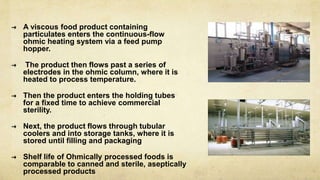

Ohmic heating is a method of heating food through the direct passage of alternating electric current. It allows for rapid and uniform heating of both liquids and particulate foods from the inside out. During ohmic heating, the food acts as an electrical resistor and generates heat when current is passed through it. This results in minimal thermal degradation compared to conventional surface heating methods. Some applications of ohmic heating include heating soups, juices and other liquid foods with particles.