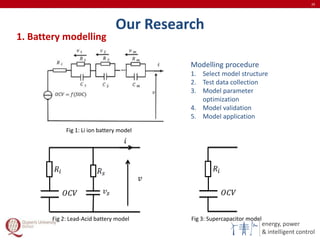

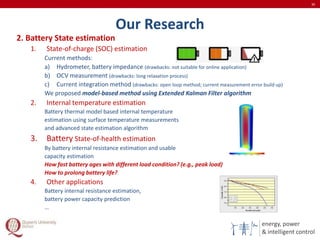

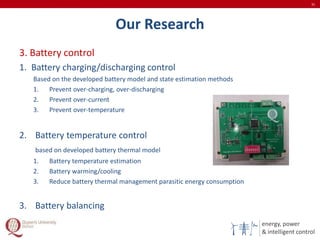

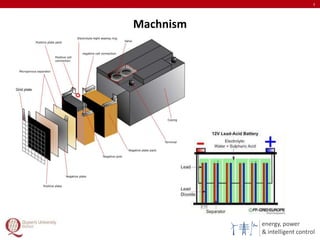

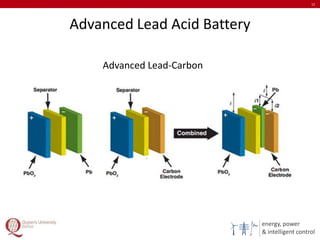

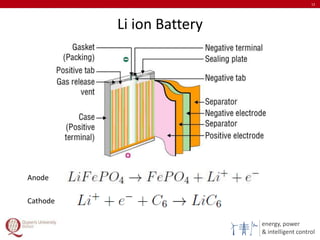

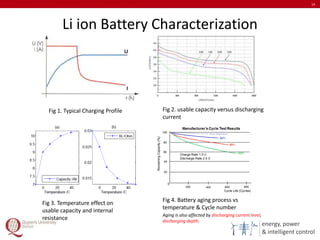

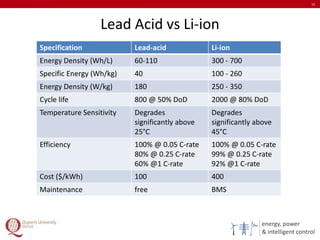

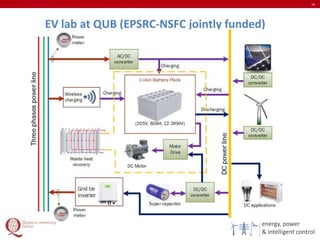

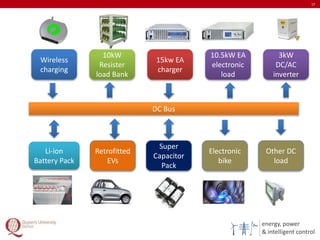

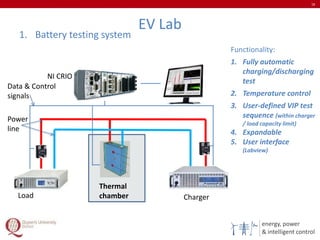

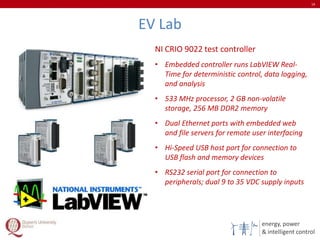

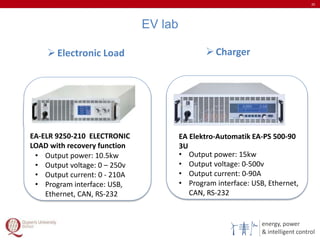

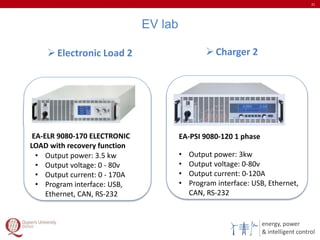

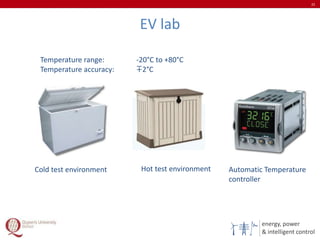

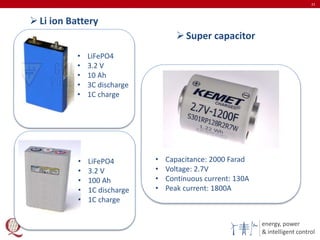

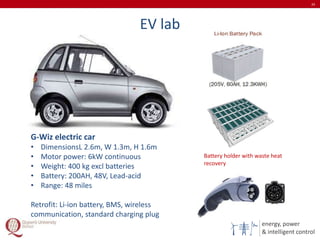

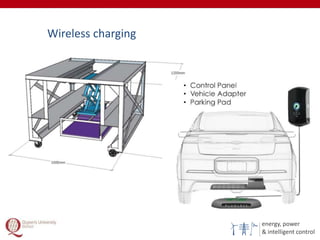

This document discusses battery technologies and the QUB EV lab. It provides information on lead-acid batteries, lithium-ion batteries, and supercapacitors. It describes the QUB EV lab facilities for battery testing including a thermal chamber, electronic loads and chargers. The lab conducts research on battery modeling, state estimation, control and applications to optimize battery performance and lifetime. It is available to support battery testing and analysis to help improve system designs.

![energy, power

& intelligent control

Test data

HPPC tests at different temperatures:

[0, 10, 23, 32, 39, 52]℃

Thermal test](https://image.slidesharecdn.com/batteryreportforkang-1-160226102313/85/Battery-report-FirstGroup-28-320.jpg)