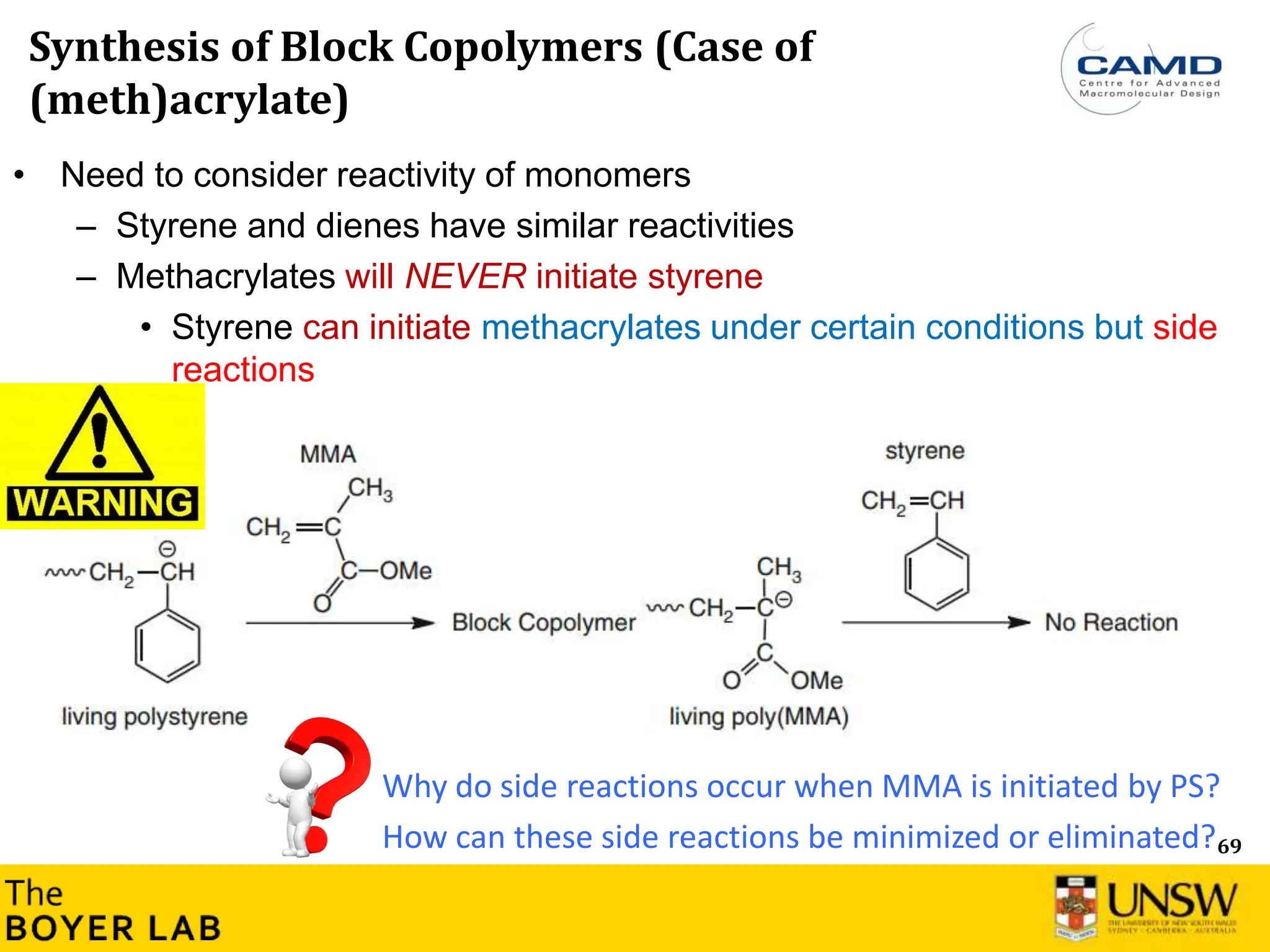

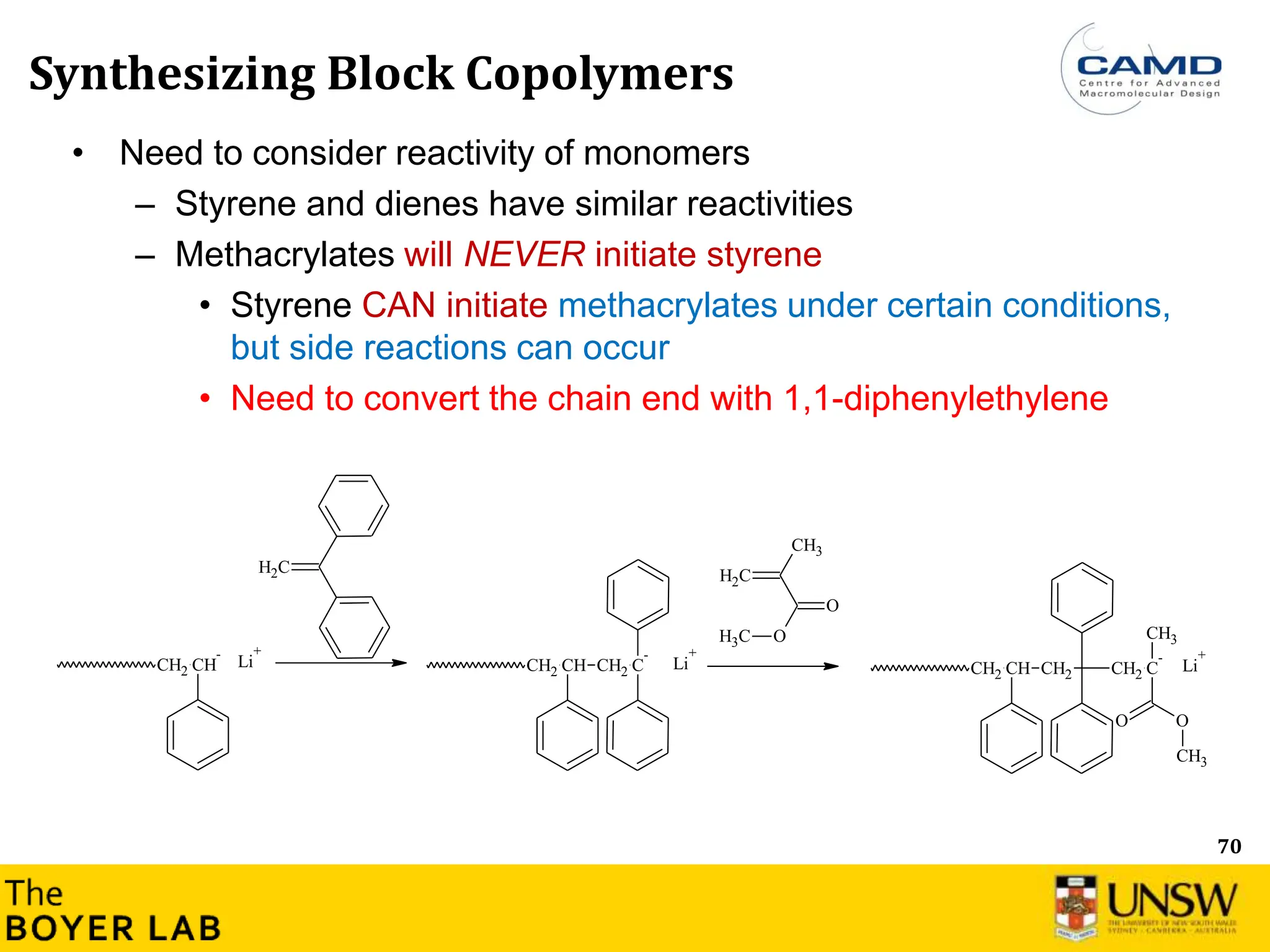

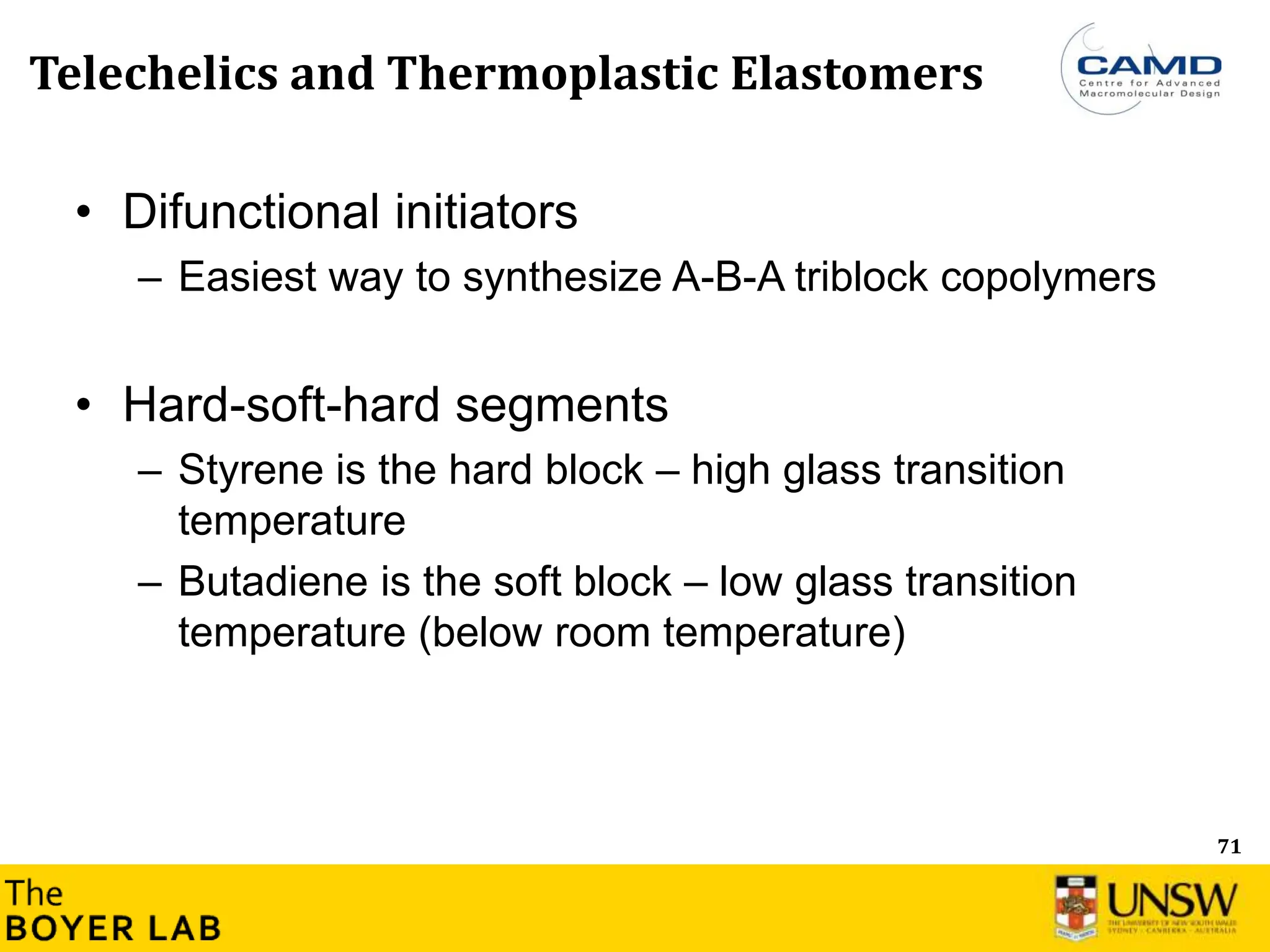

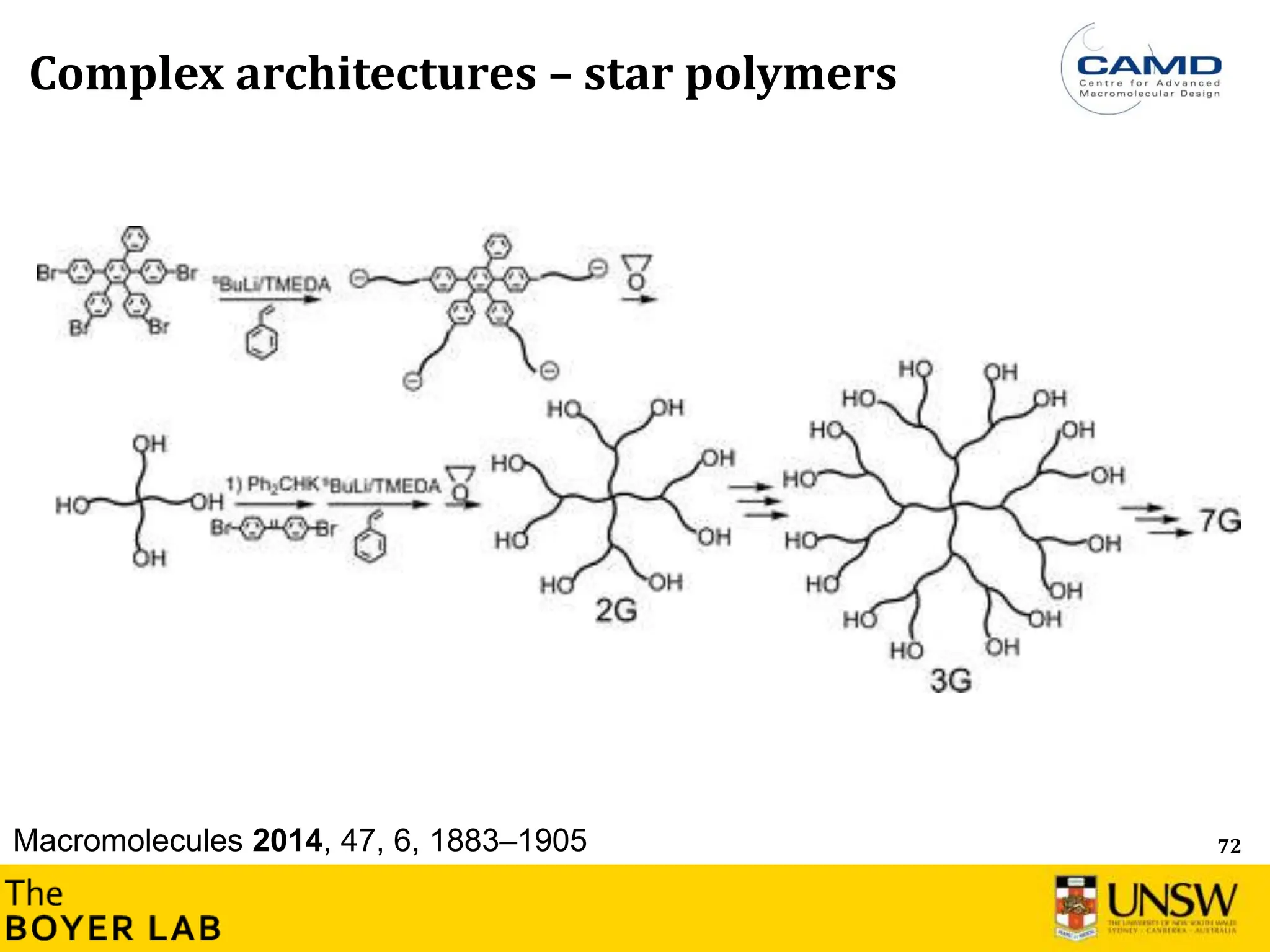

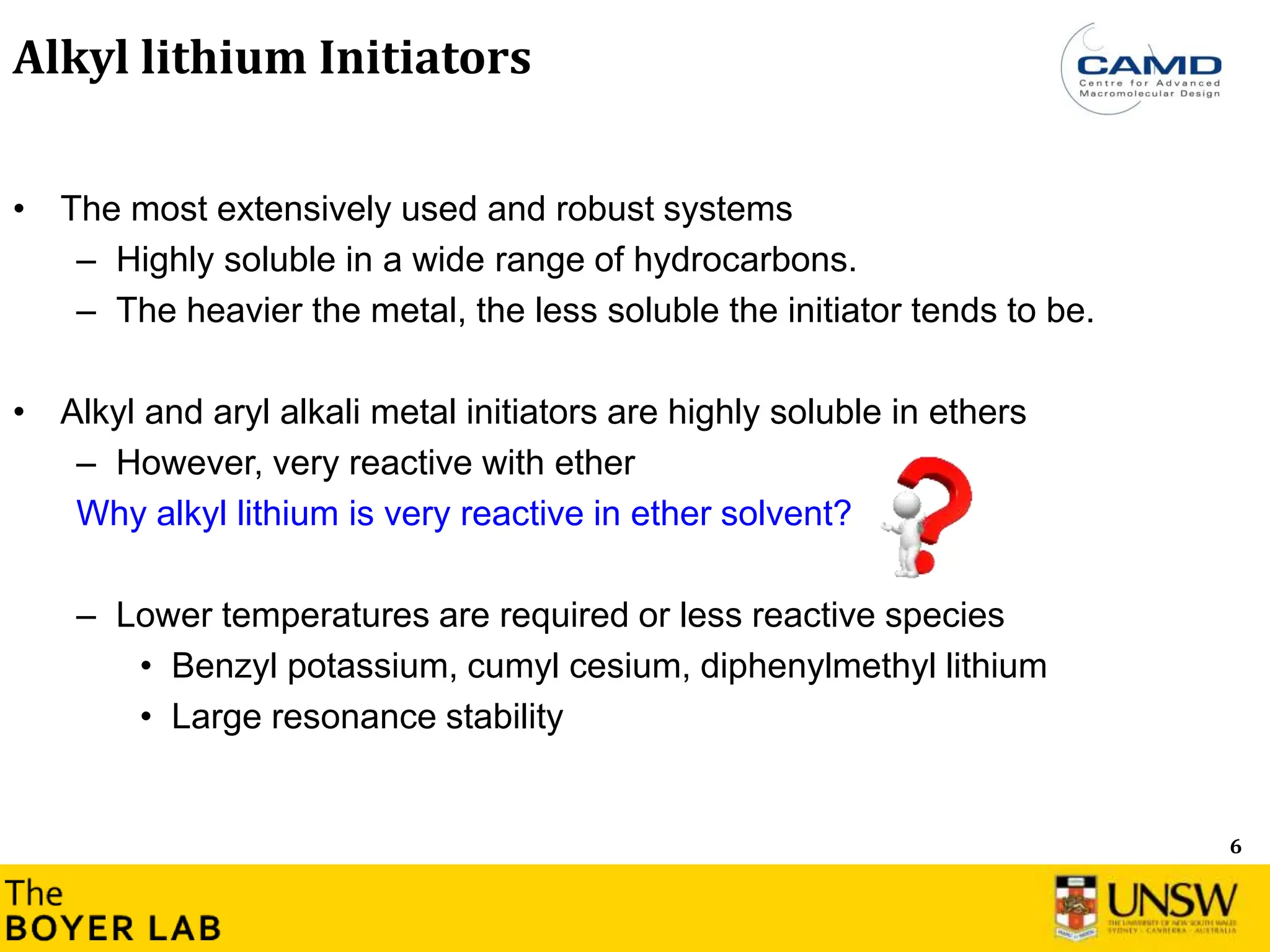

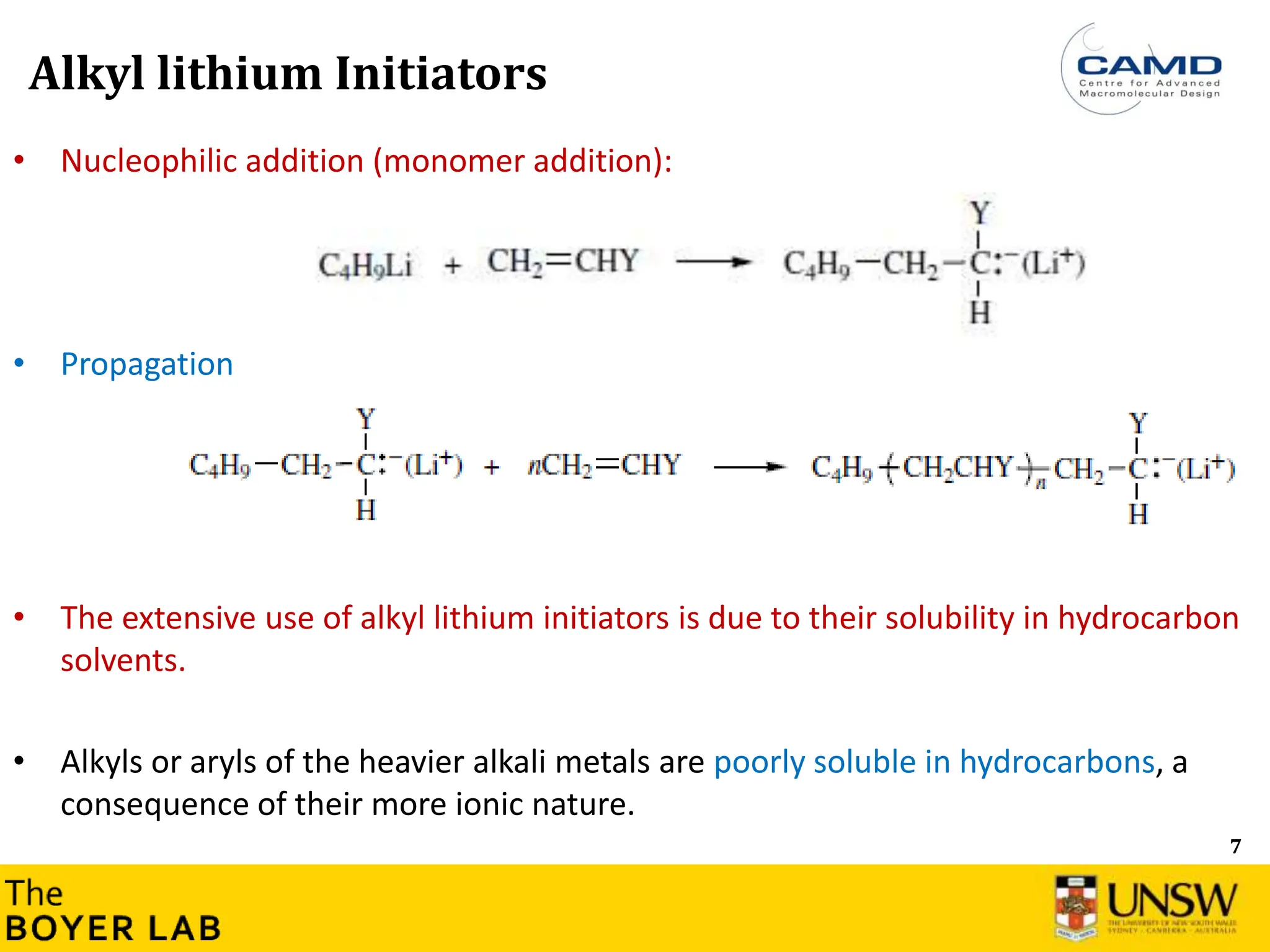

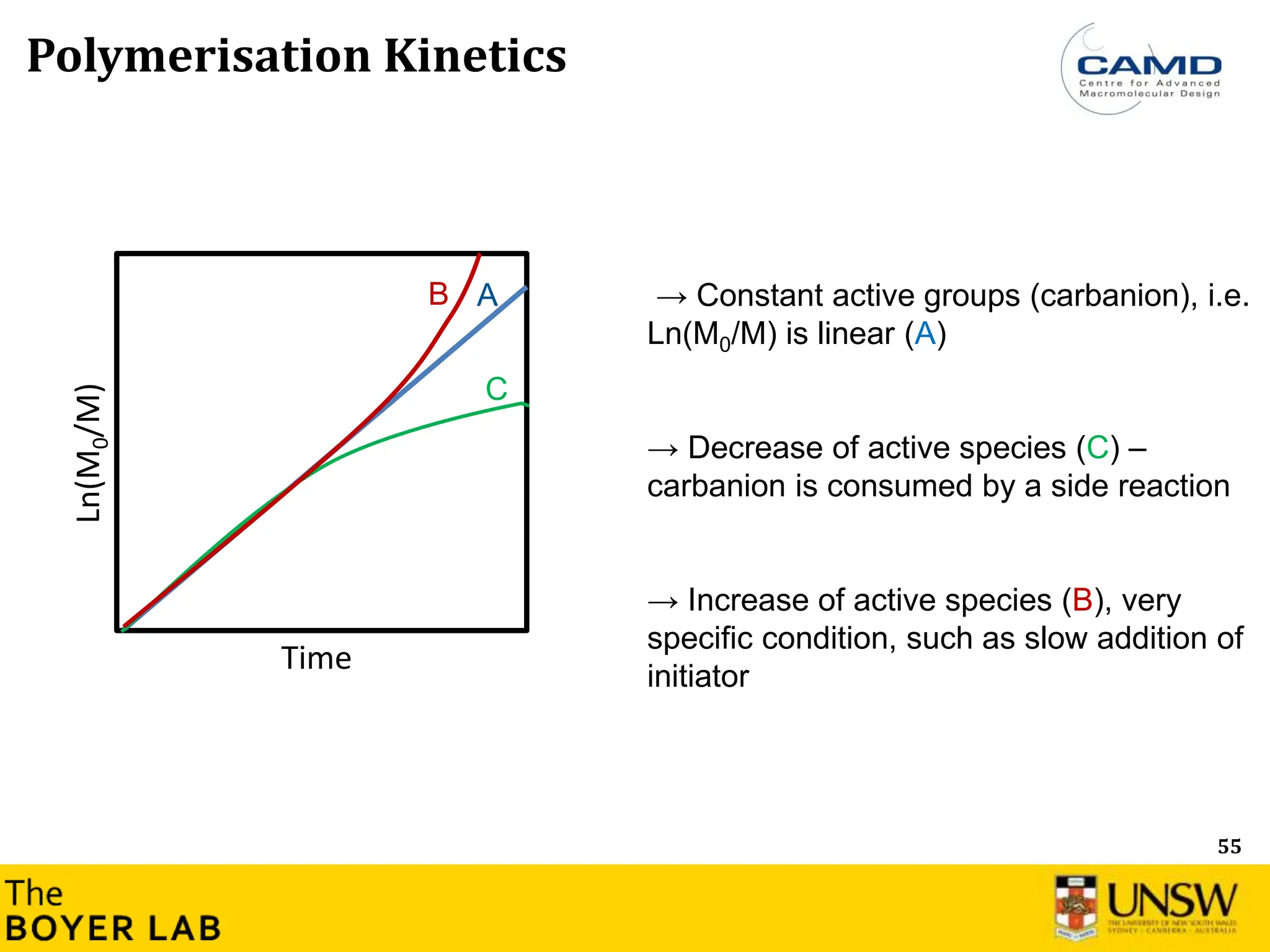

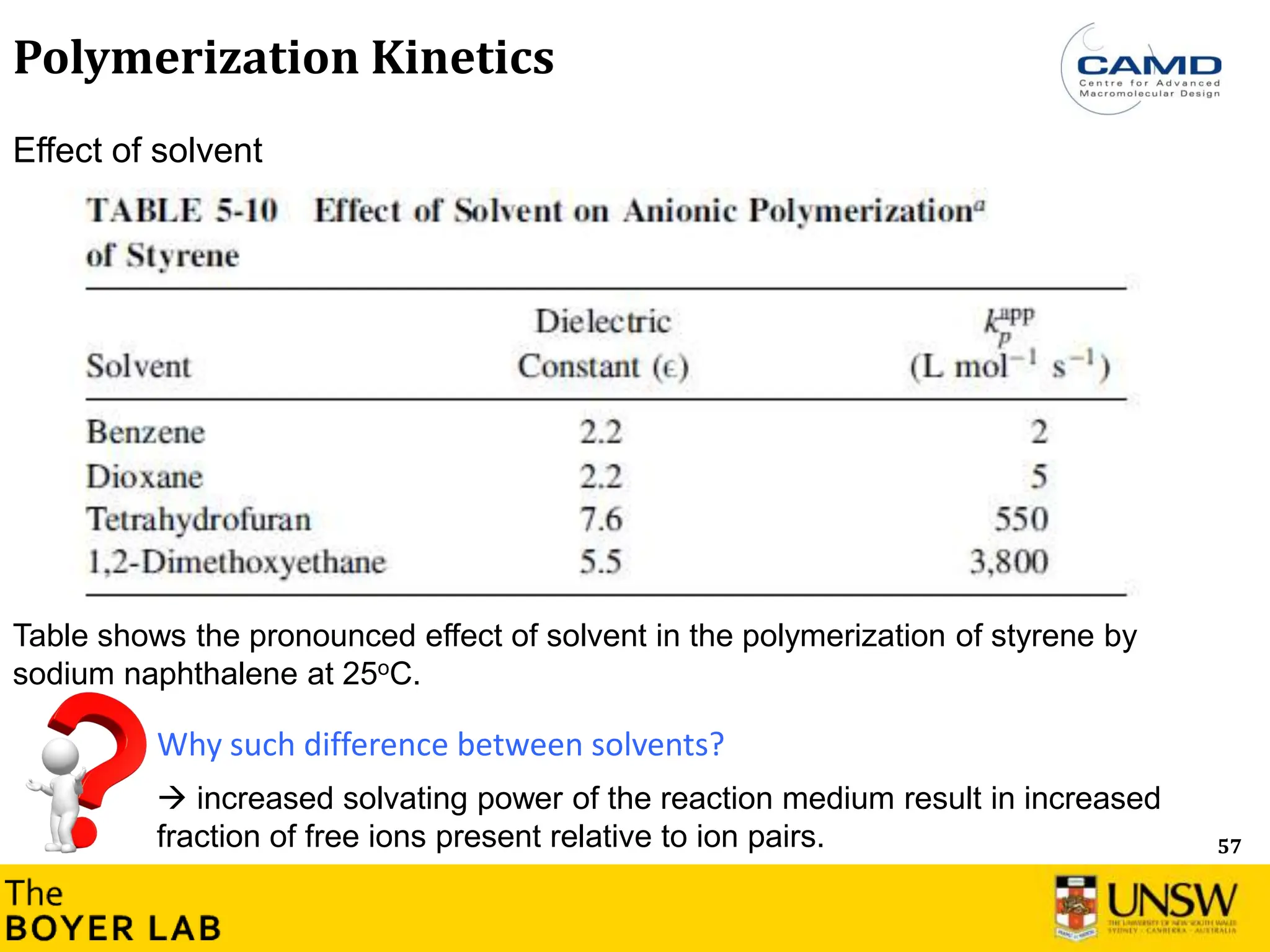

