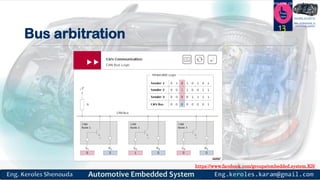

Controller Area Network (CAN) is a serial communication protocol that is most commonly used in automotive applications. It allows microcontrollers and devices to communicate with each other in real-time. CAN uses a multi-master broadcast communication style where nodes can transmit messages at any time and all nodes receive all messages. It uses priority-based arbitration to determine which message is transmitted when two nodes transmit simultaneously. CAN provides efficient, reliable, and economical communication between sensors, actuators and electronic control units in automotive and other embedded systems applications.

![https://www.facebook.com/groups/embedded.system.KS/

Follow us

Press

here

#LEARN_IN DEPTH

#Be_professional_in

embedded_system

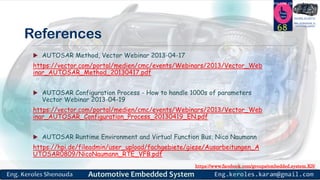

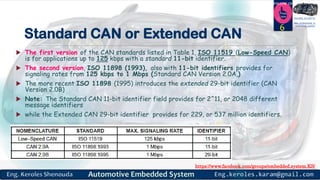

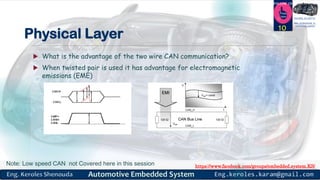

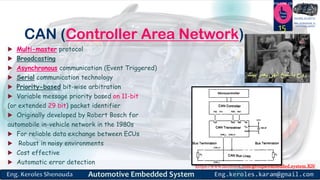

Bit Rate / Bus Length

1M bit/sec 40 meters (131 feet)

500K bit/sec 100 meters (328 feet)

250K bit/sec 200 meters (656 feet)

125K bit/sec 500 meters (1640 feet)

11

Bus lines

assumed to be

an electrical

medium

(e.g. twisted pair)

40 100 1000 10,000

CAN Bus Length [m]

0 10 200

1000

500

10

5

Bit Rate

[kbps]

20

50

200

100](https://image.slidesharecdn.com/automotiveembeddedsystemspart7v1-180403092053/85/Automotive-embedded-systems-part7-v1-11-320.jpg)

![https://www.facebook.com/groups/embedded.system.KS/

Follow us

Press

here

#LEARN_IN DEPTH

#Be_professional_in

embedded_system

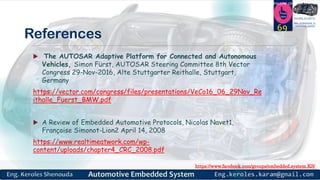

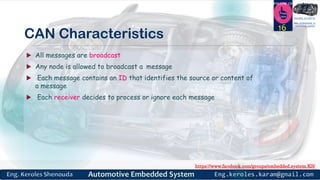

Data Flow in CAN

Transmitting Node

MCU Firmware

Identifier [id_n]

Data [values_x]

CAN Peripheral

Tx Mail Box [id_n]

Data [values_x]

Rx Mail Box [id_c]

Rx Mail Box [id_b]

CAN Transceiver

Node Configured to

receive identifier

MCU Firmware

Identifier [id_n]

Data [values_x]

CAN Peripheral

Data [values_x]

CAN Transceiver

Rx Mail Box [id_c]

Rx Mail Box [id_b]

Rx Mail Box [id_n]

Node not Configured to

receive identifier

MCU Firmware

CAN Peripheral

CAN Transceiver

Rx Mail Box [id_d]

Rx Mail Box [id_b]

Rx Mail Box [id_c]

Rx Mail Box [id_a]

Data Frame is broadcast to the bus ][value ]id n_[ x_

17](https://image.slidesharecdn.com/automotiveembeddedsystemspart7v1-180403092053/85/Automotive-embedded-systems-part7-v1-17-320.jpg)

![https://www.facebook.com/groups/embedded.system.KS/

Follow us

Press

here

#LEARN_IN DEPTH

#Be_professional_in

embedded_system

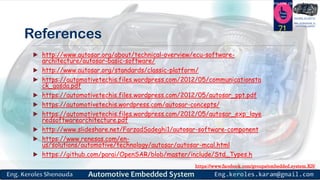

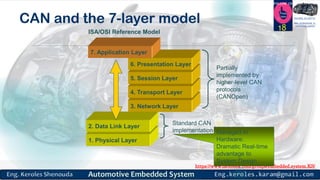

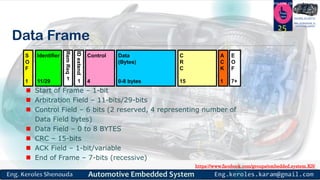

Start Of Frame [SOF]

SOF: CAN has a multi-master capability, meaning any node on the bus

can initiate communication to any node configured to receive. This is

done with a Start of Frame. A single dominant bit while the bus is idle

indicates a transmitting node is starting a frame.

All nodes on the bus will synchronize their bit timing to the leading

edge of SOF.

