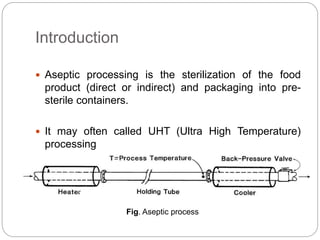

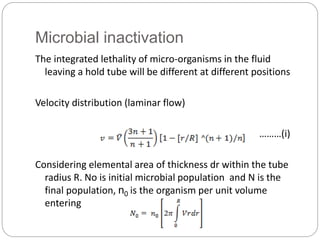

The document discusses aseptic processing, which involves sterilizing food products and packaging them into pre-sterile containers, often using ultra high temperature (UHT) methods. It explains the heat transfer process involved, using mathematical models such as the explicit finite difference method, and details microbial inactivation and nutrient degradation during the processing. Additionally, it describes how parameters like heat energy, velocity distribution, and initial microbial population impact the efficacy of the aseptic process.