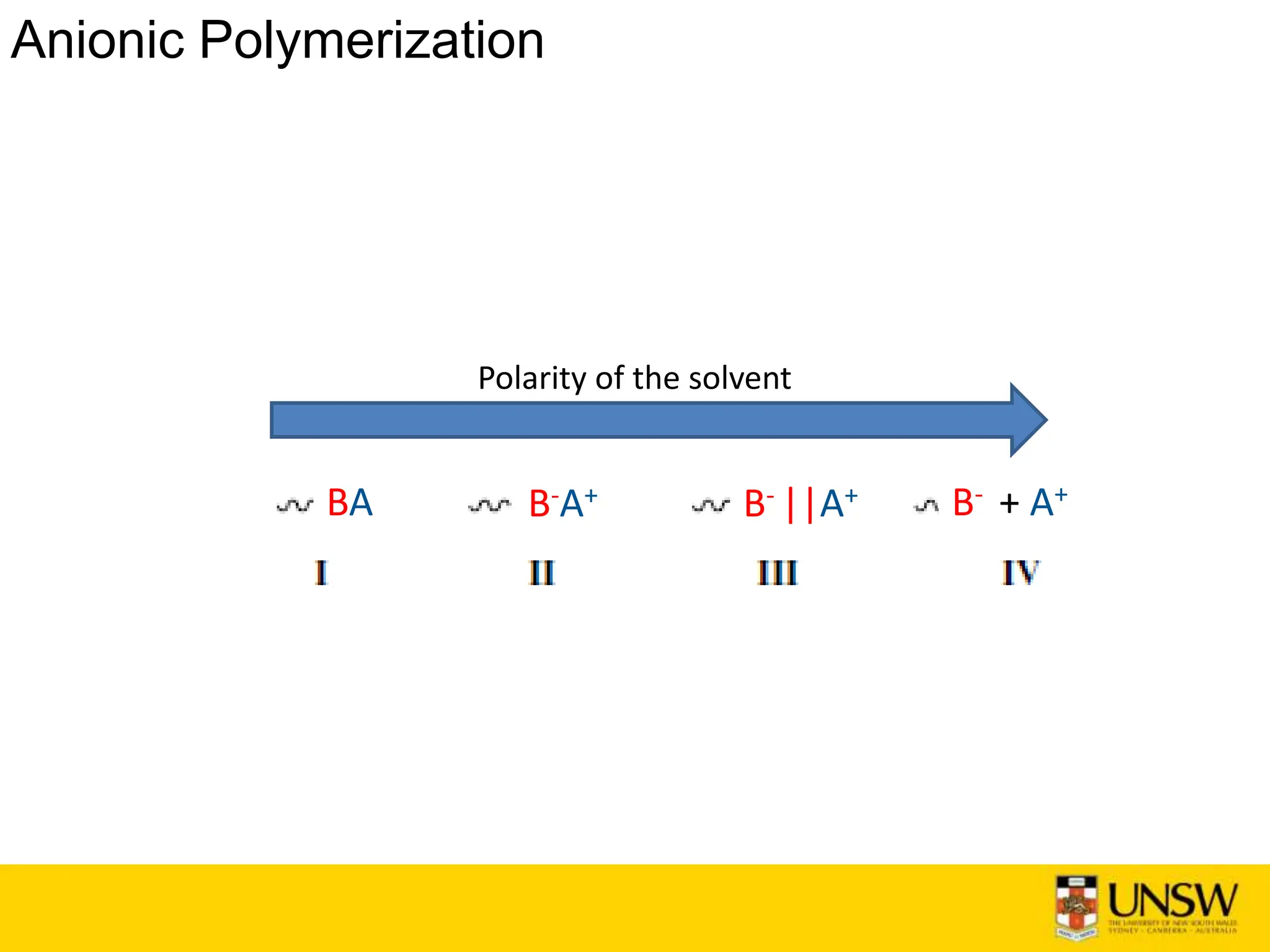

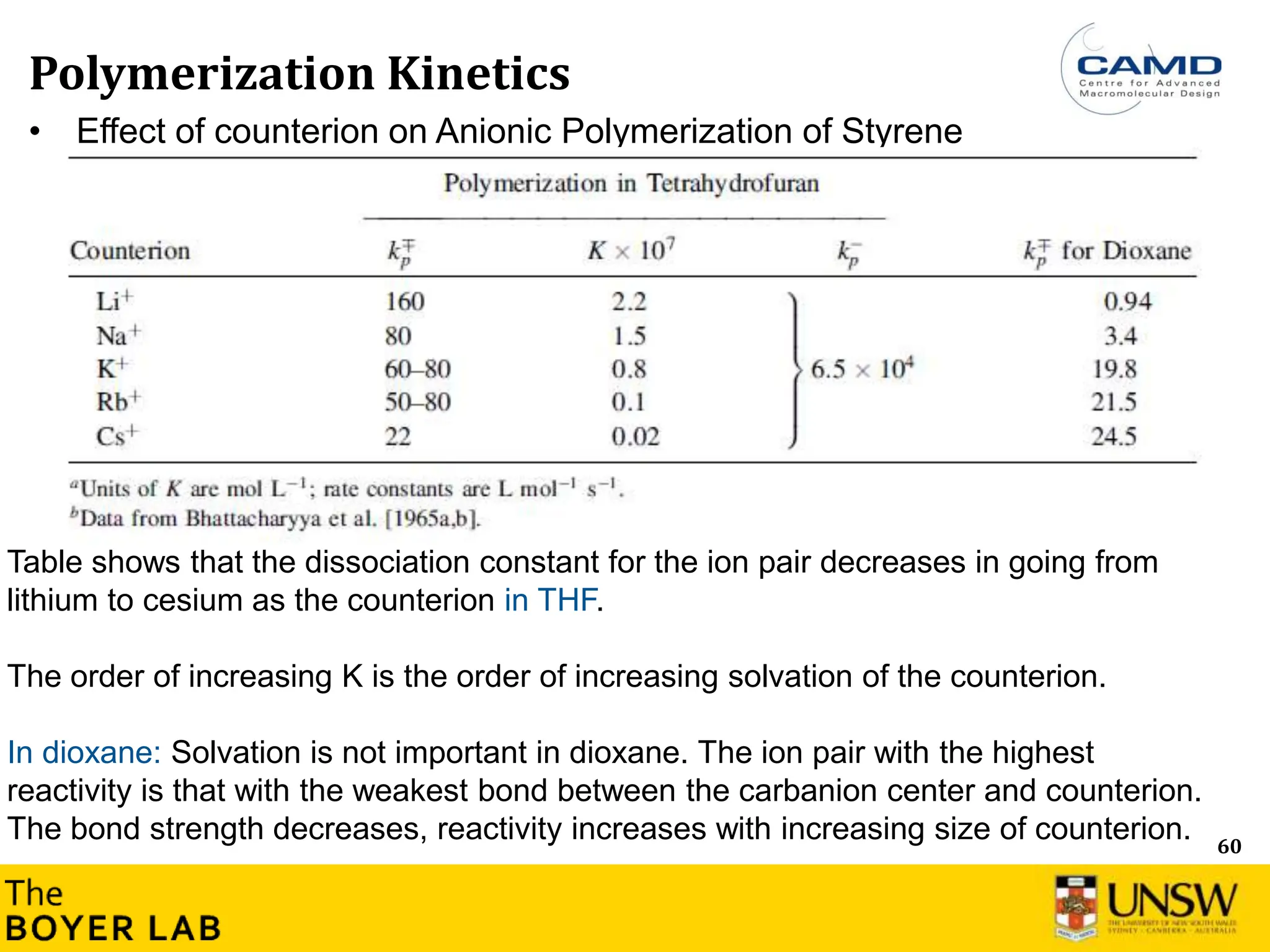

The document describes anionic polymerization, a technique developed by M. Szwarc in 1956, known for its precise molecular weight control and ability to synthesize tailored polymer architectures. Key processes include initiation using carbanion initiators and propagation without termination, allowing for the production of block and functional copolymers. Factors like initiator choice, solvent effects, and the nature of the monomers used are critical for optimizing the polymerization process and achieving desired polymer properties.

![3

Anionic Polymerisation

• Michael Szwarc reported in the year 1956 the first anionic polymerisation

https://onlinelibrary.wiley.com/doi/full/10.1002/macp.201700217

Lowest dispersity of all synthetic methods

known, described by a Poisson distribution.

Excellent molecular weight control by the

ratio of monomer and initiator, [M]/[I]

High and even extremely high molecular

weights exceeding 106 g mol–1 can be

achieved.

Complete chain end functionalization is

possible, enabling the synthesis of

AB‐diblock, ABC‐triblock and even

(AB)n‐multiblock copolymers as well as a

broad range of precisely end‐functionalized

polymers. M. Szwarc, Nature 1956, 178, 1168.](https://image.slidesharecdn.com/anionicpolymerization2024part2-240626111321-d24bca81/75/Anionic-Polymerization-2024-Chemistry-course-3-2048.jpg)