26](https://image.slidesharecdn.com/automotiveembeddedsystemspart7v1-180403092053/85/Automotive-embedded-systems-part7-v1-26-320.jpg)

![https://www.facebook.com/groups/embedded.system.KS/

Follow us

Press

here

#LEARN_IN DEPTH

#Be_professional_in

embedded_system

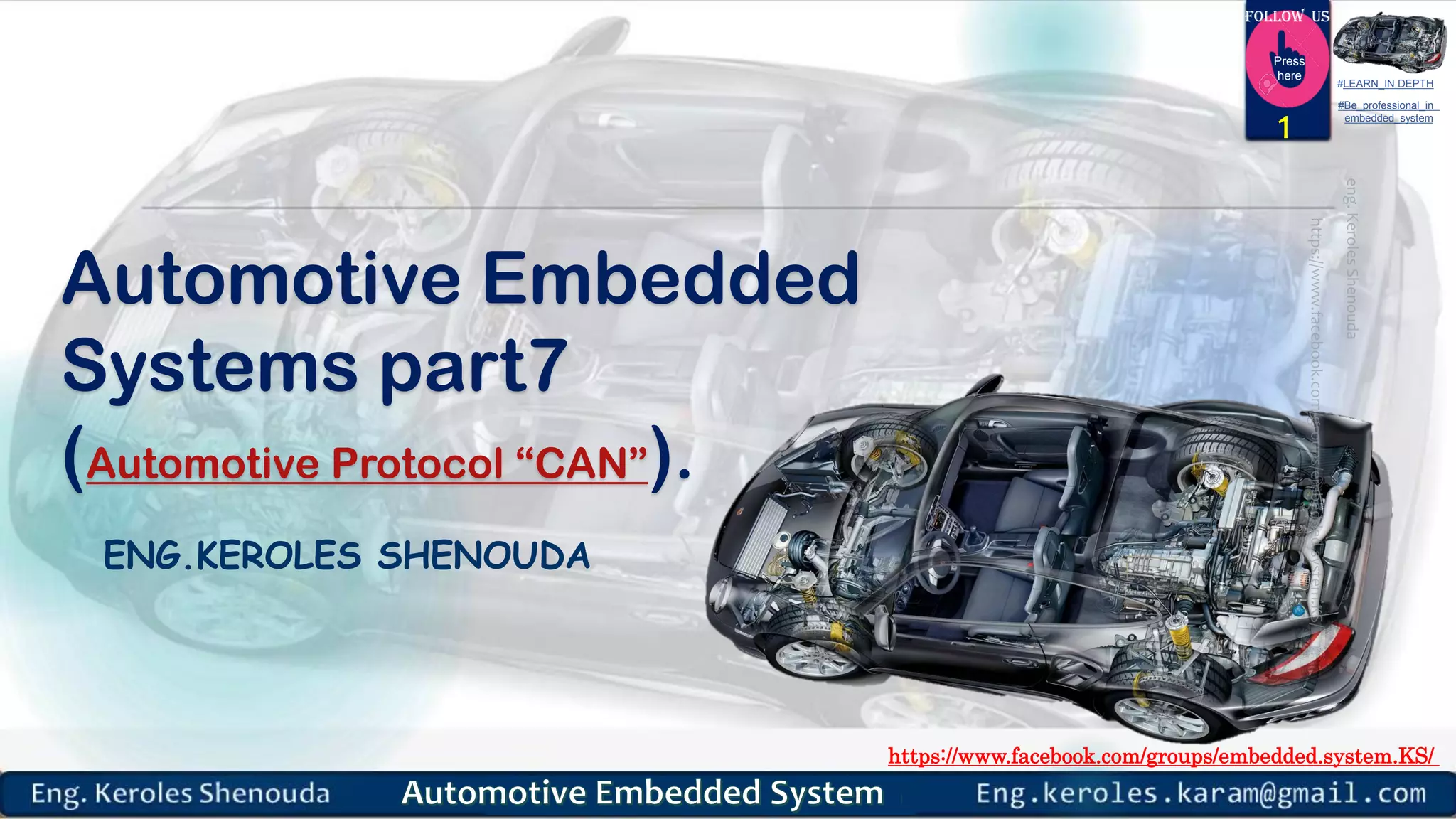

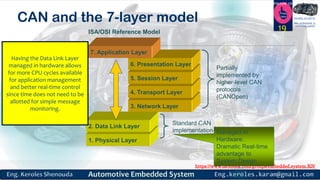

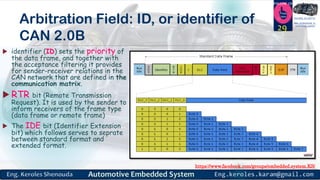

Control Field

The Control Field consists of six bits

- 1 are reserved

- 4 are the Data Length Code which indicates number of data bytes in

the data field [0-8 bytes being valid sizes]

- DLC codes not shown in the figure are reserved

30](https://image.slidesharecdn.com/automotiveembeddedsystemspart7v1-180403092053/85/Automotive-embedded-systems-part7-v1-30-320.jpg)