This document provides information on Ingeo fiber, including:

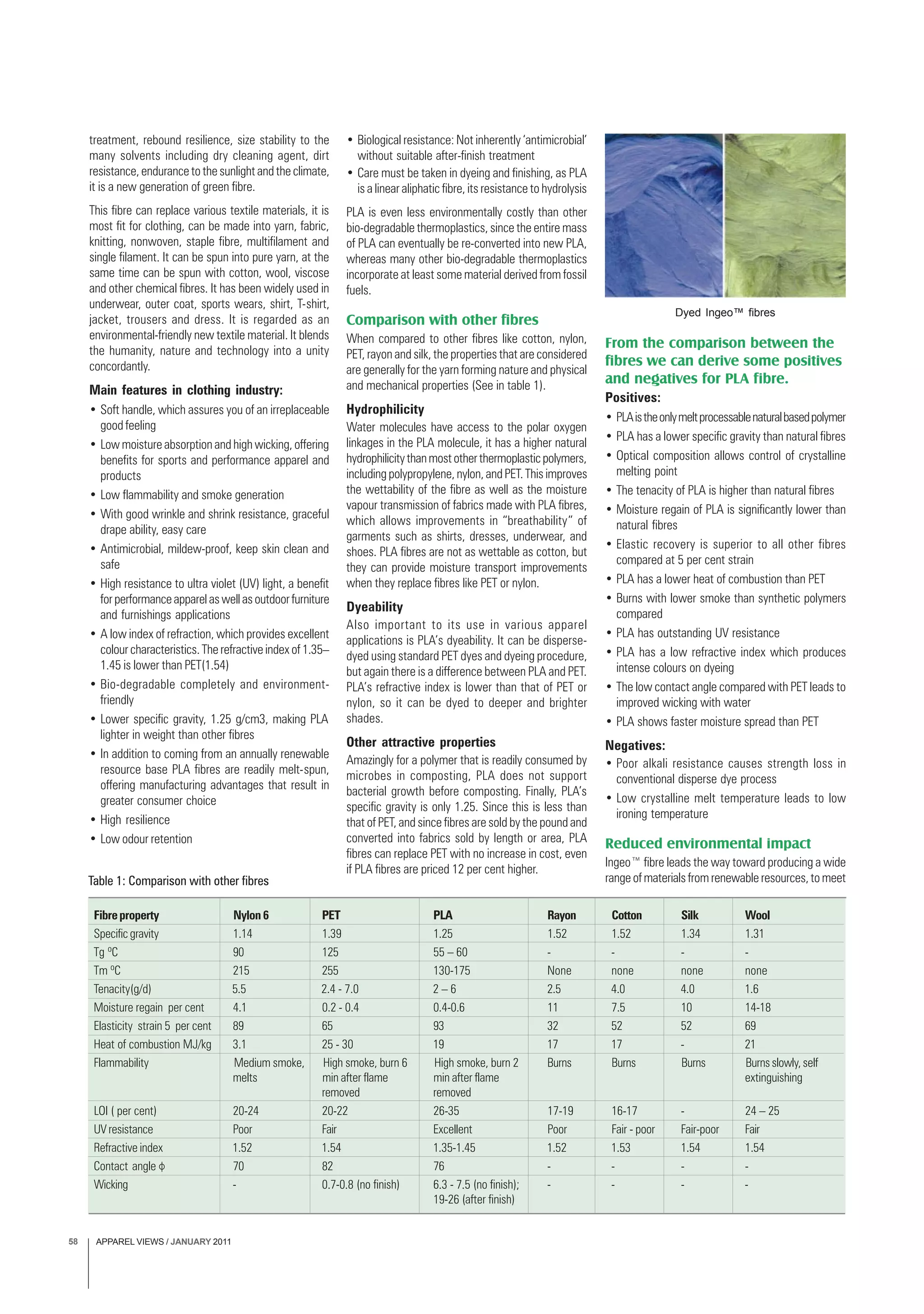

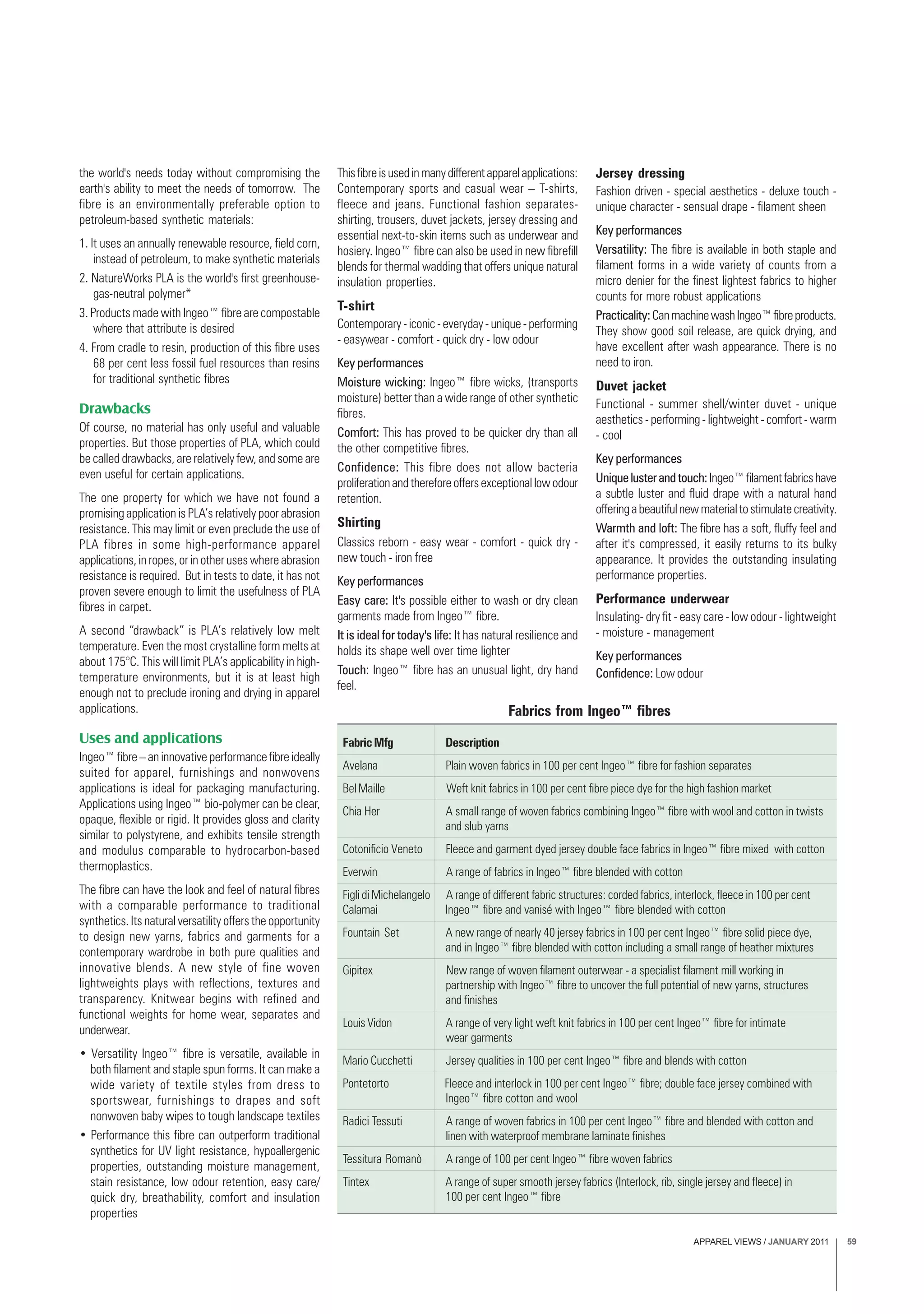

1) Ingeo is a bio-based fiber derived from corn starch that can be processed like polyester.

2) It has properties like moisture wicking, UV resistance, and is softer than synthetic fibers.

3) Ingeo fiber is used in applications like t-shirts, underwear, and outerwear due to its performance and environmental benefits compared to petroleum-based fibers.