![8

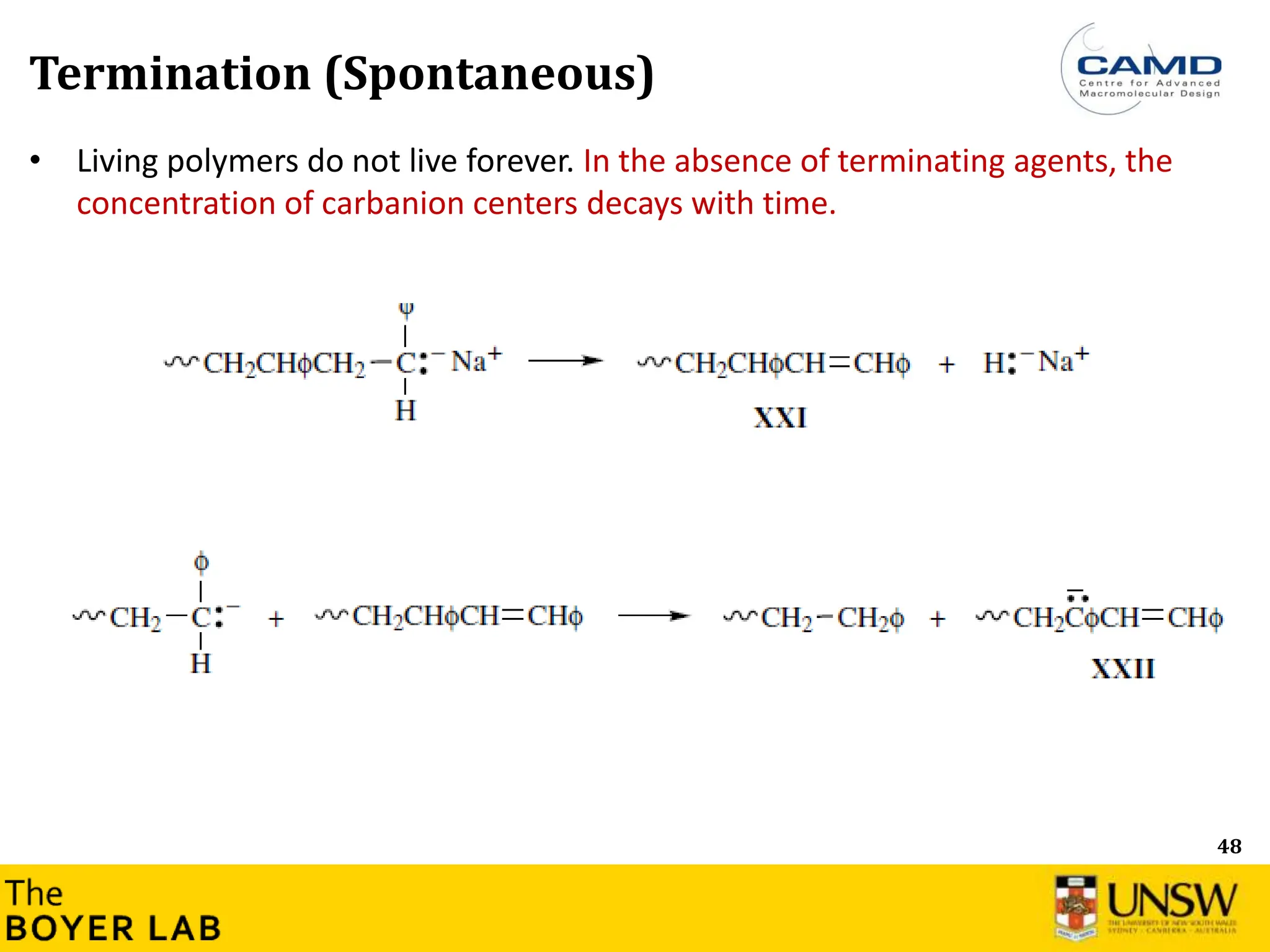

Initiation and propagation

What is the consequence on the consumption of the initiator during the

polymerisation? Can you plot [initiator] versus time (qualitatively)?

How this compares with radical polymerisation? Can you plot [Initiator]

versus time (qualitatively)?

→ Initiation step is usually very fast and much faster than the propagation in anionic

polymerisation](https://image.slidesharecdn.com/anionicpolymerization2024part2-240626111321-d24bca81/75/Anionic-Polymerization-2024-Chemistry-course-8-2048.jpg)

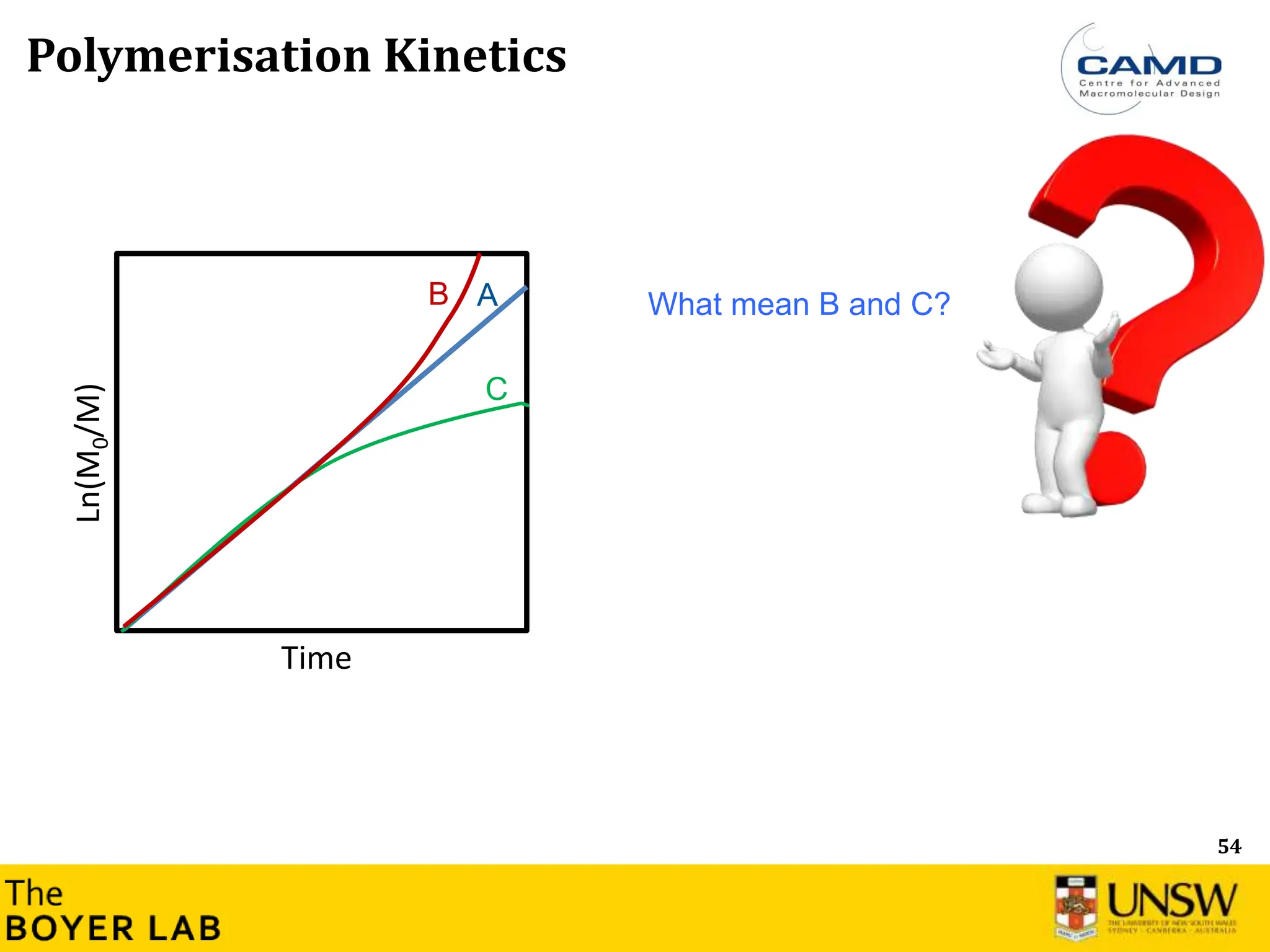

![53

Polymerization Kinetics

Ln([M]

0

/[M]

t

)

Time

Ln([M]0/[M]t) = kp

app × time → Constant concentration of active group

Ln([M]0/[M]t) = Rp= kp

app× [M-] × [M]

[M-] corresponds to active species, where [M] is the total concentration of all types of

living anionic propagating centers (free ions and ion pairs).

→ Most of anionic polymerization: Constant active groups (carbanion), i.e. Ln(M0/M) is

linear](https://image.slidesharecdn.com/anionicpolymerization2024part2-240626111321-d24bca81/75/Anionic-Polymerization-2024-Chemistry-course-53-2048.jpg)

