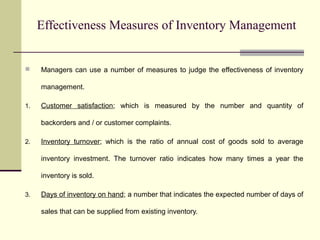

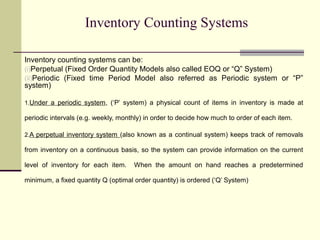

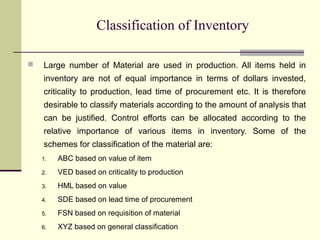

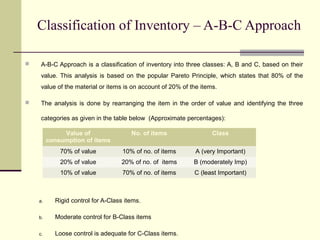

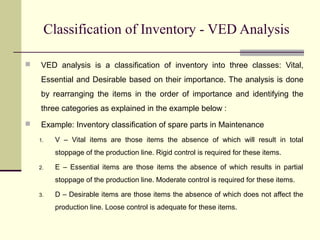

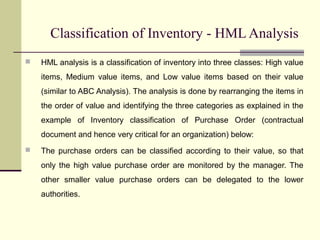

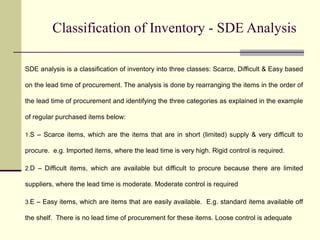

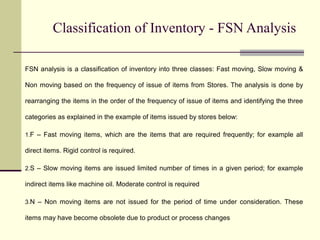

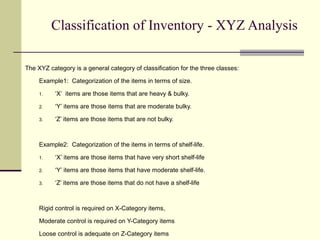

This document discusses inventory management. It defines inventory and explains that good inventory management is important for business success. It outlines various inventory classification systems like ABC analysis, which sorts inventory into A, B, and C categories based on value. Additional classification systems covered include VED, HML, SDE, FSN, and XYZ analysis, which categorize inventory based on factors like criticality, value, procurement lead time, and movement frequency. The document also discusses inventory counting systems and key effectiveness measures for evaluating inventory management.

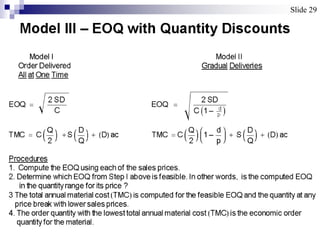

![Model III – EOQ with Quantity Discounts

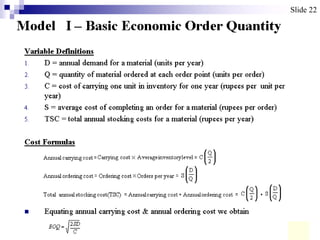

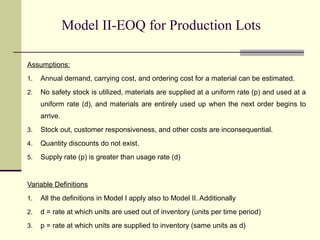

Assumptions:

1. Annual demand, carrying cost, and ordering cost for a material can be

estimated.

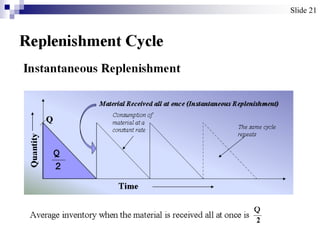

2. Average inventory levels can be estimated at either:

a. Q/2 – if the assumption of Model I prevail : no safety stock, orders are received

all at once, materials are used a uniform rate, and materials are entirely used

up when the next order arrives.

b. Q/2 [(p – d)/p] – if the assumption of Model II prevail : no safety stock, materials

are supplied at a uniform rate (p) and used at a uniform rate (d), and materials

are entirely used up when the next order arrives.

3. Stock out, customer responsiveness, and other costs are inconsequential.

4. Quantity discounts do exist. As larger quantities are ordered, price breaks

apply to all units ordered.](https://image.slidesharecdn.com/00inventorymanagement1-160921135452/85/inventory-management-26-320.jpg)