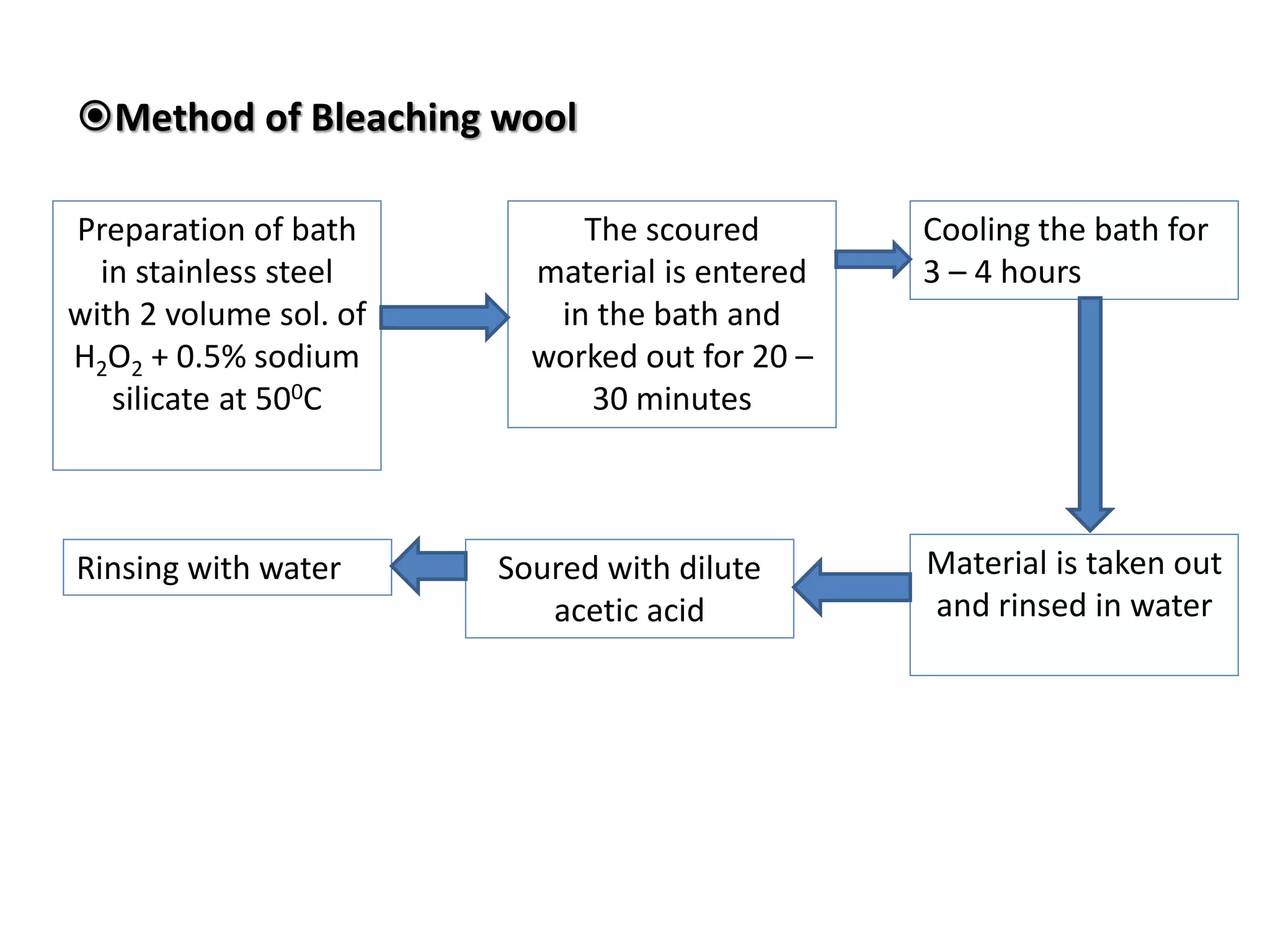

This document discusses the scouring and bleaching processes for various natural and man-made fibers. It explains that wool requires a mild scouring process due to its sensitivity to alkali. Scouring of wool uses sodium carbonate or ammonium carbonate at below boiling temperatures. Bleaching can be done with reducing agents like sodium bisulfite or hydrogen peroxide, which produces a permanent whiteness. For silk, degumming using hot soap solution is required to remove the sericin gum. Hydrogen peroxide bleaching is preferred for silk. Man-made fibers require milder scouring, and polyester rarely needs bleaching, while nylon and acrylic can be bleached using sodium chlor