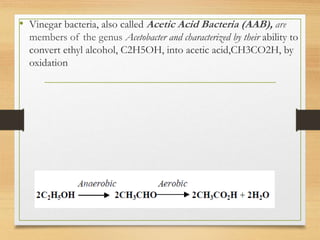

This document discusses vinegar production, detailing its definition, history, and various types, including their uses and production methods. It explains the fermentation process, the role of acetic acid bacteria, and specific methods like submerged and generator processes used in commercial production. The document also touches on vinegar's applications in medicine and its potential antitumor activity.