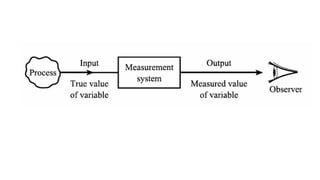

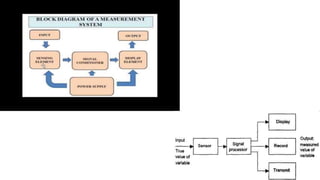

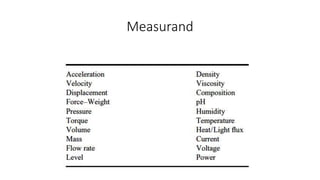

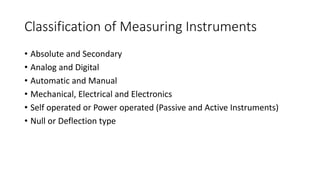

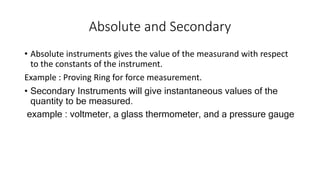

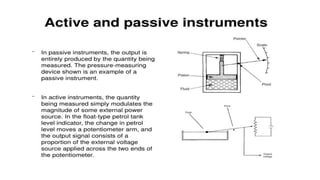

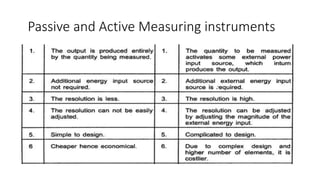

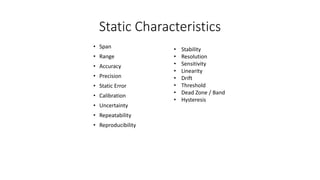

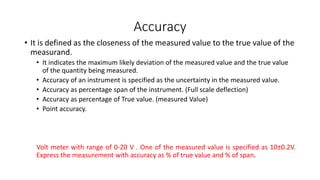

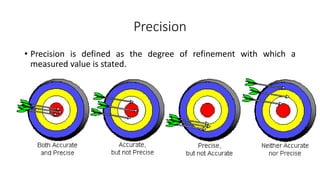

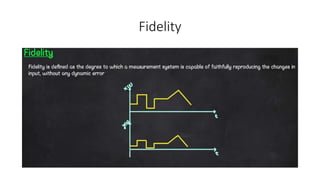

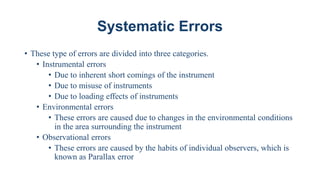

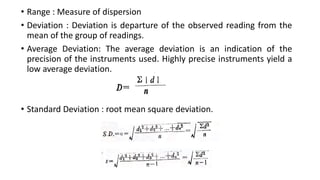

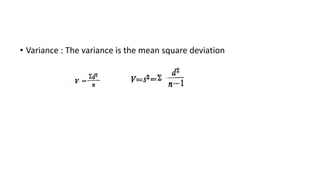

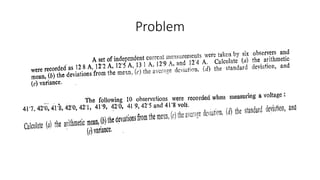

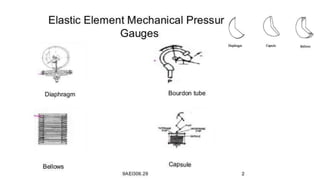

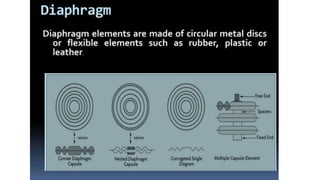

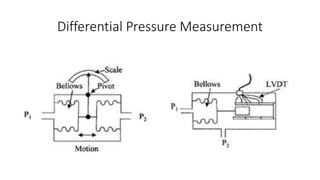

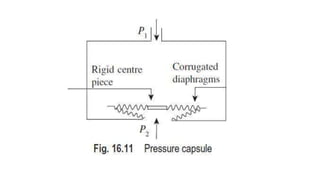

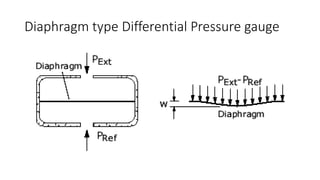

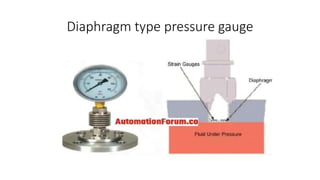

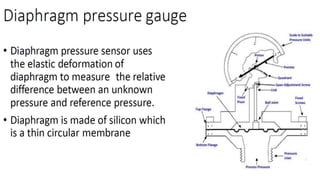

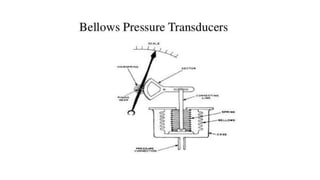

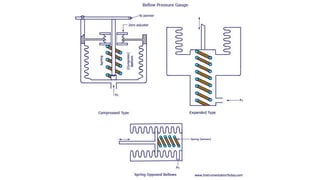

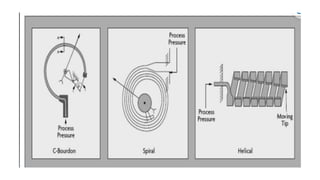

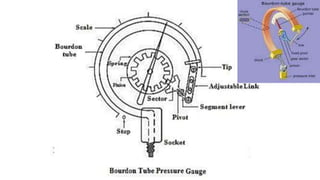

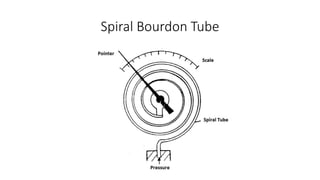

