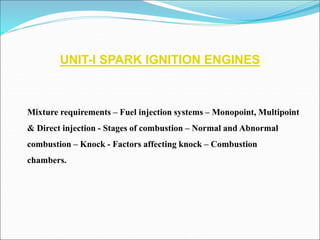

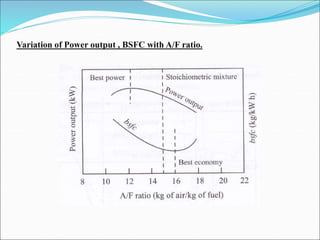

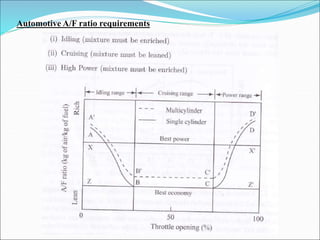

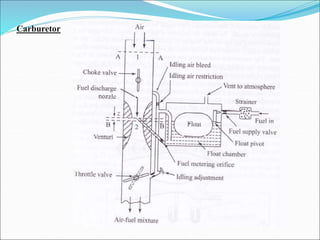

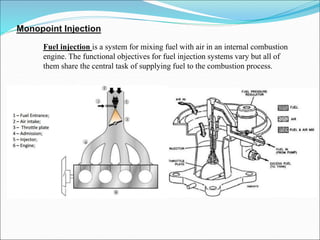

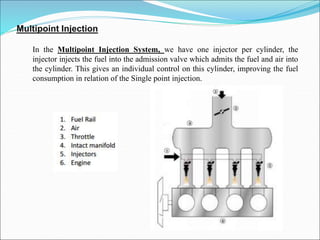

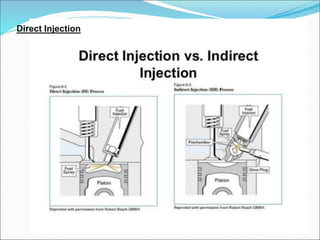

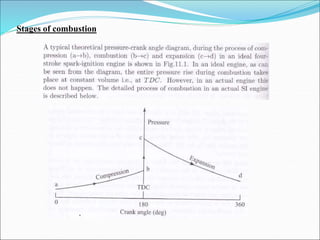

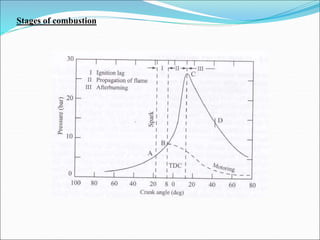

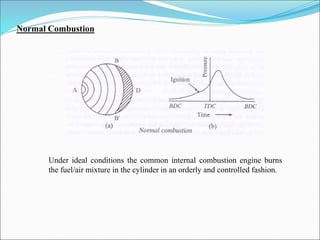

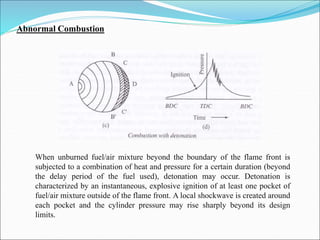

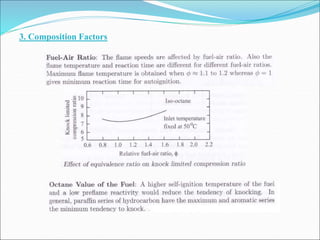

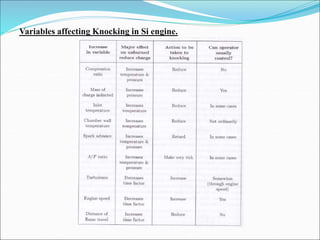

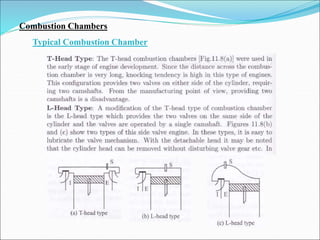

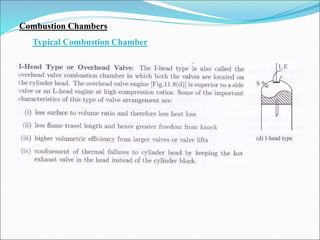

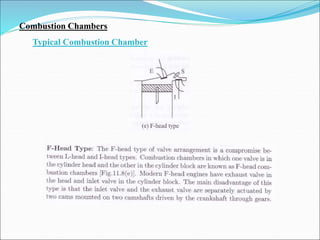

The document discusses spark ignition engines. It covers mixture requirements, fuel injection systems including monopoint, multipoint, and direct injection. It describes the stages of normal and abnormal combustion as well as factors that affect knocking. It also discusses combustion chambers and their role in smooth engine operation and high power output.