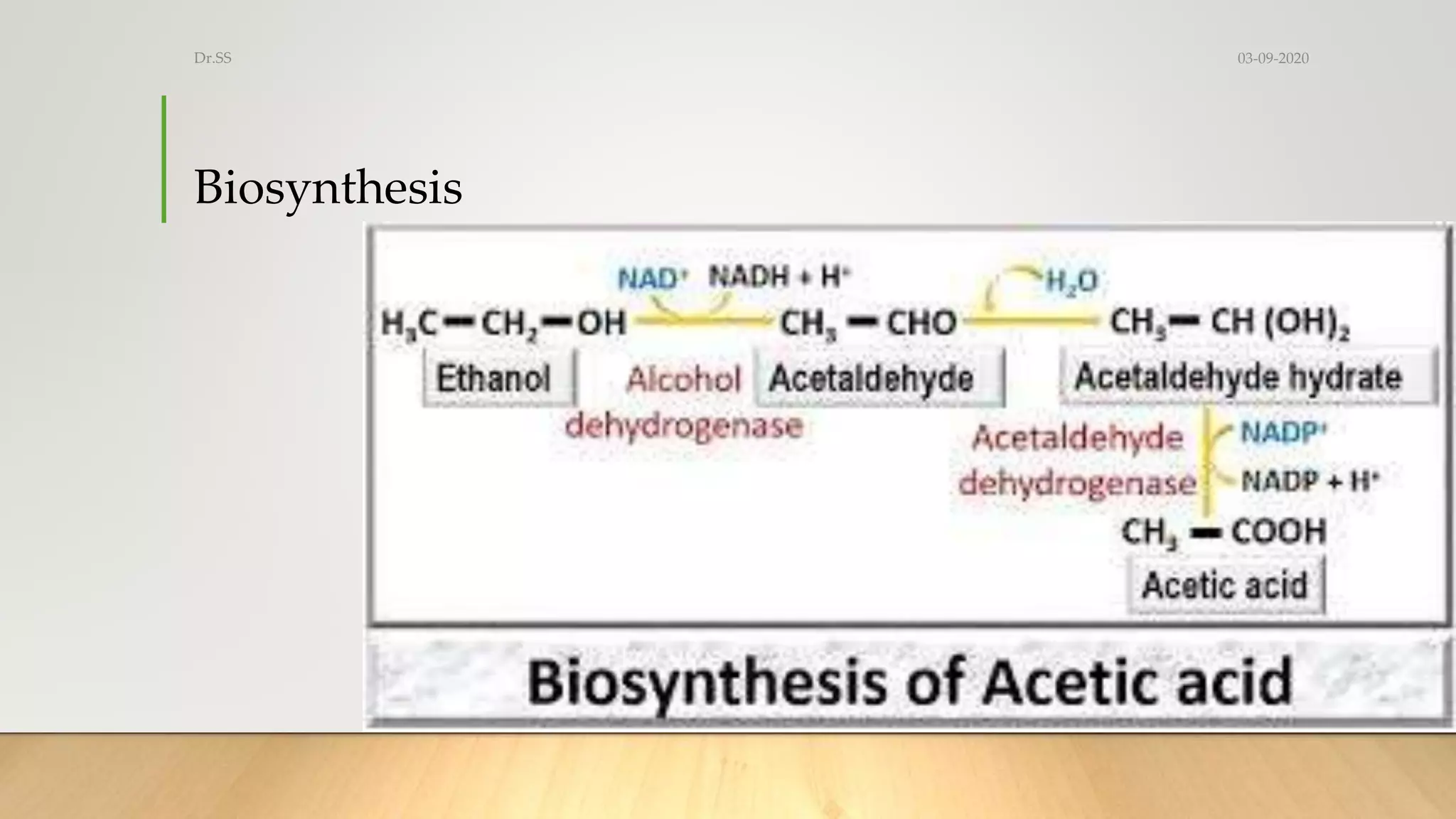

The document discusses the production of acetic acid. It describes the key steps in acetic acid production which include the conversion of starch to sugar, ethanol fermentation, conversion of ethanol to acetaldehyde, and finally the production of acetic acid. The main microorganisms used are acetic acid bacteria such as Acetobacter aceti. Three main methods of production are described - Orleans, surface fermentation, and submerged fermentation. The document also outlines applications and uses of acetic acid.