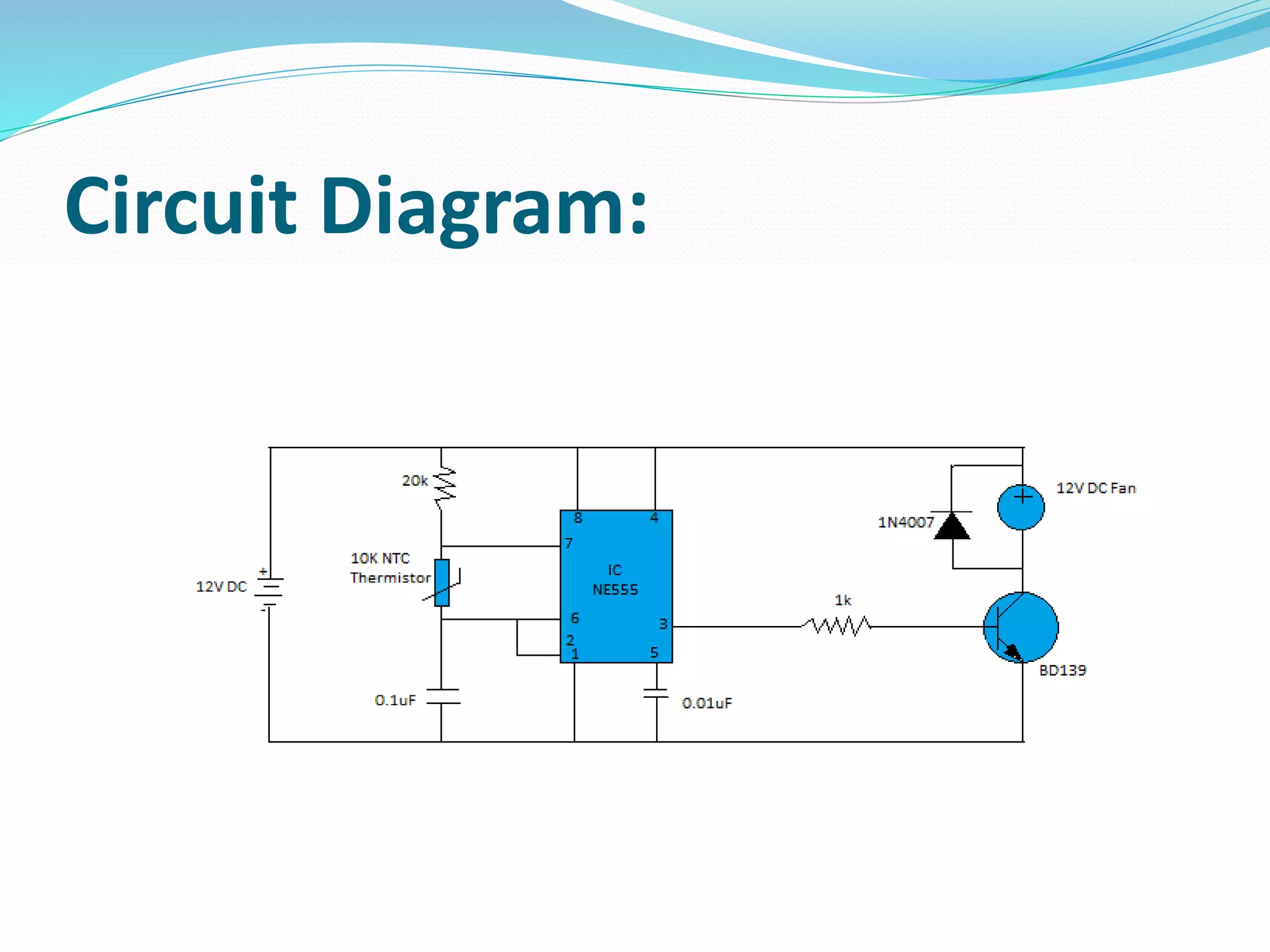

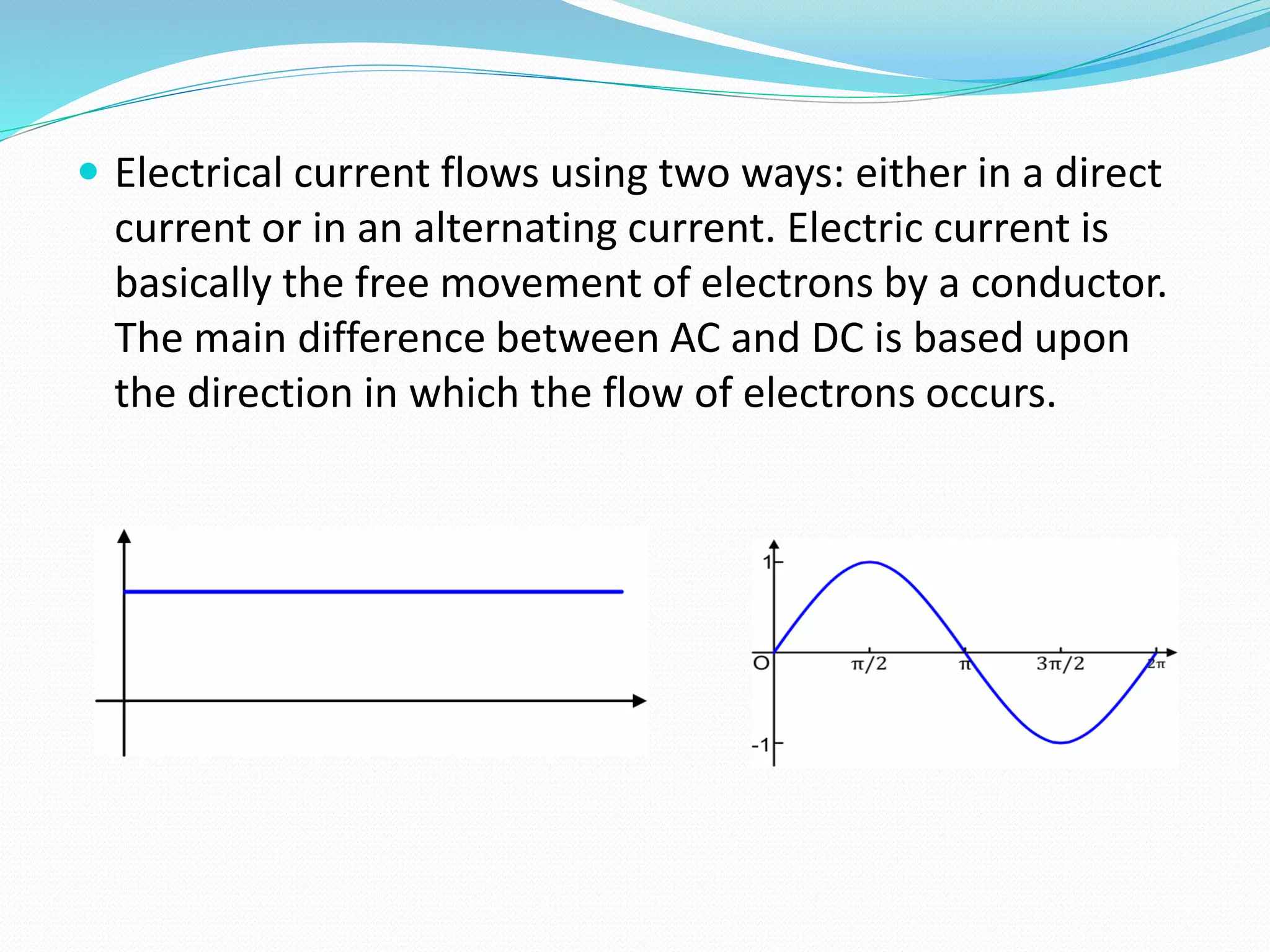

The document outlines a project on a temperature-controlled DC fan designed to operate automatically when surrounding temperatures exceed a preset level, utilizing components like an NTC thermistor and an NE555 IC. It explains the function and types of NTC thermistors, the characteristics of a DC battery, and the role of various electronic components in the circuit. The fan can serve applications such as cooling electronic devices and regulating car engine temperatures.