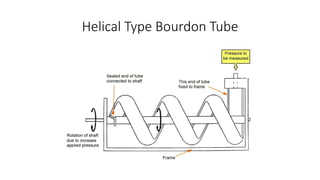

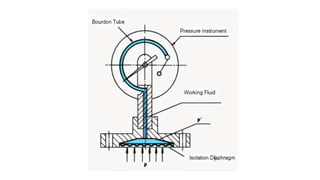

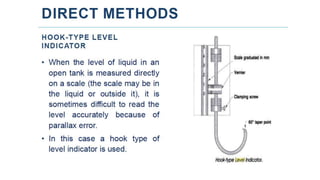

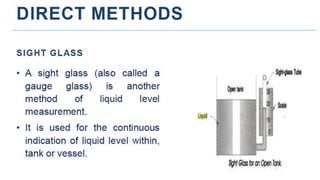

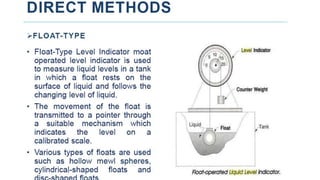

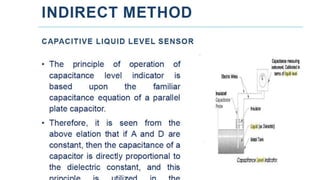

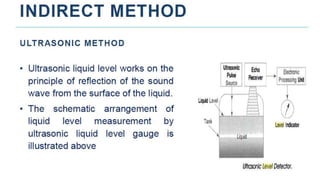

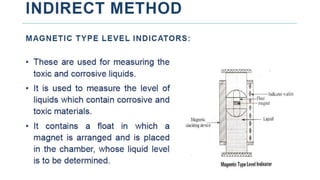

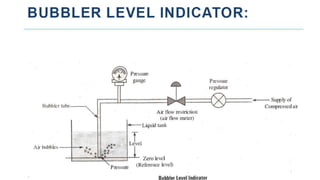

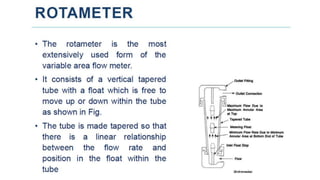

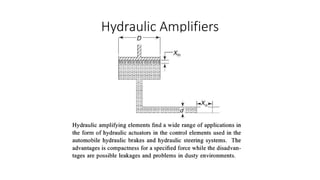

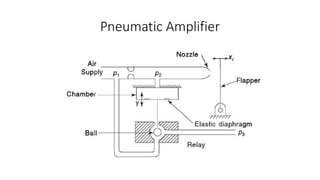

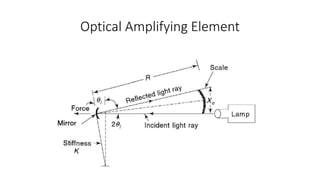

This document provides an overview of instrumentation and control engineering. It discusses fundamentals of measurement systems including instrument types, performance characteristics, sources of error, and statistical analysis of experimental data. It describes different types of measuring instruments and their characteristics such as accuracy, precision, calibration, uncertainty, and error. Examples of specific instruments are provided such as pressure gauges, differential pressure gauges, and liquid level measurement techniques. The document also discusses amplifiers used to increase sensor signals.