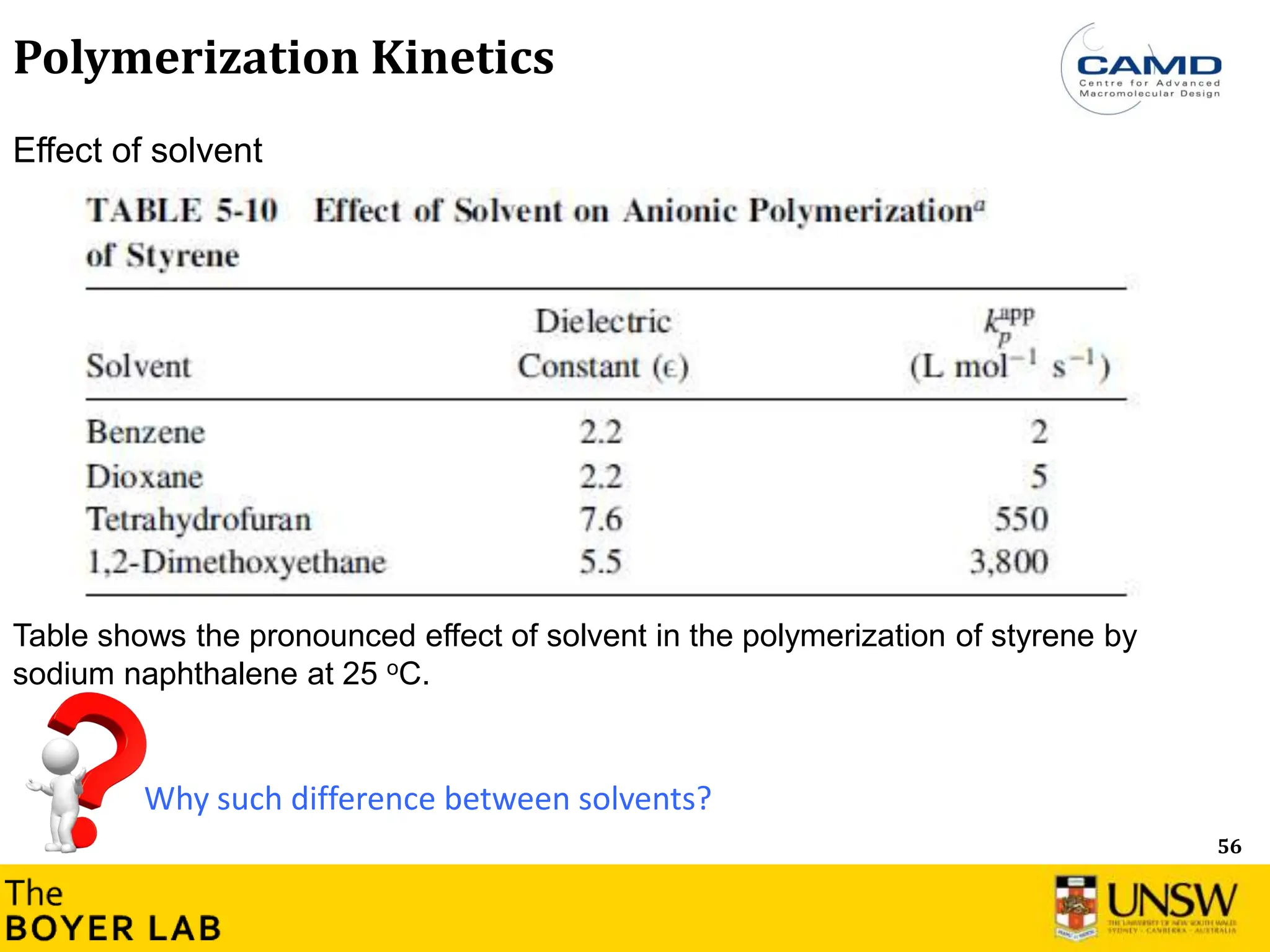

![59

Factors affecting kp

app

• [M-] is combination of [P-] + [P-(C+)] [M-] = [P-] + [P-(C+)]

• Rp = kp

-[P-][M] + Kp

±[P-(C+)][M] (1)

• Rp = = kp

app× [M-] × [M] (2)

Combined (1) and (2)

• kp

app=

[kp

−[P−]+ Kp

±[P−(C+)]

[M−]

• P-(C+) ↔ P- + C+ Dissociation constant: 𝐾 =

𝑃

−

[𝐶

+

]

[𝑃

−

𝐶

+

]

,

• if [P-]=[C+] 𝐾 =

𝑃

−

2

[𝑃

−

𝐶

+

]

𝑃

−

= √(𝐾 × 𝑃

−

𝐶

+

)](https://image.slidesharecdn.com/anionicpolymerization2024part2-240626111321-d24bca81/75/Anionic-Polymerization-2024-Chemistry-course-59-2048.jpg)

