The document discusses lead-acid batteries, including their components, electrolyte, charging methods, and testing. It provides details on:

- The three main functions of a battery in a vehicle's electrical system.

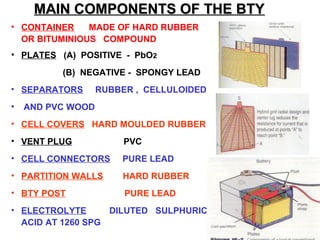

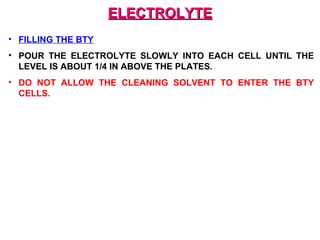

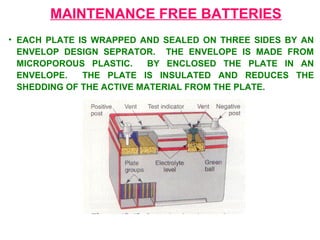

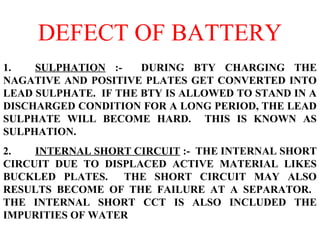

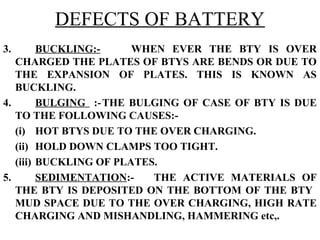

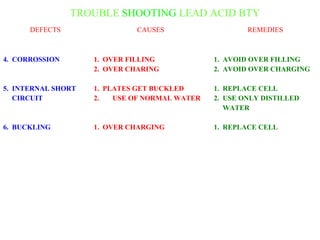

- The components of a battery, including plates, separators, cell covers, and electrolyte.

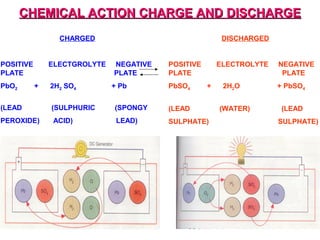

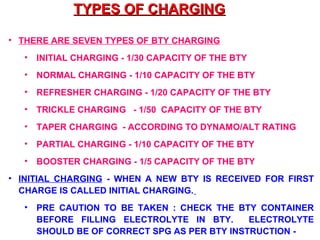

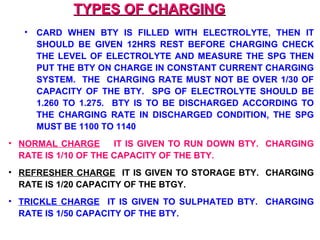

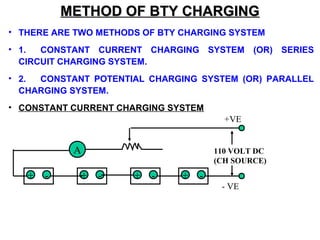

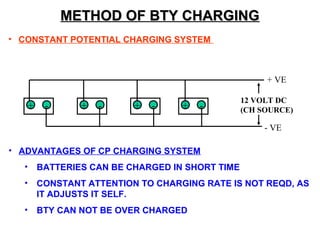

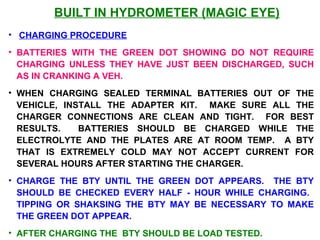

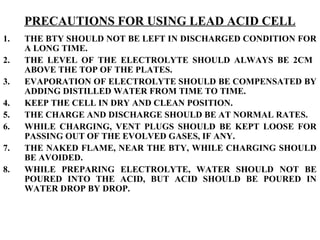

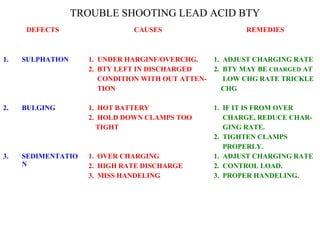

- Methods of charging batteries, including initial charging, normal charging, and trickle charging.

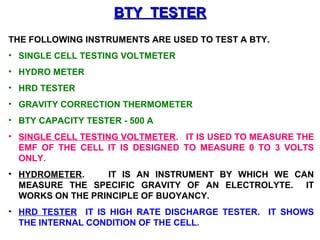

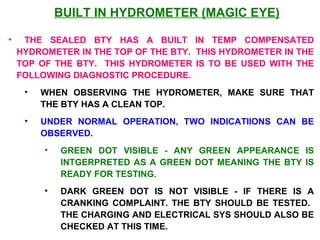

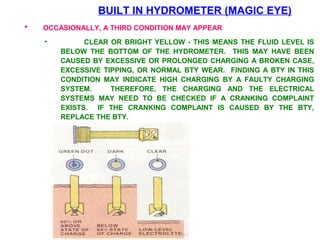

- Instruments used to test batteries, such as hydrometers and load testers.

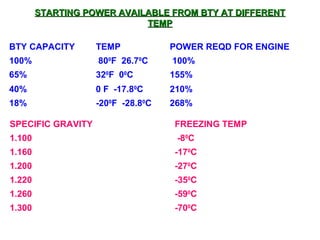

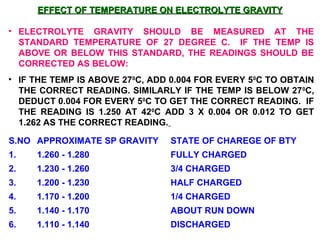

- Factors that affect battery capacity and performance, including temperature, age, and charging/discharging rates.