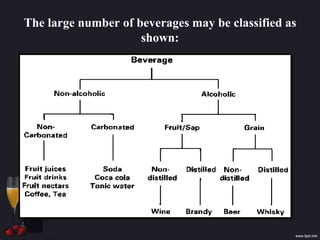

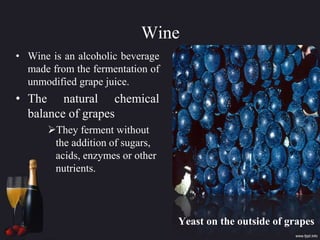

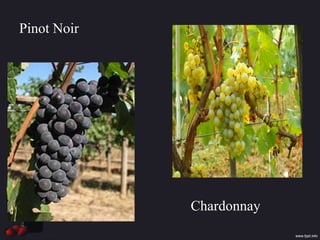

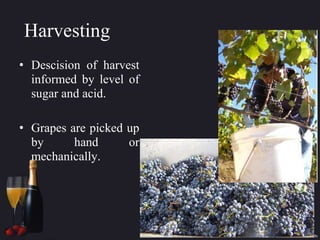

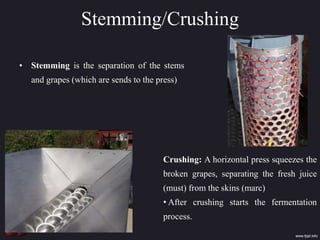

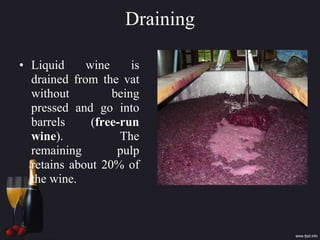

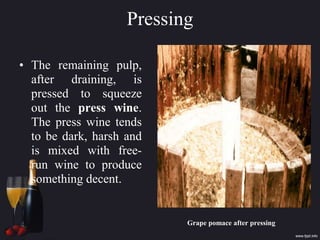

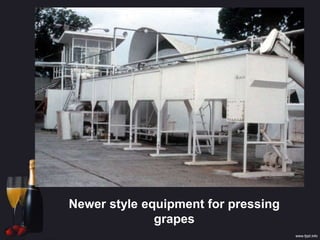

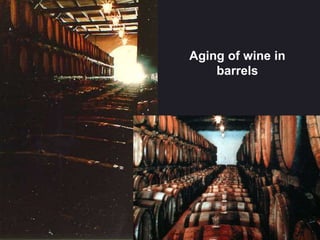

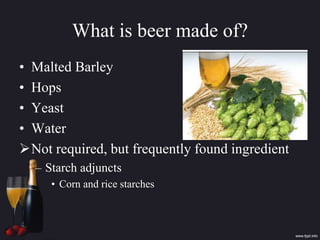

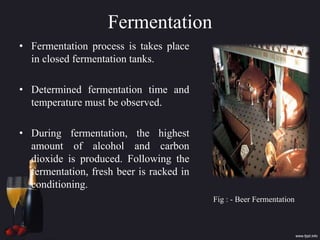

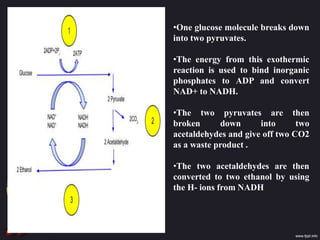

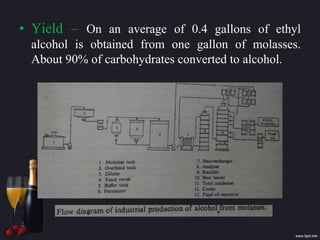

The document discusses various types of beverages, primarily focusing on alcoholic drinks such as wine and beer, along with their production processes. It details the steps involved in wine production, including harvesting, fermentation, aging, and bottling, as well as the brewing process of beer. It also explains the fermentation process for alcohol production, emphasizing the role of yeast and the necessary conditions for optimal yield.