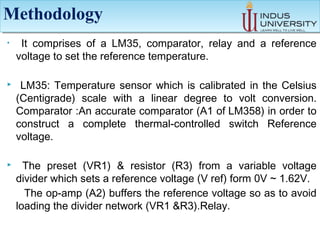

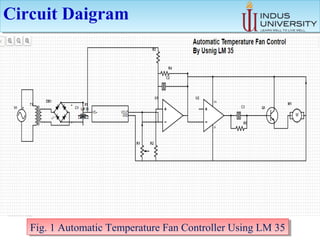

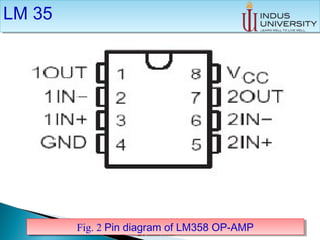

This project creates an automatic temperature fan controller using an LM35 temperature sensor, comparator, relay, and reference voltage. The circuit senses temperature and automatically controls a fan to keep the temperature within a set range. It was assembled, tested, and found to work satisfactorily by automatically turning the fan on or off based on temperature readings from the LM35 sensor.

![ [1]https://www.scribd.com/doc/110380630/Automatic-

Temperature-Controller-Using-Lm35

RefrencesRefrences](https://image.slidesharecdn.com/latiifffff2-180629222216/85/AUTOMATIC-TEMPERATURE-FAN-CONTROLLER-13-320.jpg)