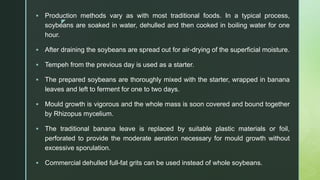

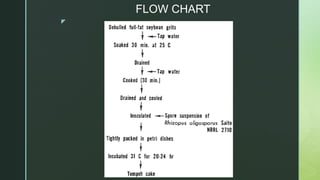

Tempeh is a fermented soybean product originating from Indonesia. It is made by fermenting cooked soybeans with Rhizopus moulds, resulting in a firm, compressed cake with a mild flavor. The traditional production process involves soaking, dehulling, cooking, and mixing soybeans with tempeh starter before wrapping and incubating to allow mould growth. Fermentation increases nutrients and breaks down compounds causing flatulence. Tempeh production is still predominantly small-scale in Indonesia and Malaysia, but it has spread to other countries and can now be produced industrially using stainless steel equipment and pure mould cultures.