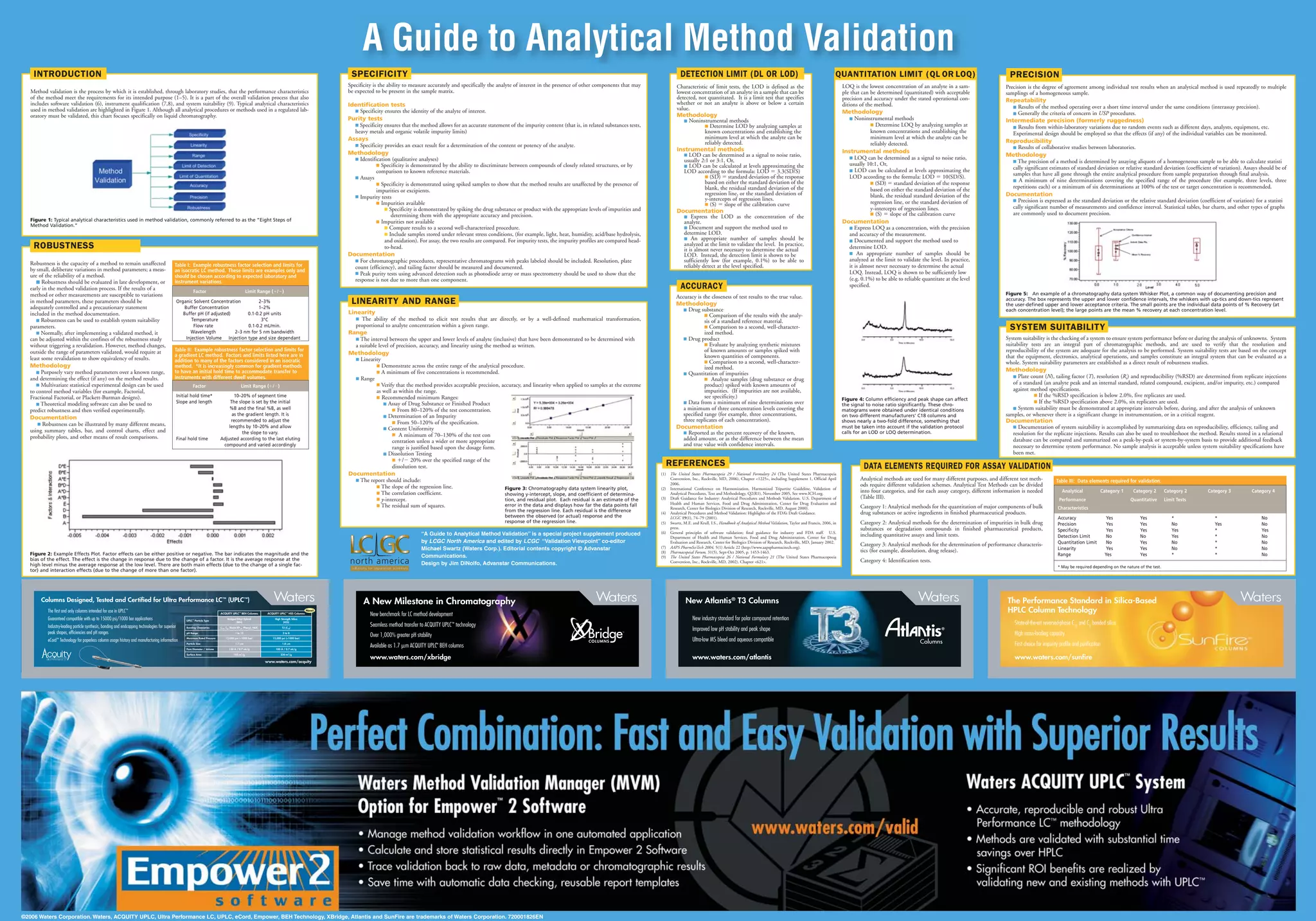

This document provides an overview and summary of key concepts related to analytical method validation for liquid chromatography. It discusses topics such as specificity, linearity and range, precision, accuracy, detection limit, quantitation limit, robustness, and system suitability. Examples and definitions are provided for each concept. Chromatograms, plots, and tables are also included to help illustrate key points.