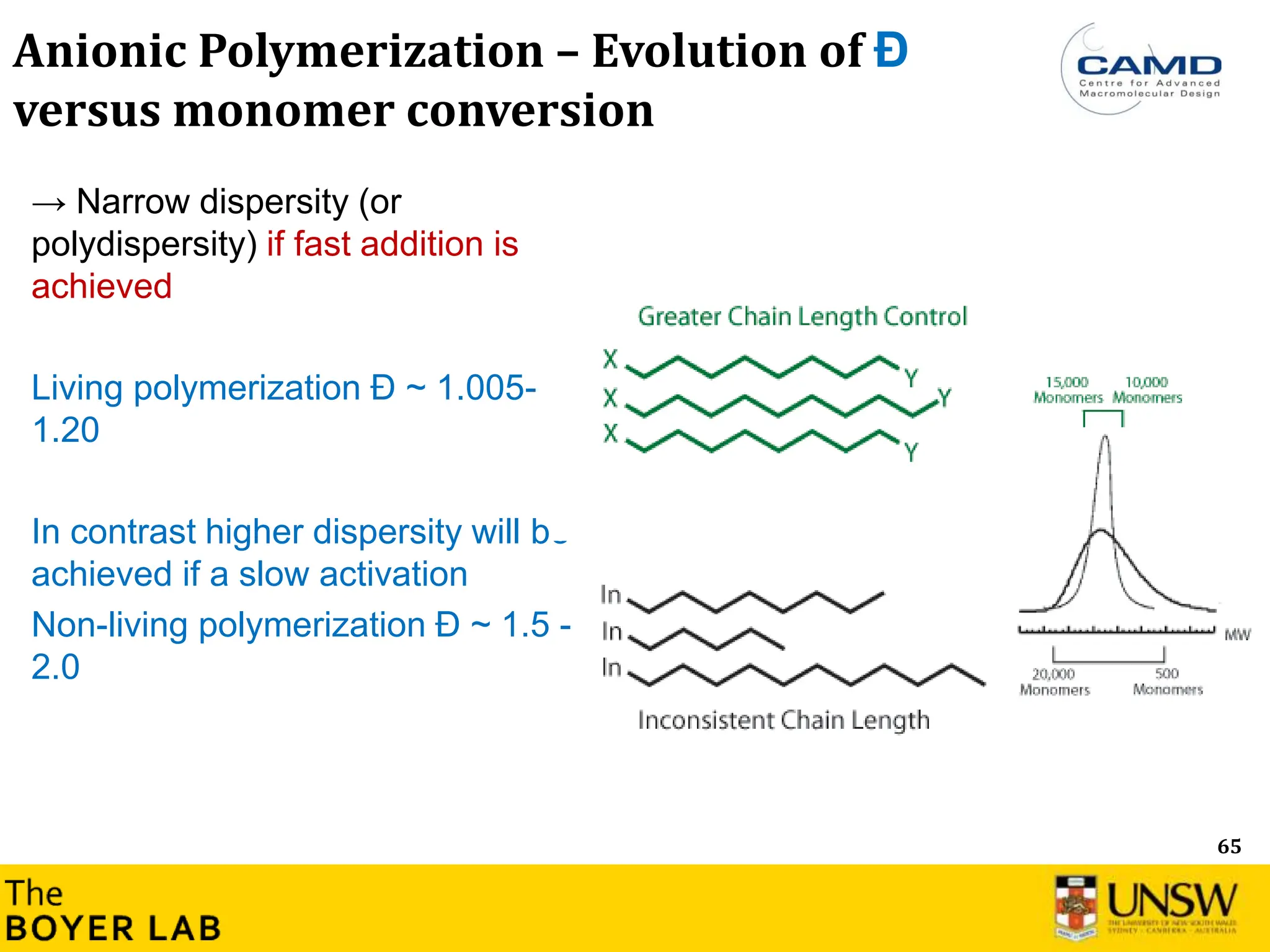

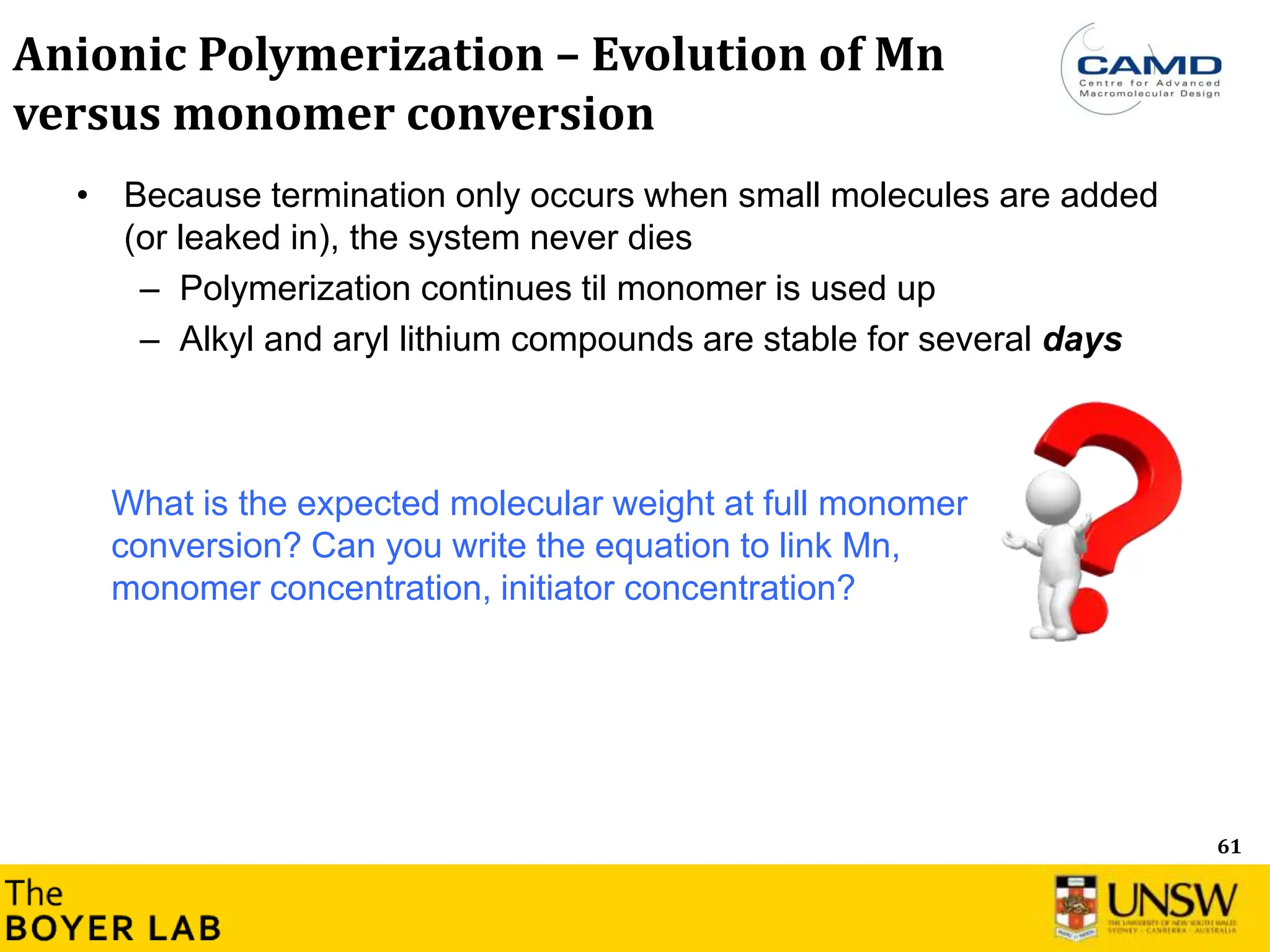

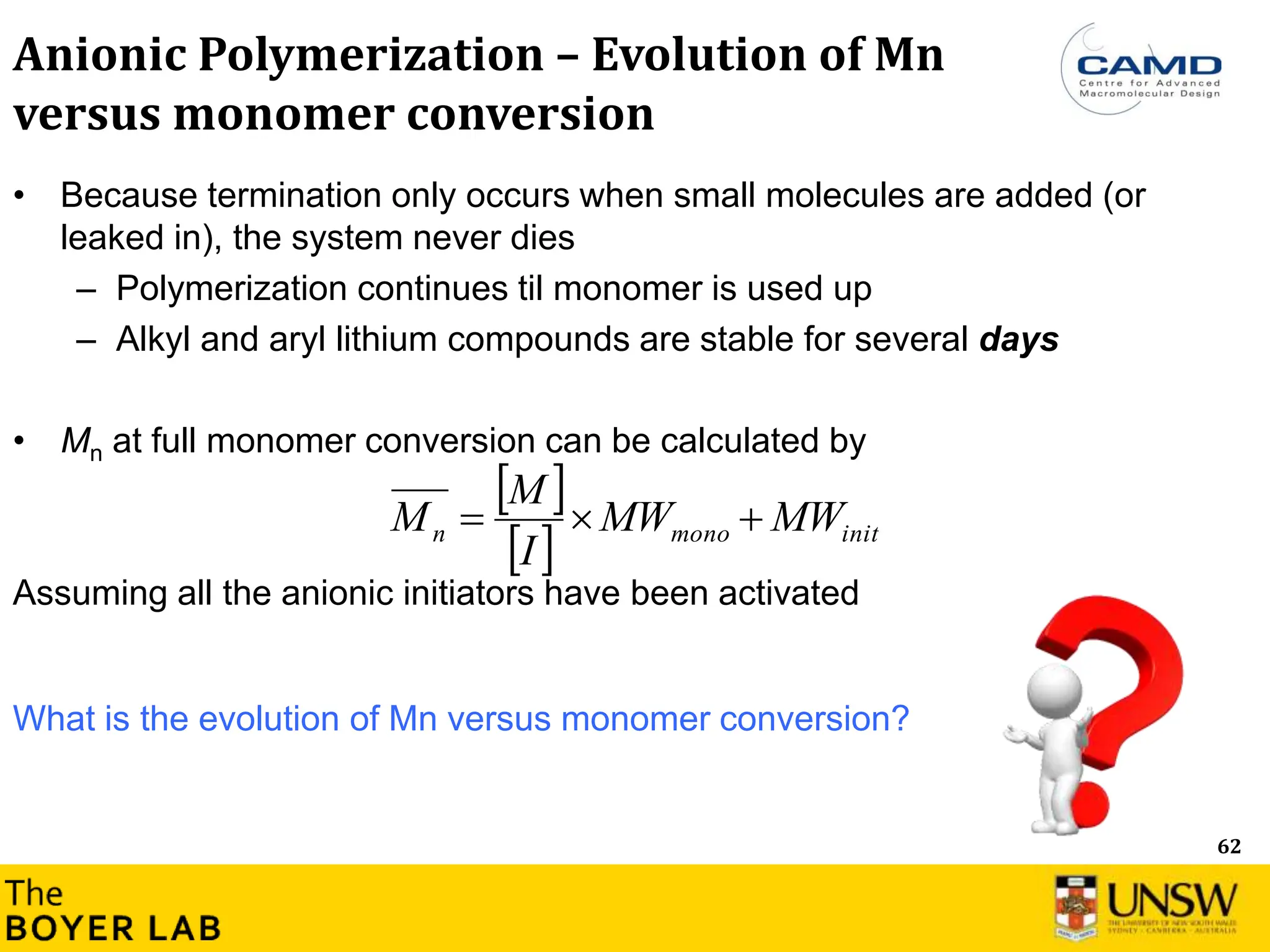

![63

Molecular

weight

Monomer conversion

• Linear evolution of Mn versus monomer

conversion

→ Prediction of the molecular weight versus

monomer conversion

Mn = ([M]0/[Initiator]0) × α × MW (Monomer)

+ MW (Initiator)

What is the condition for this equation to be

valid?

Anionic Polymerization – Evolution of Mn

versus monomer conversion](https://image.slidesharecdn.com/anionicpolymerization2024part2-240626111321-d24bca81/75/Anionic-Polymerization-2024-Chemistry-course-63-2048.jpg)

![64

Molecular

weight

Monomer conversion

• Linear evolution of Mn versus monomer

conversion

→ Prediction of the molecular weight versus

monomer conversion

Mn = [M]0/[Initiator]0 × α × MW (Monomer) +

MW (Initiator)

Anionic Polymerization – Evolution of Mn

versus monomer conversion

Condition: In anionic polymerisation, the initiation is fast (all chains are activated at the

beginning of the polymerization) in comparison to the rate of chain propagation.

What is the consequence for the dispersity (or polydispersity)?](https://image.slidesharecdn.com/anionicpolymerization2024part2-240626111321-d24bca81/75/Anionic-Polymerization-2024-Chemistry-course-64-2048.jpg)