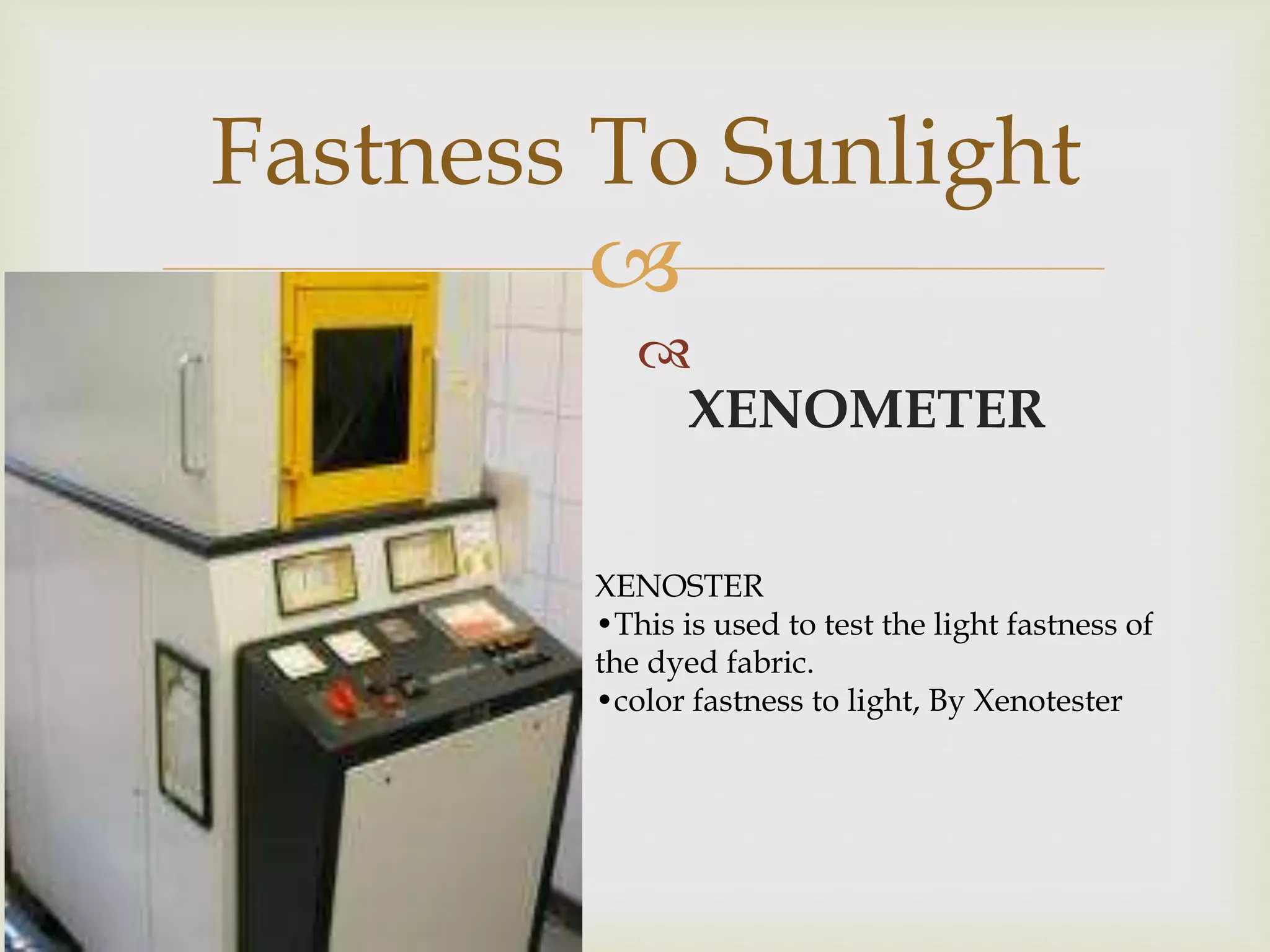

Color fastness refers to a textile's resistance to fading or color transfer during washing, light exposure, or other processes. It is important to test dyed or printed fabrics for color fastness using standardized methods. These include using a xenotester to test light fastness, a wash wheel to test washing fastness, and a crock meter to test rubbing fastness. Perspiration fastness is tested using a perspirometer. Test results are evaluated using grey scales to rate the degree of color change or transfer on a scale of 1 to 5. Proper evaluation of color fastness helps ensure textiles maintain their color as intended for the customer.