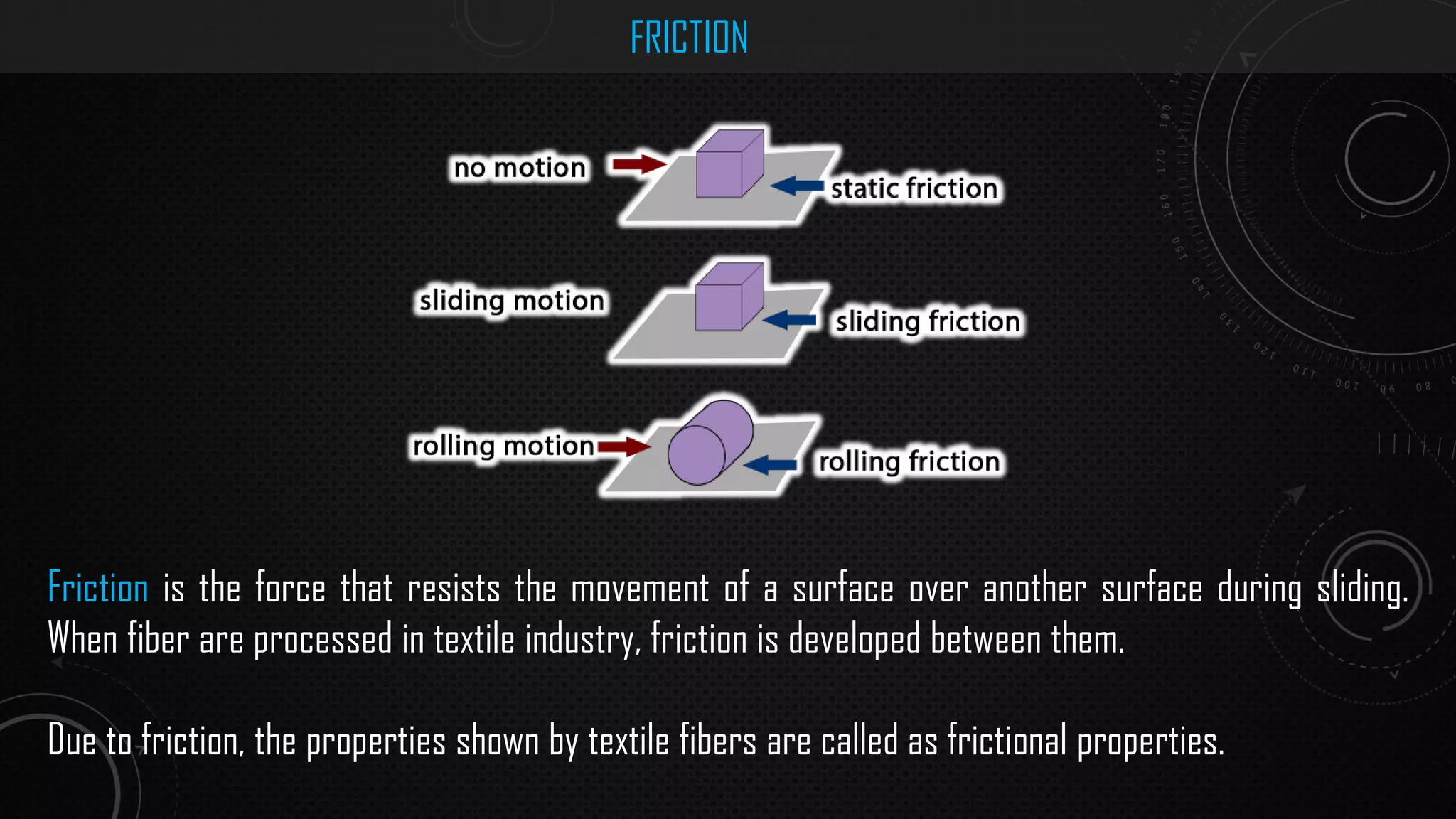

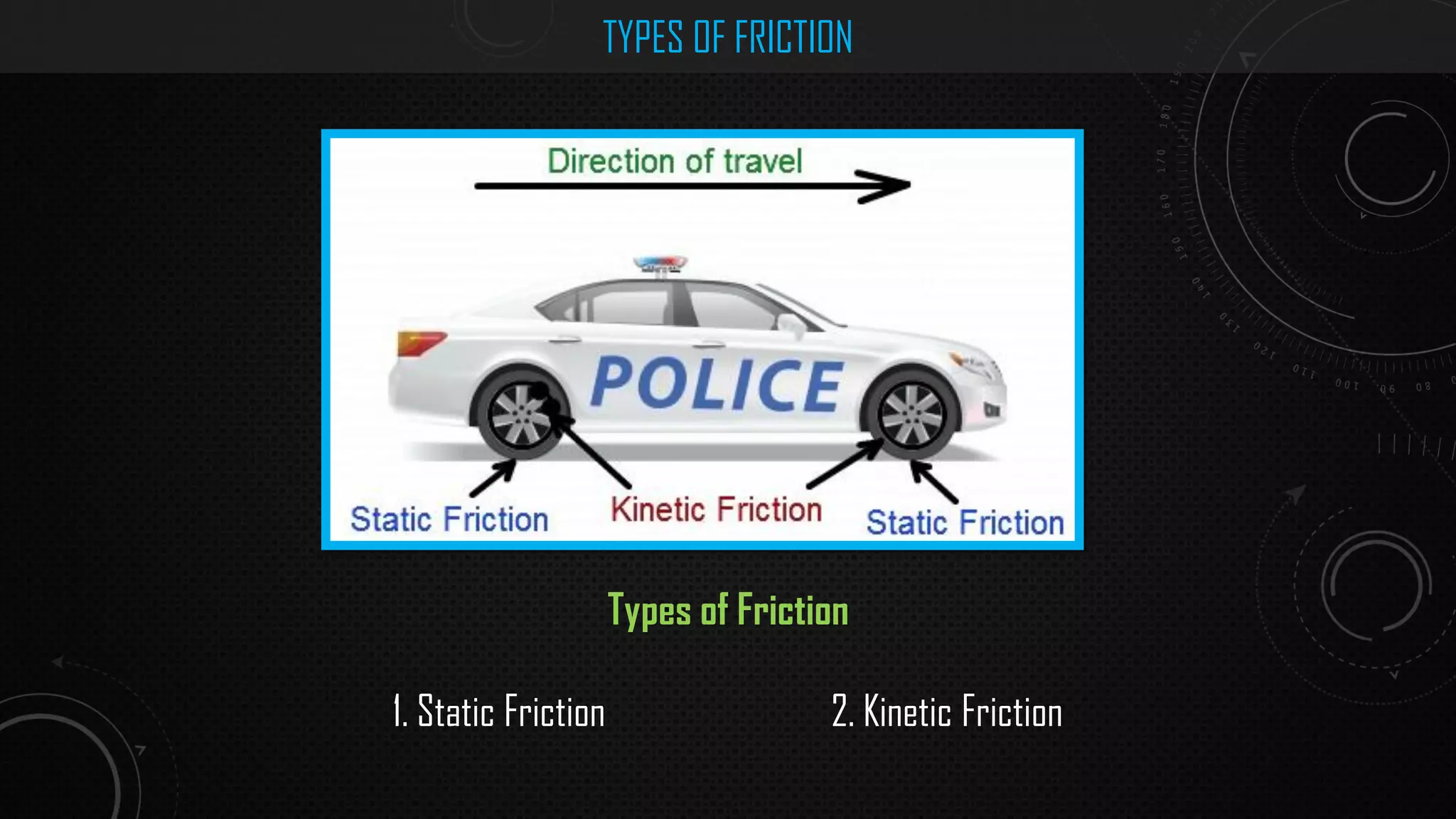

Friction is an important property of textile fibers that affects their processing and performance. The document outlines different types of friction and factors that influence the frictional intensity of textile materials, such as composition, surface properties, weight, pressure, and humidity. It also discusses how lubricants can reduce frictional forces and methods for minimizing friction during textile production, including sizing of yarns and chemical treatments of fibers. Proper control and understanding of friction is necessary for efficient textile manufacturing and maintenance of optimum frictional limits.