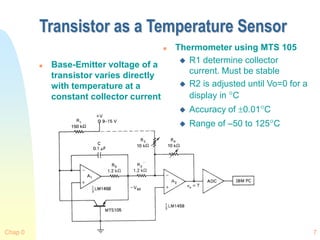

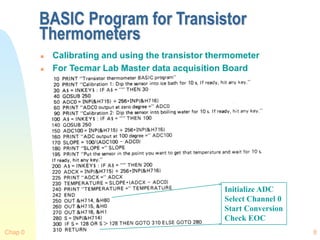

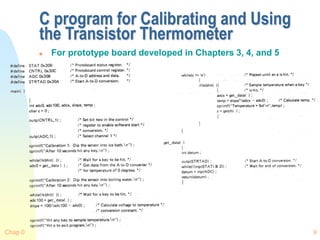

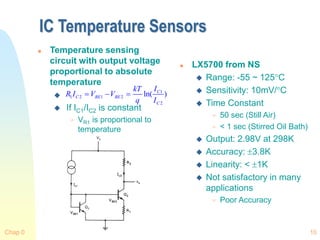

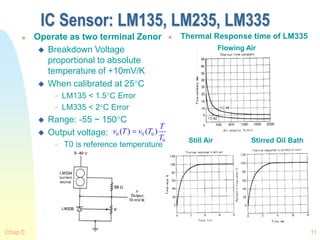

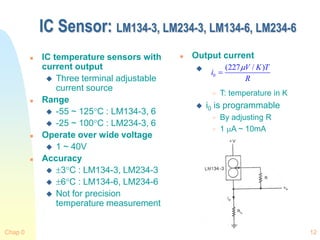

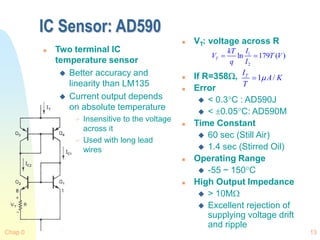

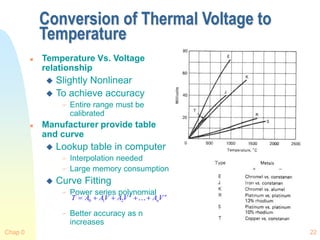

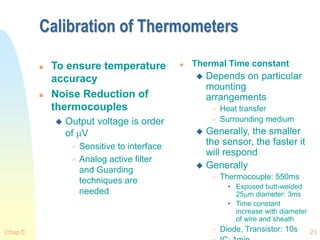

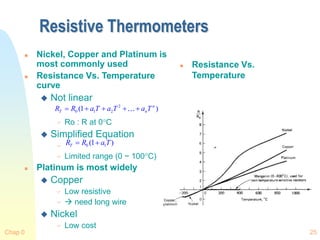

This document discusses various temperature sensing techniques including P-N junction thermometers, IC temperature sensors, thermocouples, and resistive temperature sensors. It provides details on the principles and applications of different types of temperature sensors like diode thermometers, transistor thermometers, IC sensors like LM135 and AD590, thermocouples, platinum resistance thermometers, and thermistors. The document also covers topics like calibration of thermometers, interfacing temperature sensors, and conversion of thermal voltage to temperature.

![Chap 0 4

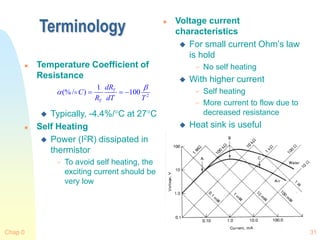

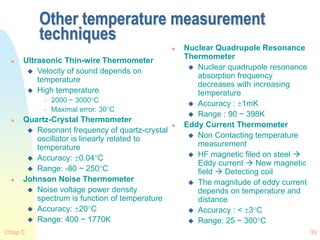

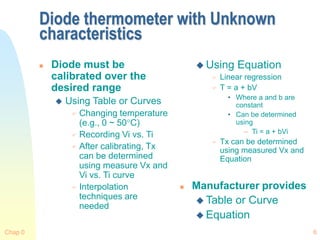

P-N Junction Thermometers

Principle of Diode

Thermometer

Forward Biased Current

Voltage

Where T is in K

Voltage vs. Temperature

Useful range

40 ~ 400K

[exp( ) 1]

2

s

qV

I I

kT

4.6

(ln ln )

g

E kT

V M I

q q

](https://image.slidesharecdn.com/7temperaturesensor-240302135949-70e3e6b9/85/7_Temperature_Sensor-ppt_ajinkya_xxxxxxxx-4-320.jpg)

![Chap 0 5

Diode thermometer with known

characteristics

Motorola MTS 105

Calibrate Diode to obtain

accurate output

Constant Current source

must be very stable

1C accuracy

0.002K with precision

GaAs Diode

Calibration Procedures

Determine VBE at

extremes (-40C and

150C)

Plot line using VBE(-40C) and

VBE(150C)

Given VBE(Tx), Tx can be found

using curve from step 2 or

equation

Diode are more sensitive and

linear than others

Wide range

Less repeatable

Affected by Magnetic (>

2.25 0.003( 600) /

c BE

T V mV C

[ ( ) (25 )]/ 25

x BE x BE c

T V T V C T

](https://image.slidesharecdn.com/7temperaturesensor-240302135949-70e3e6b9/85/7_Temperature_Sensor-ppt_ajinkya_xxxxxxxx-5-320.jpg)

![Chap 0 26

Platinum Thermometers

SPRT

Standard Platinum

Resistance

Thermometer

Range

13.81K ~ 903.89K

Some are designed to

1050C

Callendar-Van Dusen

Equation

-183 ~ 630C Range

Typically

0

3

[ (0.01 1)(0.01 )

(0.01 1)(0.01 ) ]

T

R R T T T

T T

1

0

0.00392

1.49

0( 0),0.11( 0)

100

C

T T

R

](https://image.slidesharecdn.com/7temperaturesensor-240302135949-70e3e6b9/85/7_Temperature_Sensor-ppt_ajinkya_xxxxxxxx-26-320.jpg)

![Chap 0 30

Empirical Correction

Basic Characteristics

Where

Ro : R at known To

• Usually 298.15K

: Material constant for

thermistor in K

• Determined from R

obtained at 0 and 50C

• 1500 ~ 6000K range

– Typically, 4000K

Few ~ 10M range

Steinhart-Hart Equation

Where

A, B, C are found by

solving three equations

with known R and T

Accuracy < 0.01C

More narrow range

-40C < T1, T2, T3 <150C,

|T2-T1|<50C, |T3-T2|<50C

0

0

1 1

exp[ ( )]

T

R R

T T

3

1

ln (ln )

A B R C R

T

1

ln

B

C

T R A

](https://image.slidesharecdn.com/7temperaturesensor-240302135949-70e3e6b9/85/7_Temperature_Sensor-ppt_ajinkya_xxxxxxxx-30-320.jpg)