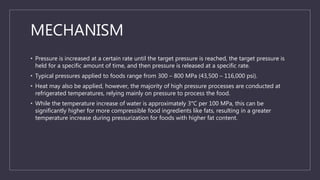

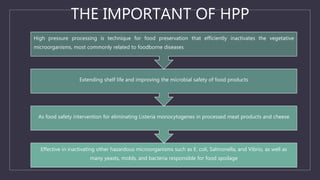

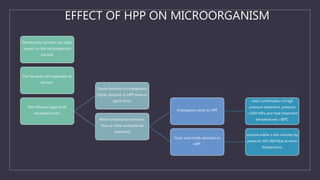

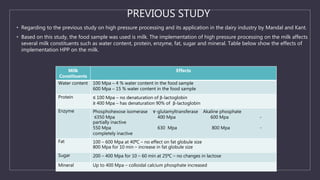

High Pressure Processing (HPP) is an alternative food preservation method that employs elevated pressure to inactivate microorganisms while maintaining food quality. HPP is effective against various pathogens, enhances shelf life, and preserves nutrient content, but requires expensive equipment and is primarily suited for refrigerated foods. Its applications span various food types, including meat, dairy, and beverages, demonstrating significant advantages over traditional thermal processing methods.