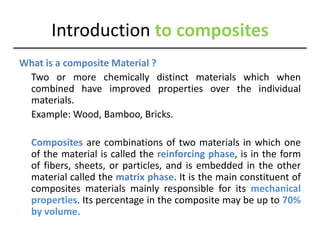

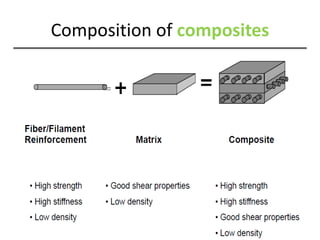

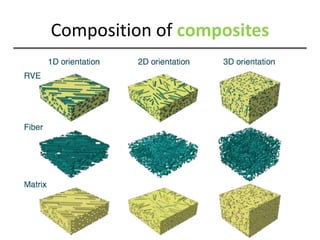

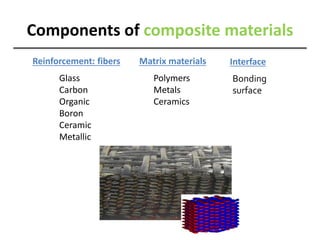

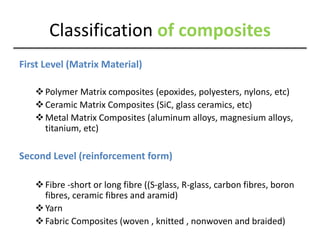

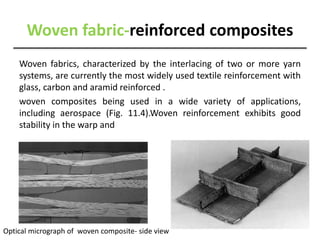

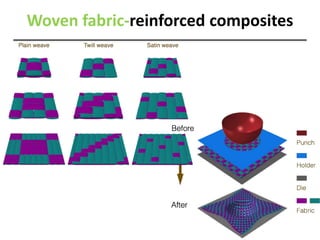

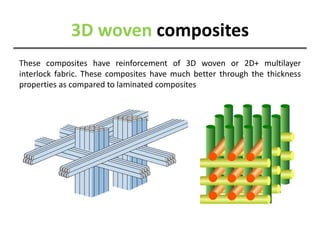

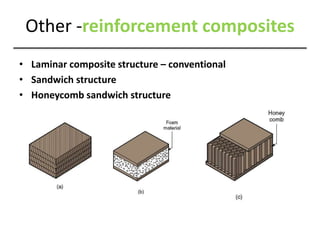

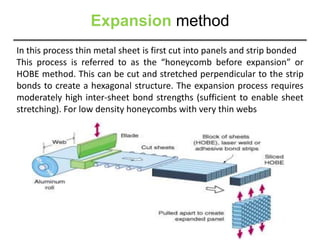

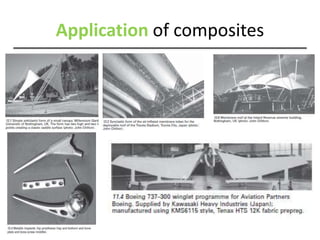

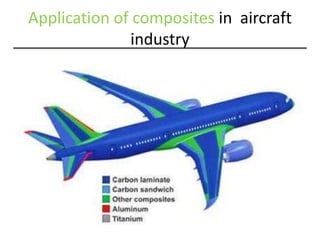

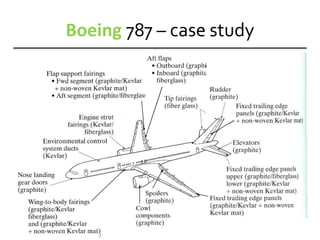

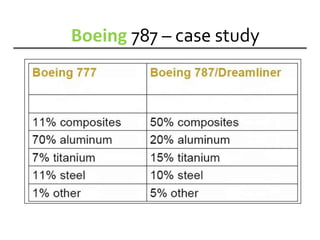

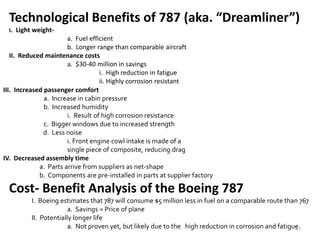

This document discusses various types of textile reinforcements and composites materials, including woven, knitted, braided and stitched fabrics. It describes the components, classification, manufacturing processes and applications of composites. Specifically, it provides details on woven fabric-reinforced composites, their mechanical properties, and how they are widely used in aerospace applications. It also examines the Boeing 787 aircraft as a case study, outlining the technological and economic benefits of its extensive use of composite materials.