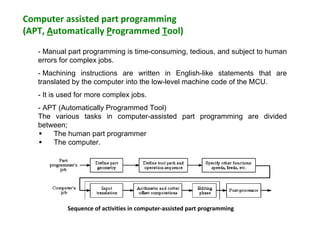

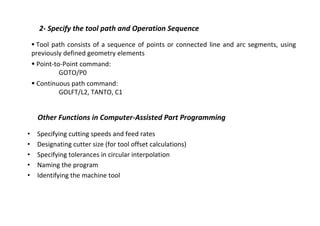

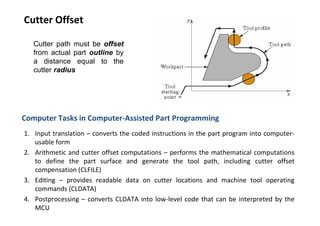

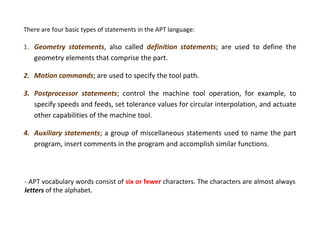

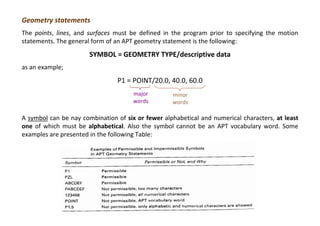

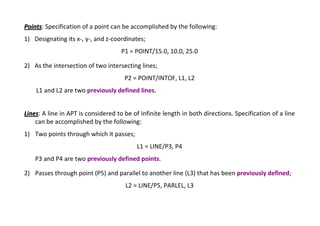

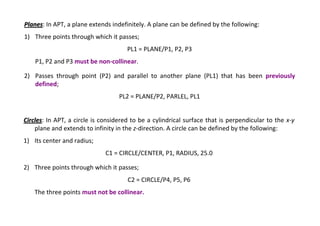

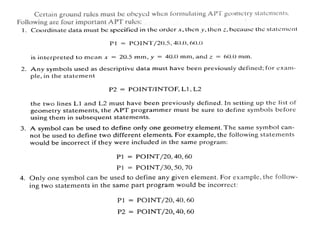

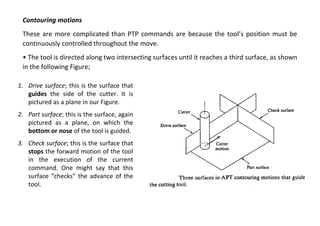

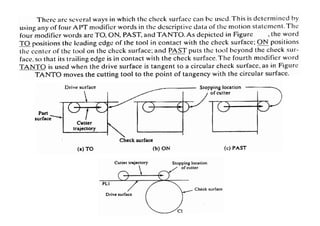

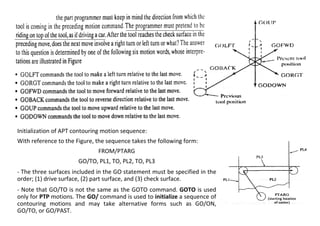

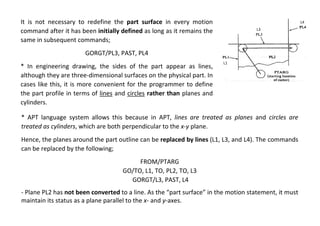

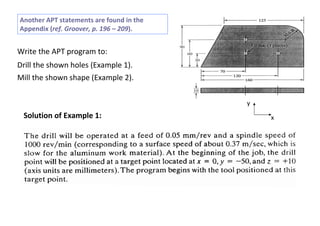

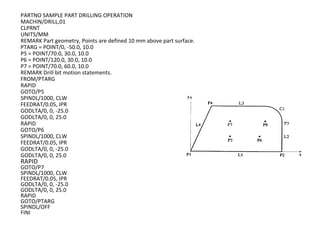

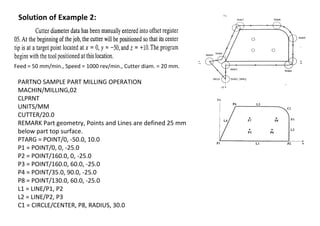

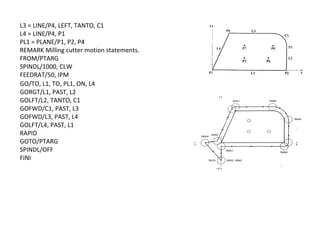

Computer assisted part programming uses APT language to define part geometry and tool paths to automate machining instructions. The programmer first defines points, lines and surfaces that make up the part geometry. They then specify the tool path using motion commands to guide the tool along the geometry. The computer translates these instructions into machine code for the machining center. It allows complex parts to be machined more efficiently by automating programming tasks and reducing errors.