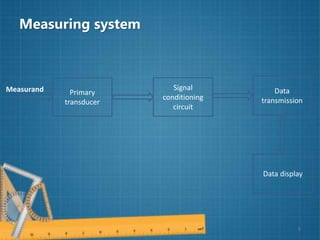

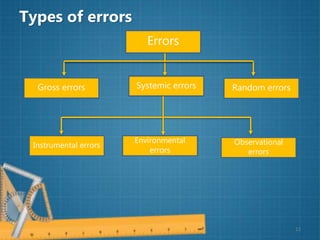

The document discusses measurement concepts, focusing on standard inputs, characteristics of measuring instruments, sources and types of measurement errors, as well as the importance of calibration. It highlights the need for accurate and precise measurements, explaining various error types including gross, systemic, and random errors. The document serves as an overview for understanding the principles and importance of measurement in engineering contexts.