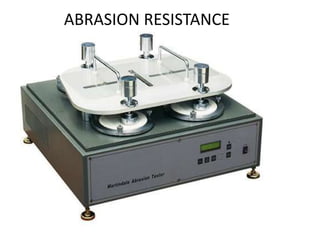

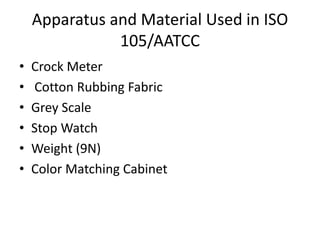

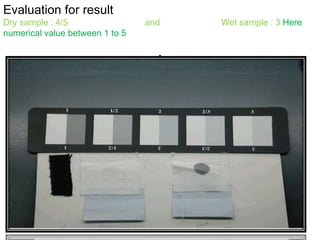

This document discusses various textile testing methods. It provides details on breaking strength testing, including that it is mainly used for woven fabrics to test unidirectional strength. It also discusses the importance of breaking strength testing for end uses like safety belts. Abrasion resistance testing and its importance for fabrics used in garments is covered as well. Finally, it summarizes color fastness to dry cleaning testing and the equipment used.