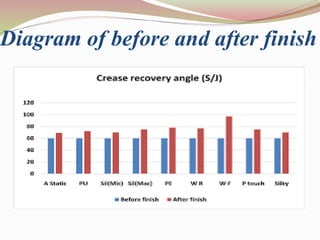

This document discusses the crease recovery of fabrics and the test method. It begins with an introduction of the presenter and topic. Then, it defines crease recovery as a fabric's ability to return to its original position after creasing. It describes the Shirley crease recovery tester used to measure the crease recovery angle. A higher recovery angle indicates better crease recovery. Finally, it outlines the procedure to test crease recovery, which involves creasing a fabric sample between glass plates with weight, then clamping it and measuring the recovery angle.